A system for producing steam by using the waste heat of coke oven heating exhaust gas

A technology for heating exhaust gas and producing steam, which is used in steam generation methods using heat carriers, steam boilers, steam generation, etc. good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

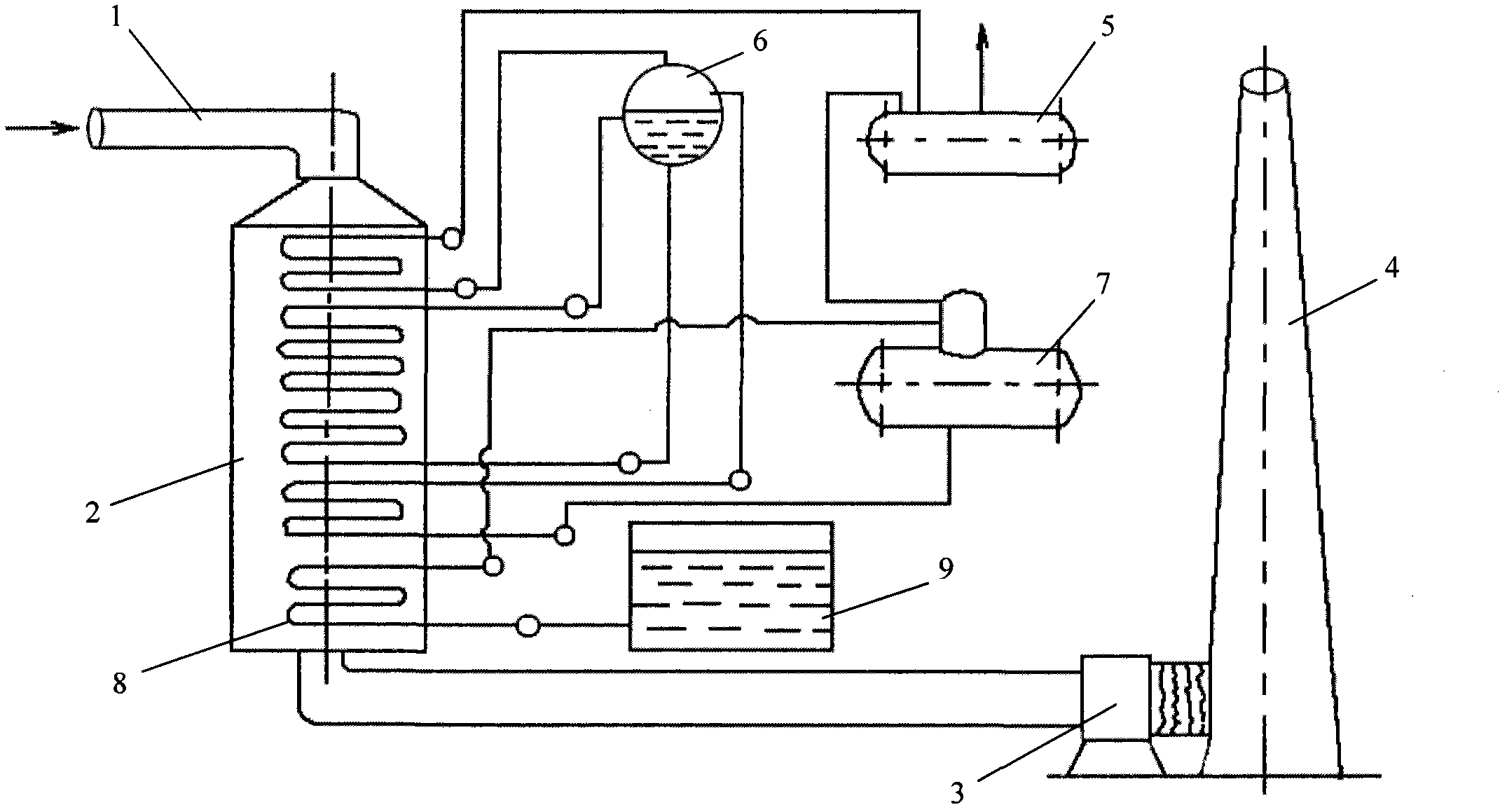

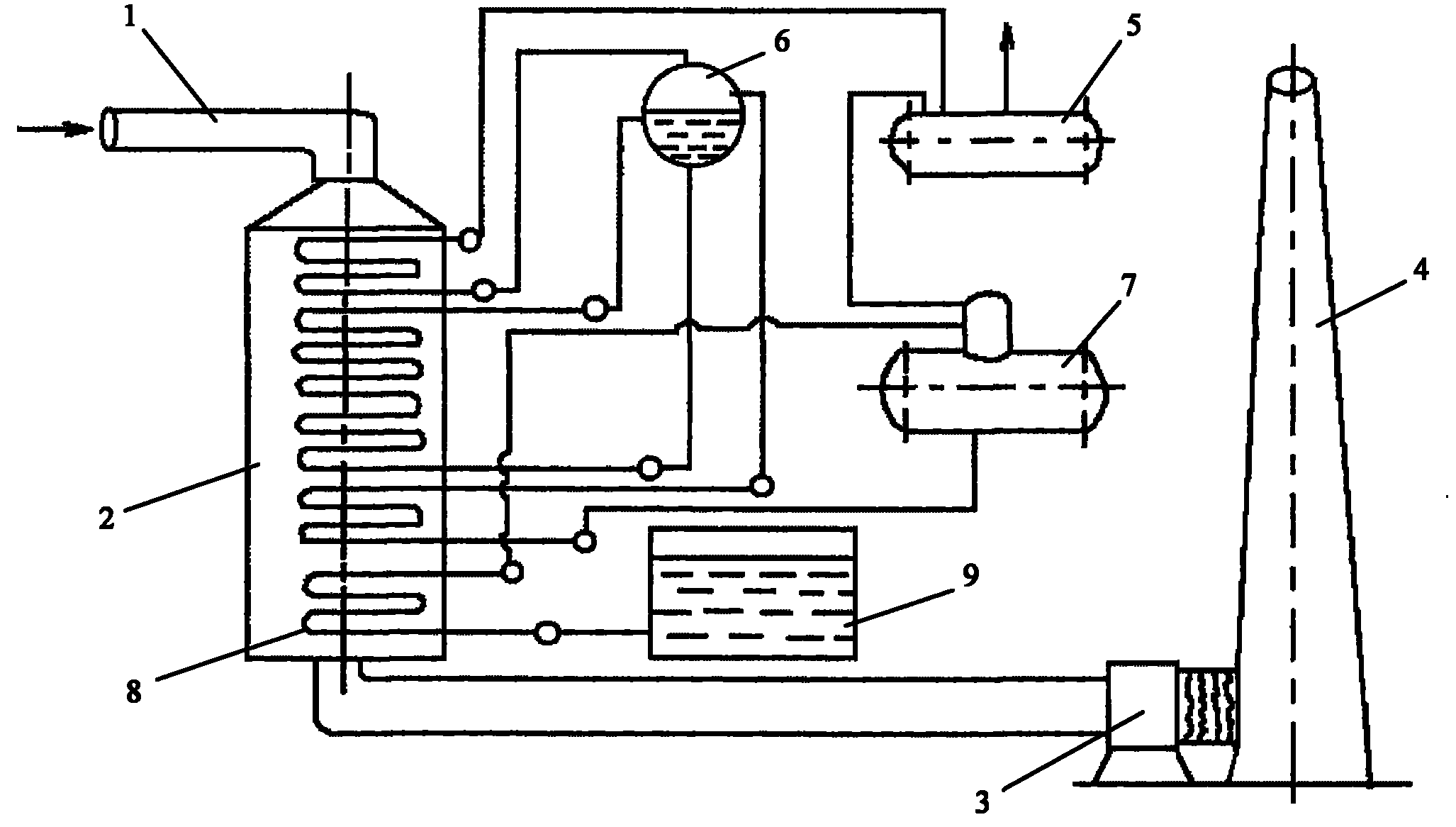

[0016] The system principle of the present invention is as figure 1 As shown, it includes a waste heat boiler 2 whose upper end is connected to the coke oven exhaust gas flue 1. The lower end of the waste heat boiler 2 is connected to the coke oven chimney 4 through an induced draft fan 3. The waste heat boiler 2 is provided with superheaters in sequence from top to bottom. 5. Evaporator 6, economizer 7, cold water preheater 8; the inlet header of cold water preheater 8 is connected to softened water tank 9, the outlet header is connected to economizer 7, and the outlet header of economizer 7 is connected to The evaporator 6 is connected, and the steam outlet of the evaporator 6 is connected with the inlet header of the superheater 5 .

[0017] Those skilled in the art should understand that, figure 1 The shown is only a schematic diagram, and does ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap