Detent blanking die structure

A blanking die and pawl technology, applied in the field of pawl blanking die structure, can solve problems such as low service life, inability to exit, and inability to produce normally, reducing production costs, facilitating material return, saving labor and processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

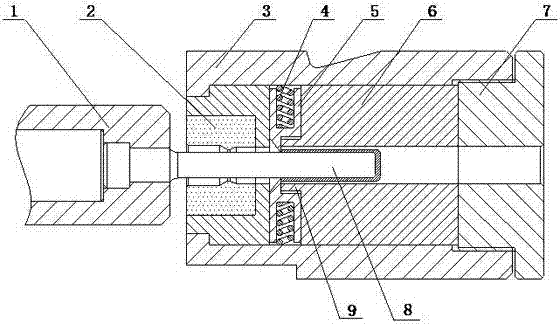

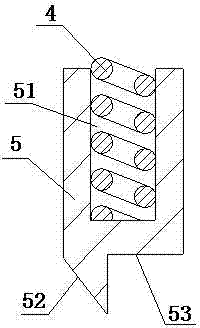

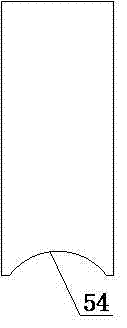

[0017] Such as figure 1 A ratchet blanking die structure is shown, which includes a die 1 and a die. The die includes a mold cover 3, and the inside of the upper part of the die cover 3 is provided with a shrink rod alloy die 2, and the center of the shrink rod alloy die 2 is provided with a mold Cavity, a silk disc 7 is provided at the bottom of the mold case 3, an upper punch rod 8 is provided on the head of the punching die 1, a ratchet seat 6 is provided on the wire disc 7 inside the die case 3, and the wire The center of the disc 7 and the pawl seat 6 is provided with a blanking through hole for the upper punch rod 8 to be inserted and penetrated, and a pawl unit is provided between the pawl seat 6 and the shrink rod alloy mold 2, such as figure 2 and image 3 The shown ratchet unit includes a ratchet 5 and a spring 4 provided between the ratchet 5 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com