Air pressure control system and method for air jet loom

An air pressure control and air jet loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of high price of electronically controlled proportional valves and restrict promotion, meet the requirements of air pressure value stability and reduce price costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

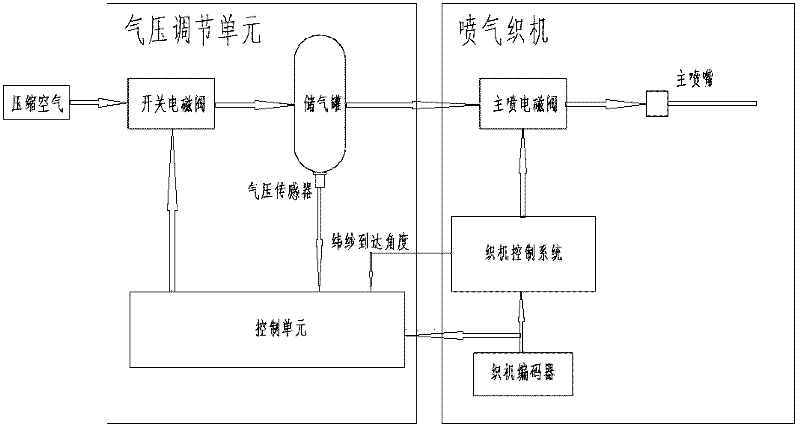

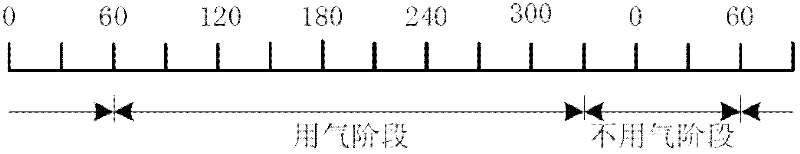

[0020] Such as figure 1 As shown, the air pressure control system of the air-jet loom of the present invention includes an air storage tank, a switch solenoid valve located at the compressed air inlet of the air storage tank, an air pressure sensor located in the air storage tank, respectively connected to the switch electromagnetic The control unit connected to the valve, the air pressure sensor and the loom control system, and the loom encoder used to collect the state of the loom; the control unit is used for signal acquisition and calculation, and controls the opening and closing of the switch solenoid valve according to the calculation result; The loom encoder is respectively connected with the loom control system and the control unit.

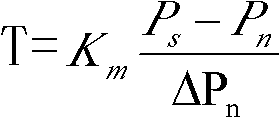

[0021] The air storage tank is used to store compressed air that requires a stable air pressure value. The switch solenoid valve is controlled by the control unit to open and close, and the air bag is inflated when it is opened. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com