A short-focus, ultra-wide-angle, high-definition LCD projector lens with a spherical surface

An ultra-wide-angle, projector technology, applied in the field of projection objective lenses, can solve the problems of short projection distance, high cost, difficult aspheric lens processing, etc., and achieve the effects of convenient installation, convenient processing, and low processing cost.

Inactive Publication Date: 2011-12-21

苏州轰天炮光电科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

3LCD projectors currently use two types of projection lenses: the first one is made of about ten pieces of various spherical lenses, which are characterized by: mature production (spherical lenses are easy to grind and process), long projection distance, about 3M (At this time, the diagonal length of the projection screen is about 80 inches); the second is to change one or two of the spherical lenses into aspheric lenses on the basis of the first one, so as to achieve a short projection distance (about 1M), and the screen The effect of constant size (that is, short-focus, ultra-wide-angle performance), is characterized by: the aspheric lens used in the lens that can reach a certain resolution is difficult to process, and the cost is extremely high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

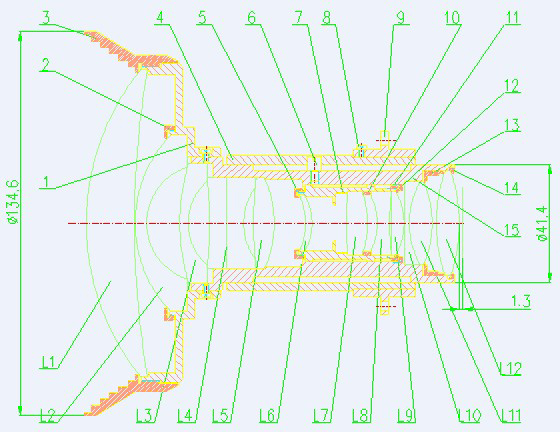

[0012] The lens of the present invention is installed in front of the liquid crystal panel, and a color-combining prism is placed in the middle, the length of the color-combining prism is 26mm, the air gap between the color-combining prism and the last lens of the lens is 6mm, and the air gap between the color-combining prism and the liquid crystal panel is 4mm .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

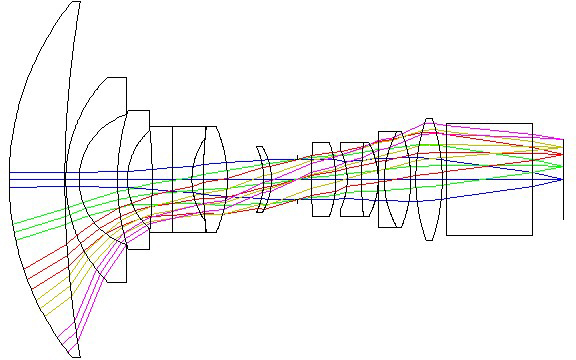

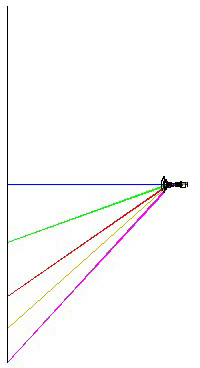

The invention relates to a projection objective lens for a three-piece liquid crystal front-projection projector. The invention adopts the projection objective lens combined with 12 spherical lenses, and the glass grinding process is convenient and the processing cost is low. The present invention meets the requirements of full high-definition, and is suitable for a resolution of 1920*1080, and an image aspect ratio of 16:9. The present invention has a 1M projection of 91 inches, an image square eccentricity of 0:10, conforms to short-focus, super-wide-angle performance, and is easy to install.

Description

technical field [0001] The invention relates to a projection objective lens (hereinafter referred to as a lens) for a three-chip liquid crystal (hereinafter referred to as 3LCD) front-projection projector. The invention has the characteristics of simple manufacture, low cost, short projection distance, large projection screen, and high resolution. Background technique [0002] According to the classification of image display devices, the image display technology of front projection projectors is mainly divided into three major technical fields: 3LCD, DLP, and LCOS. 3LCD projectors currently use two types of projection lenses: the first one is made of about ten pieces of various spherical lenses, which are characterized by: mature production (spherical lenses are easy to grind and process), long projection distance, about 3M (At this time, the diagonal length of the projection screen is about 80 inches); the second is to change one or two of the spherical lenses into aspheric...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G02B13/06G02B13/00G02B3/00G02B7/02

Inventor 胡先君徐广清

Owner 苏州轰天炮光电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap