High-temperature-resistant glass fiber cloth edge sealing agent and preparation method thereof

The technology of glass fiber cloth and edge sealing agent is applied in the field of materials, which can solve the problems of limiting the application of edge sealing cloth and the high temperature baking conditions of the edge sealing cloth, and achieves the effect of not easy to crack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

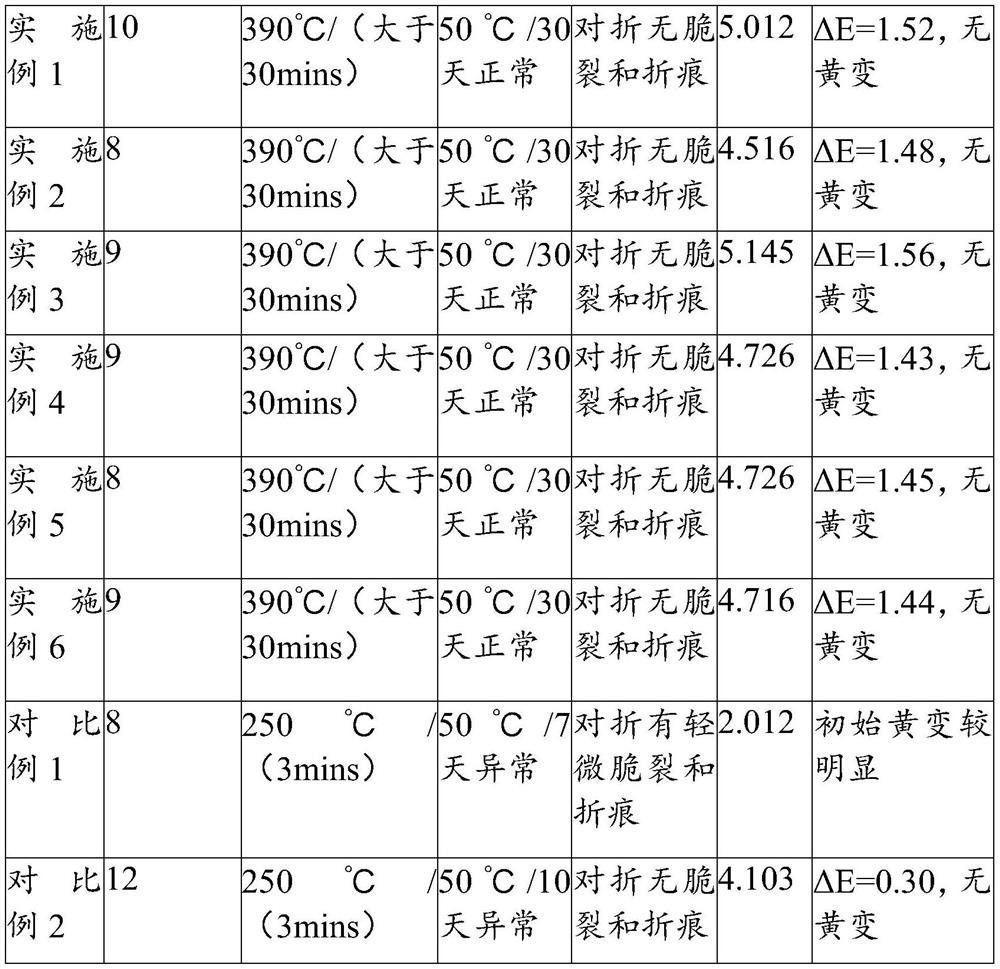

Examples

Embodiment 1

[0029] This embodiment provides a high-temperature-resistant glass fiber cloth edge banding agent, which includes the following raw material components based on 100 g of the total mass: 90 g of fluororesin, 3 g of surfactant, 3 g of silane coupling agent, and 4 g of water.

[0030] Among them, the fluorine resin is: polytetrafluoroethylene emulsion 60g, tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion 20g, perfluoroethylene propylene copolymer emulsion 10g, surfactant is alkyl polyoxyethylene ether , The silane coupling agent is γ-glycidyl etheroxypropyl trimethoxysilane.

[0031] The high temperature resistant glass fiber cloth edge sealing agent of the present embodiment is prepared by the following method:

[0032] Mix γ-glycidyl etheroxypropyltrimethoxysilane and water, stir at a speed of 50 rpm / min at a temperature of 30-45 °C, and stir for 40 mins to obtain the first mixture; Ethylene emulsion, tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer ...

Embodiment 2

[0034] This embodiment provides a high-temperature-resistant glass fiber cloth edge banding agent, which includes the following raw material components based on 100 g of the total mass: 40 g of fluororesin, 3 g of surfactant, 3 g of silane coupling agent, and 54 g of water.

[0035] Among them, the fluorine resin is: polytetrafluoroethylene emulsion 26g, tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion 9g, perfluoroethylene propylene copolymer emulsion 5g, surfactant is alkyl polyoxyethylene ether , The silane coupling agent is γ-glycidyl etheroxypropyl triethoxysilane.

[0036] The high temperature resistant glass fiber cloth edge sealing agent of the present embodiment is prepared by the following method:

[0037] Mix γ-glycidyl etheroxypropyltriethoxysilane and water, stir at a speed of 80rpm / min at a temperature of 30-45°C, and stir for 35mins to prepare the first mixture; Mix fluoroethylene emulsion, tetrafluoroethylene-perfluoroalkoxy vinyl ether copol...

Embodiment 3

[0039] This embodiment provides a high-temperature-resistant glass fiber cloth edge banding agent, which includes the following raw material components based on 100 g of the total mass: 90 g of fluororesin, 3 g of surfactant, 3 g of silane coupling agent, and 4 g of water.

[0040] Among them, the fluorine resin is: polytetrafluoroethylene emulsion 60g, tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer emulsion 20g, perfluoroethylene propylene copolymer emulsion 10g, surfactant is nonylphenol polyoxyethylene Ether, silane coupling agent is phenyltriethoxysilane.

[0041] The high temperature resistant glass fiber cloth edge sealing agent of the present embodiment is prepared by the following method:

[0042] Mix phenyltriethoxysilane and water, stir at a speed of 50rpm / min at a temperature of 30-45°C, and stir for 30mins to obtain the first mixture; mix polytetrafluoroethylene emulsion, tetrafluoroethylene Mix ethylene-perfluoroalkoxy vinyl ether copolymer emulsion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com