Rotating mandrel device for limited motion mandrel mill

A technology of rotating device and restraining mandrel, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of difficulty in stripping the restraining mandrel in a continuous pipe rolling mill, and achieve longer length and extended use. Longevity, effect of reducing thermal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

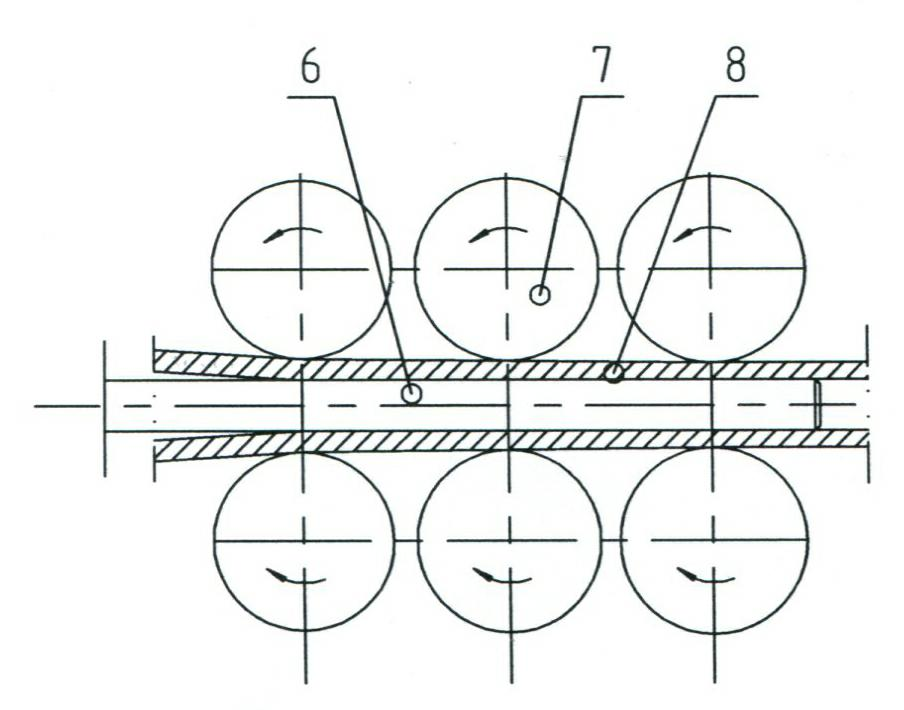

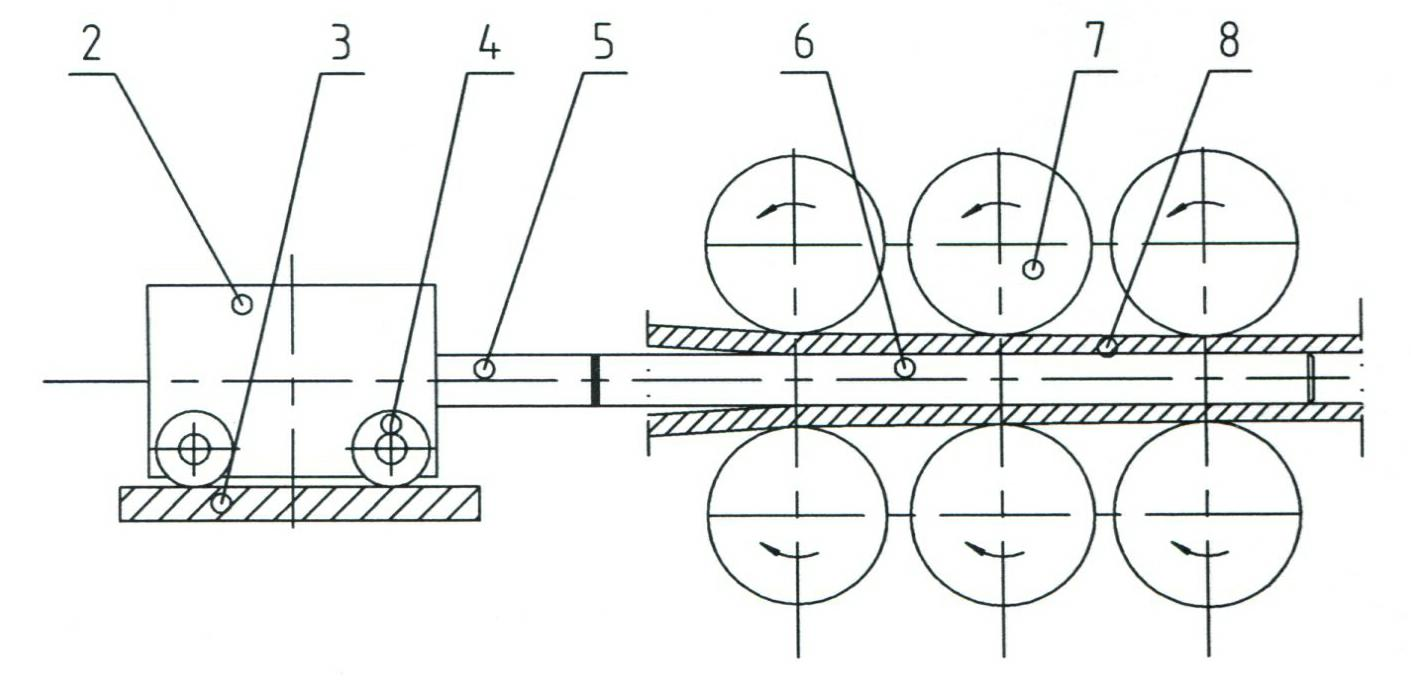

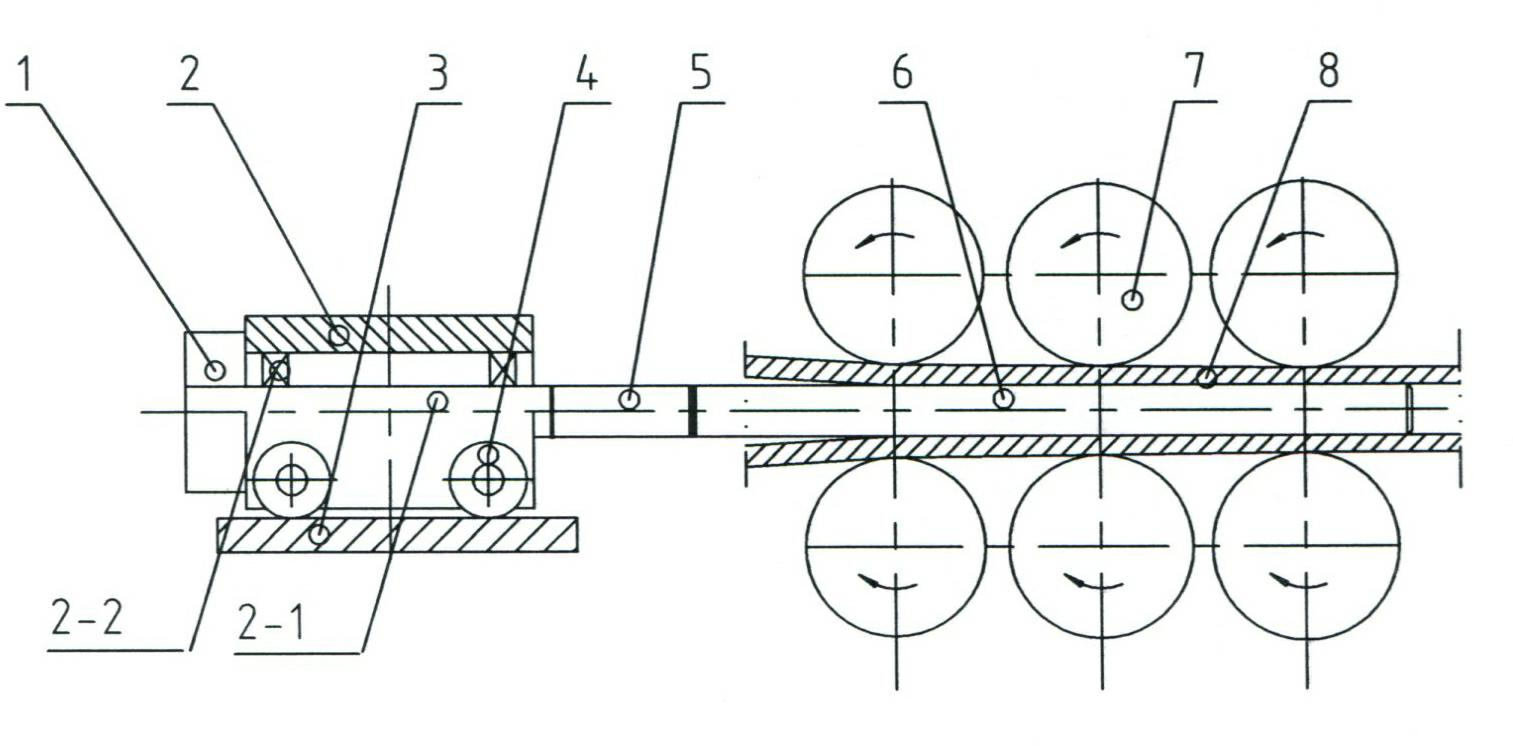

[0013] Such as image 3 As shown, a rotating mandrel device for a mandrel-limiting continuous rolling mill, including: a mandrel-limiting trolley 2, a support rod 5 connected to the mandrel-limiting trolley 2 through a flange, and a support rod 5 Threaded connection with the mandrel 6; the main shaft 2-1 of the mandrel stop trolley 2 is connected with the active rotation device 1 through a flange, and the main shaft 2-1 is installed between the shell of the mandrel stop trolley 2 There are bearings 2-2.

[0014] The active rotating device 1 is a hydraulic motor, or a motor-belt, motor-sprocket drive, or a servo motor direct drive.

[0015] Working process of the present invention:

[0016] The wheel 4 of the mandrel stop trolley 2 runs along the guide rail 3 under the constraint of the stop cylinder. Under the rotation of the roll 7, the pipe 8 enters the rolling section for longitudinal rolling, and the mandrel 6 moves forward or backward according to the process requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com