High reliability bearingless planetary transmission

A planetary transmission, bearingless technology, used in transmissions, transmission parts, gear transmissions, etc., can solve problems such as difficulty in meeting strength requirements, and achieve high strength, guaranteed strength, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

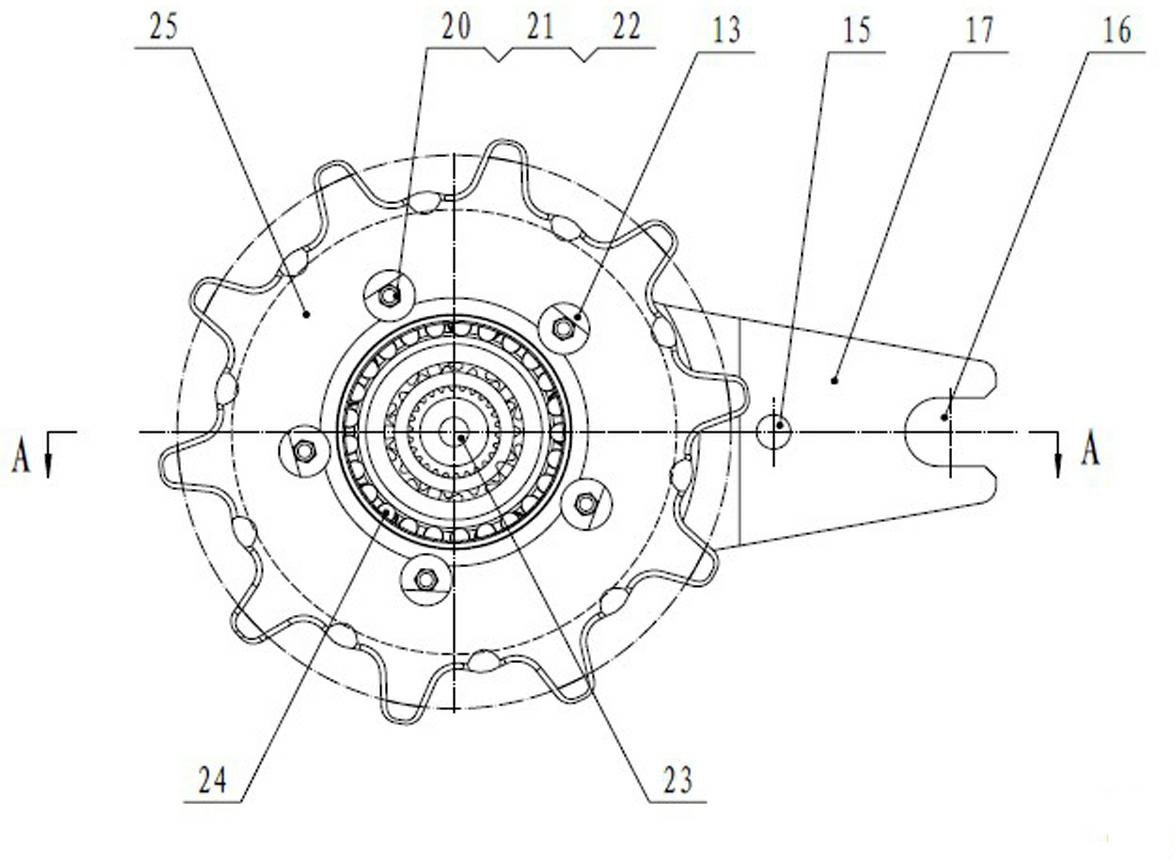

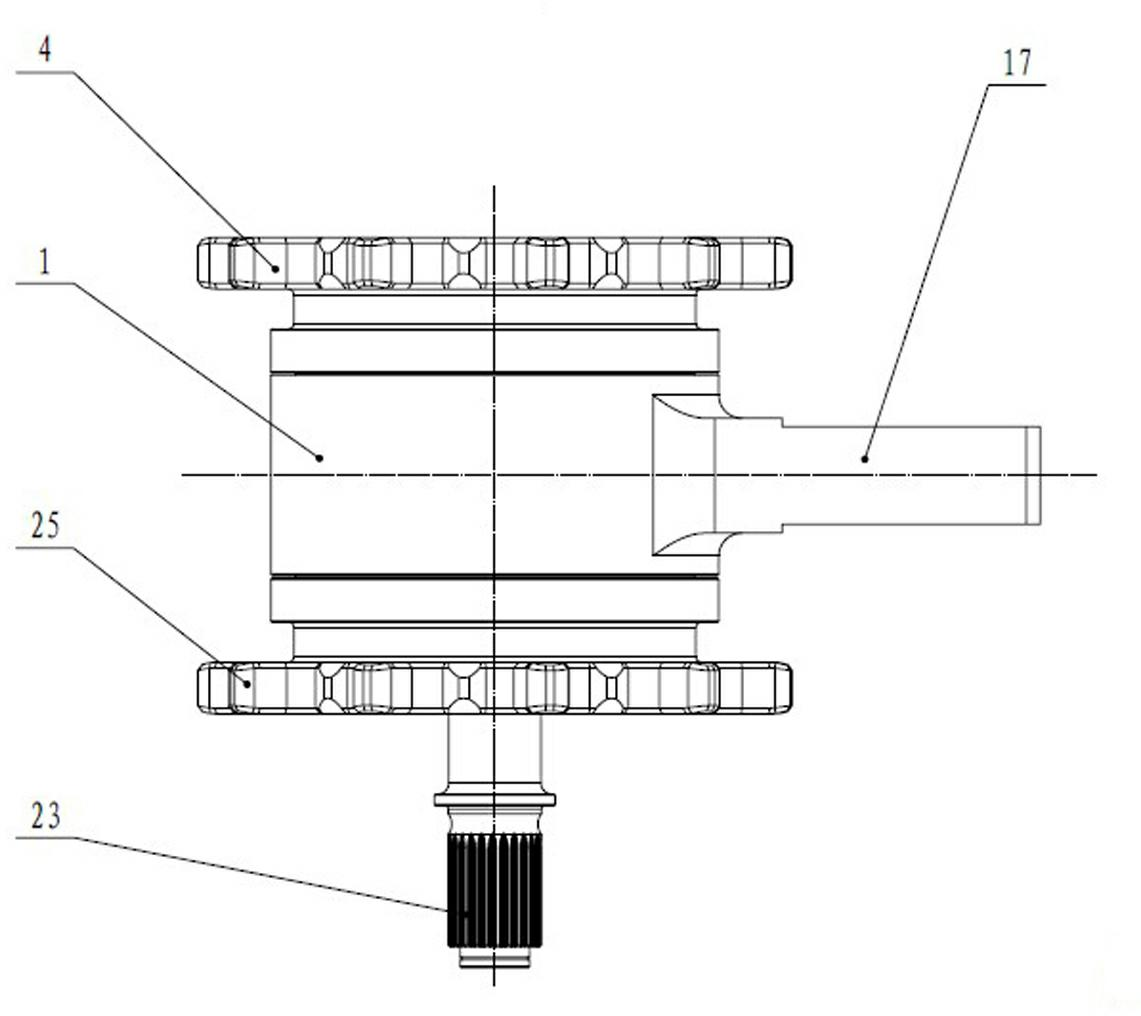

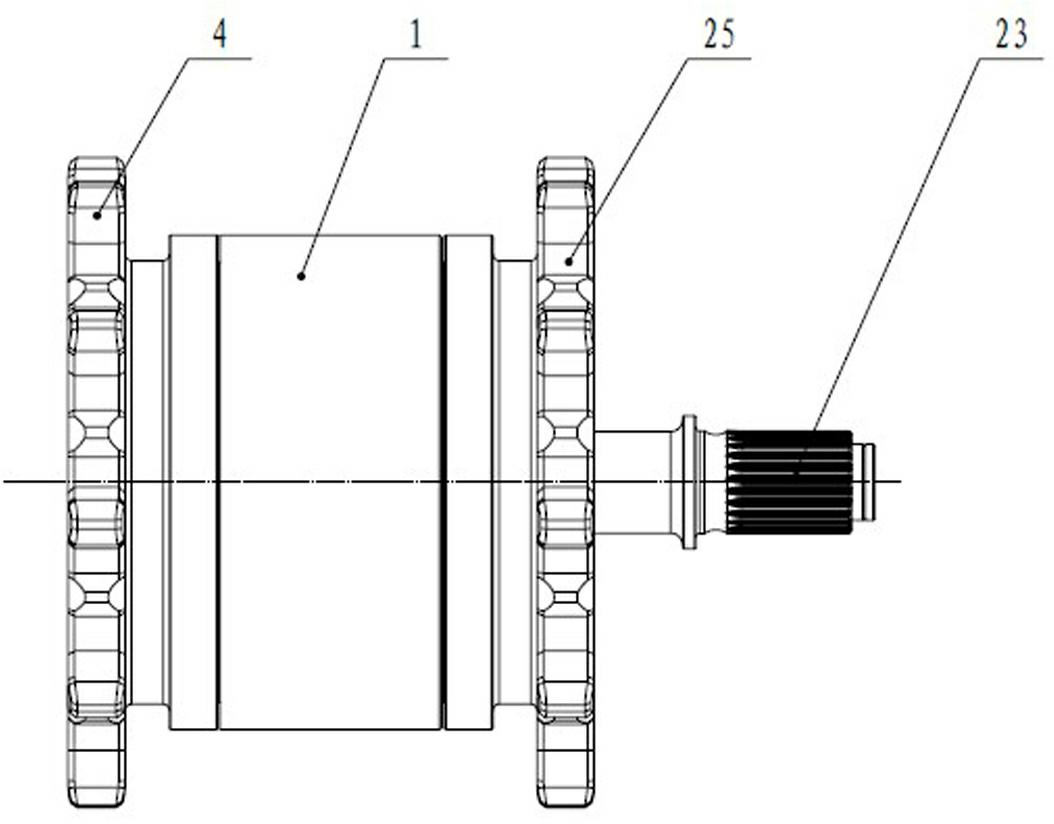

[0020] The present invention will be further described below in conjunction with the accompanying drawings. In the embodiment, the driven part is a sprocket as an example.

[0021] figure 1 , 2 , shown in 3, is the overall structure diagram of the present invention, 5 planetary gears 7, planetary shaft 6 that odd numbers are arranged outside sun gear 23, planetary gear 7 is installed on the planetary shaft 6, and planetary gear 7, planetary shaft 6 are installed on Inside the planetary carrier 18, the planetary carrier 18 is connected with the sprocket I4 and the sprocket II25 through the transmission pin I14, the transmission pin II19, the stud I10, the stud II20, the nut I11, the nut II21, the washer I12, and the washer II22; the inner gear ring 1 The right outside is the inner ring gear arm 17, the process hole 15, and the positioning groove 16. The positioning groove 16 fixes the inner ring gear 1. The sprocket I4 and the sprocket II25 are fixed on the hub of the frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com