A solar concrete heat storage device for heat energy compensation of heat pumps

A heat storage device and concrete technology, applied in heat storage equipment, energy storage, indirect heat exchangers, etc., can solve the problems of relatively low heat storage density, high cost, and many parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

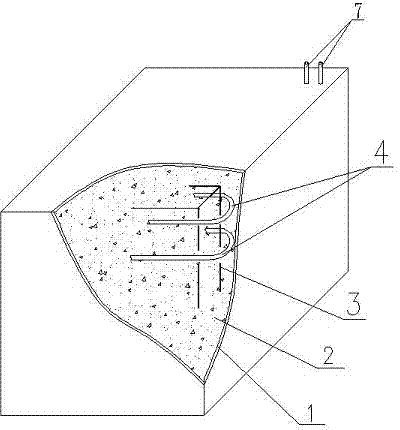

[0025] Example 1, such as figure 1 As shown, a solar energy concrete thermal storage device for heat pump thermal energy compensation includes concrete 2, the concrete 2 is provided with a steel frame 3, and the steel frame 3 is wound with D20 transmission material made of PE-RT material. The heat pipe 4 is provided with an insulating layer 1 made of asbestos material outside the concrete 2 .

[0026] Both ends of the heat transfer pipe 4 have pipe joints 7 respectively, and the pipe joints 7 are arranged outside the concrete 2 .

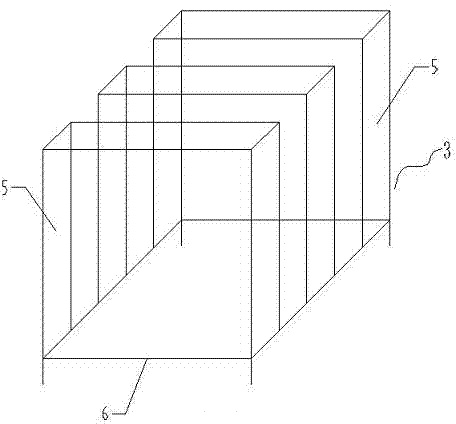

[0027] Such as figure 2 As shown, the reinforcement frame 3 includes three reinforcement cages 5 welded with M8 reinforcement and a reinforcement base 6 welded with M8 reinforcement, and the distance between the reinforcement cages 5 is 150 mm.

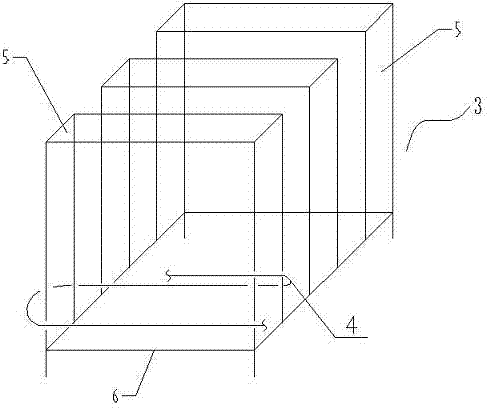

[0028] Such as image 3 As shown, the heat transfer tubes 4 are respectively wound on three reinforcement cages 5, with 8 turns evenly distributed on each reinforcement cage 5, and the heat transfer t...

Embodiment 2

[0035] Such as figure 1 As shown, a solar energy concrete thermal storage device for heat pump thermal energy compensation includes concrete 2, the concrete 2 is provided with a steel frame 3, and the steel frame 3 is wound with D20 transmission material made of PE-RT material. heat pipe4.

[0036] An insulating layer 1 made of asbestos material is provided outside the concrete 2 .

[0037] Both ends of the heat transfer pipe 4 have pipe joints 7 respectively, and the pipe joints 7 are arranged outside the concrete 2 .

[0038] Such as figure 2 As shown, the reinforcement frame 3 includes three reinforcement cages 5 welded with M8 reinforcement and a reinforcement base 6 welded with M8 reinforcement, and the distance between the reinforcement cages 5 is 200 mm.

[0039] Such as image 3 As shown, the heat transfer tubes 4 are respectively wound on three reinforcement cages 5, with 6 turns evenly distributed on each reinforcement cage 5, and the heat transfer tubes 4 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap