Chimney paste type anti-corrosion layer and construction method

A construction method and anti-corrosion layer technology, which is applied in the direction of combustion method, combustion product treatment, exhaust gas exhaust device, etc., to achieve the effect of ensuring the quality of pasting, preventing falling off, and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

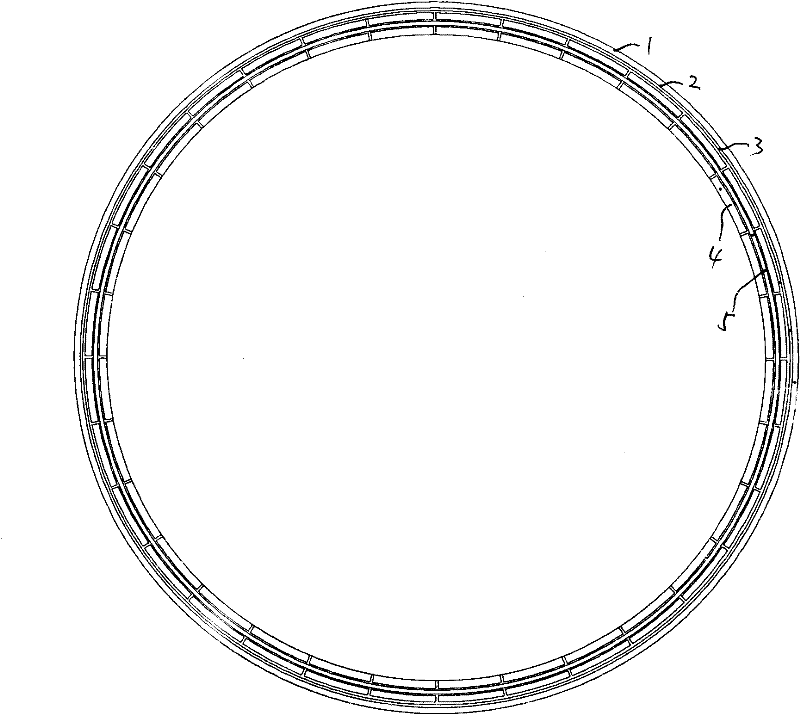

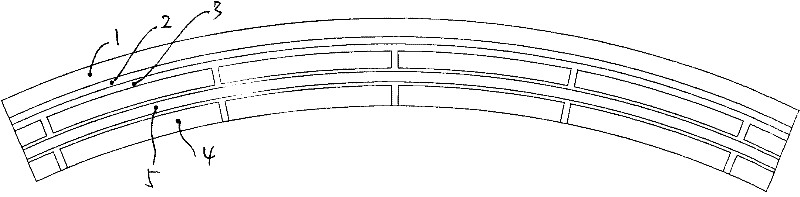

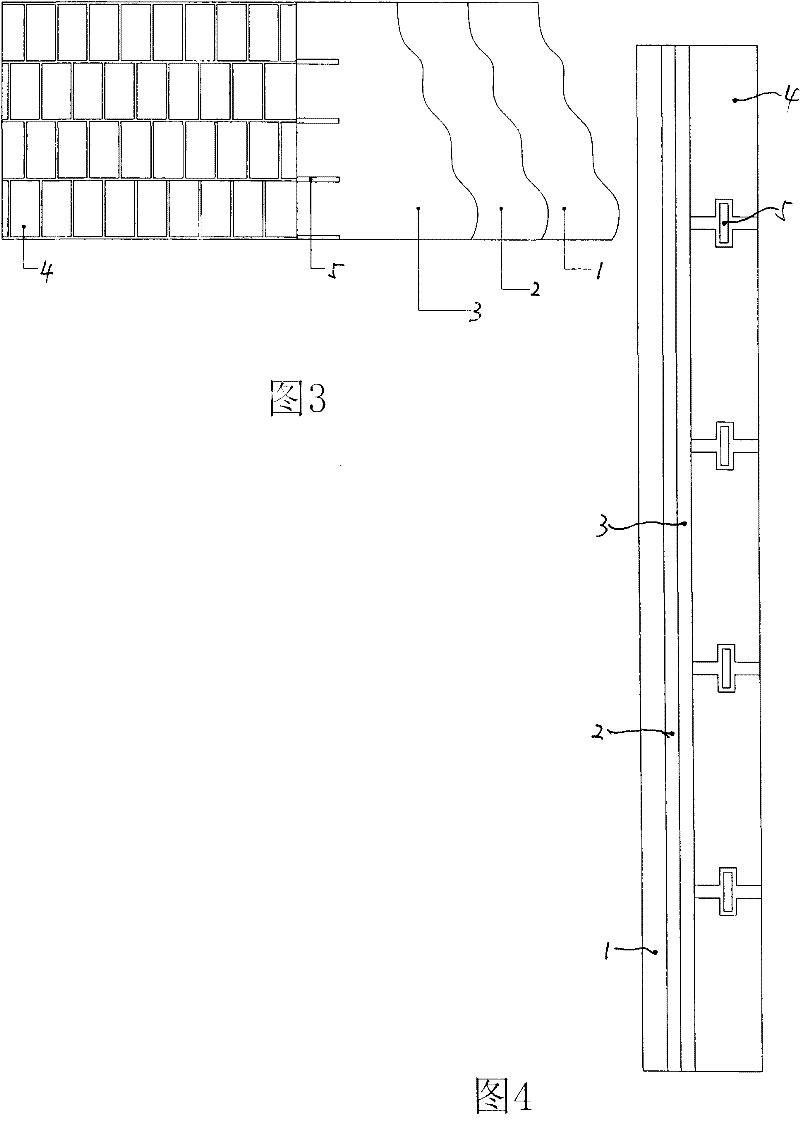

[0015] Embodiment: Referring to the accompanying drawings, first, groove the upper and lower end surfaces of the pasted foam glass bricks (or require to provide upper and lower end surface grooved bricks), first apply the anti-corrosion primer 2 on the inner surface of the chimney steel inner cylinder 1, and then apply the anti-corrosion primer 2 on the primer surface Scrape the silicone rubber 3, and also apply silicone rubber on the adhesive surface of the foam glass brick 4, press it on the inner surface of the chimney, paste it piece by piece into a circle, and bend the heat-resistant and anti-corrosion plastic strip or stainless steel strip whose height is greater than the depth of the groove. Put it in the groove on the top surface of the pasting brick, apply the adhesive, and continue pasting the upper anti-corrosion brick, and so on until the pasting is completed.

[0016] The pasting structure and method of the present invention can be used not only for newly-built chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com