Multi-model parts universal transporter

A transport vehicle and multi-model technology, applied in the direction of launching/dragging transmission devices, etc., can solve the problems of lack of versatility of support tooling and large working space, and achieve the effect of reducing costs and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the multi-type component universal transport vehicle of the present invention will be described below in conjunction with the accompanying drawings.

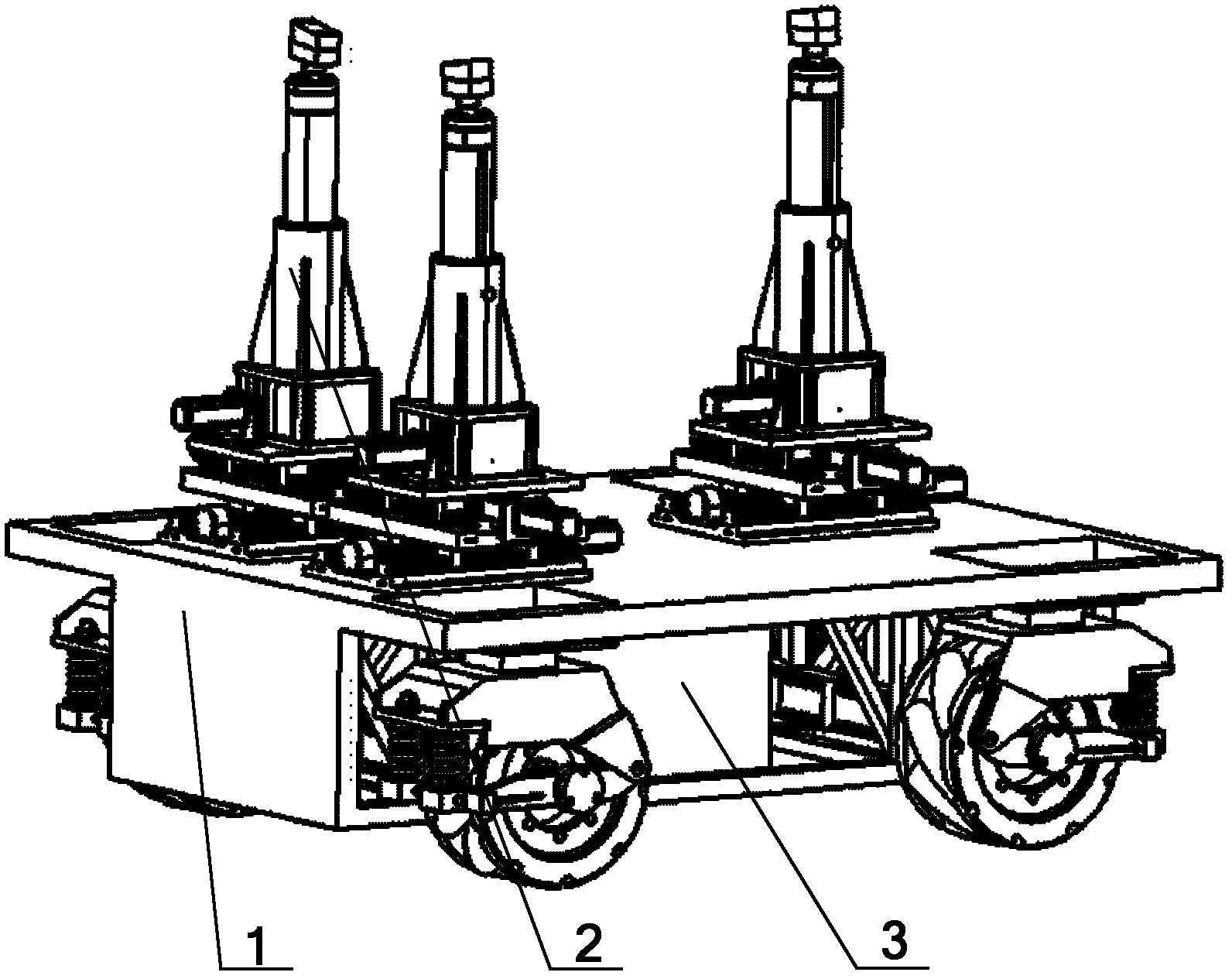

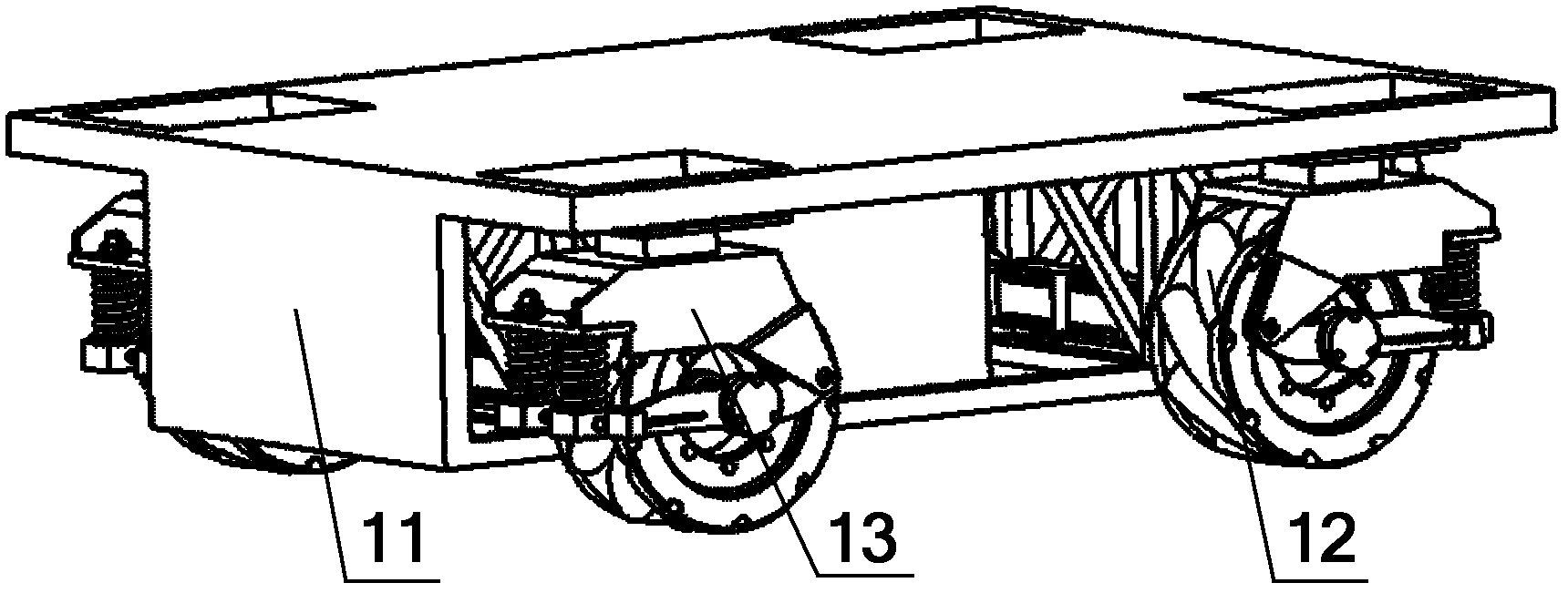

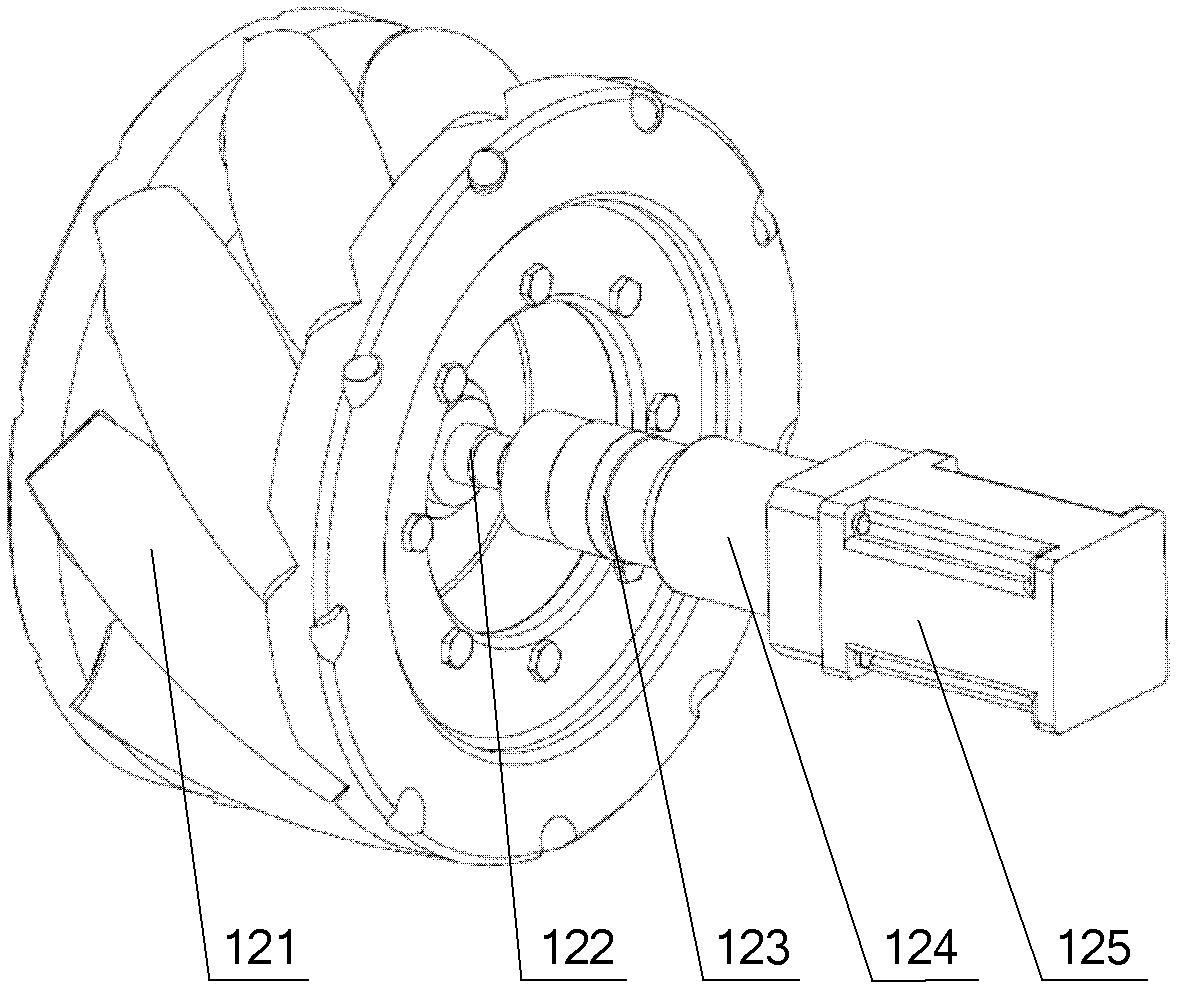

[0016] refer to figure 1 . The present invention proposes a multi-model parts universal transport vehicle, which mainly includes an omnidirectional moving mechanism 1 , a flexible support system 2 and a control device 3 . The omnidirectional mobile mechanism 1 is made up of a vehicle body 11 and four self-driven omnidirectional wheels 12 mounted on the vehicle body 11 . Omni-directional wheels 12 distributed in a rectangle are arranged according to the principle of the golden section in terms of the ratio of the long and short sides of the rectangle. The flexible supporting device 2 is distributed on the vehicle body platform in a polygonal shape, and is composed of a cross moving platform 21 and a lifting mechanism 22 with a flexible process joint 23 . The flexible supporting device 2 install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com