A Reconfigurable Assembly System Modeling Method Based on Agent-based Timed Colored Petri Nets

A technology of assembly system and modeling method, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of applicability and system timeliness, difficult to describe and analyze well, disaster of dimensionality, difficult to describe Issues such as reconstruction of the overall picture of the manufacturing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

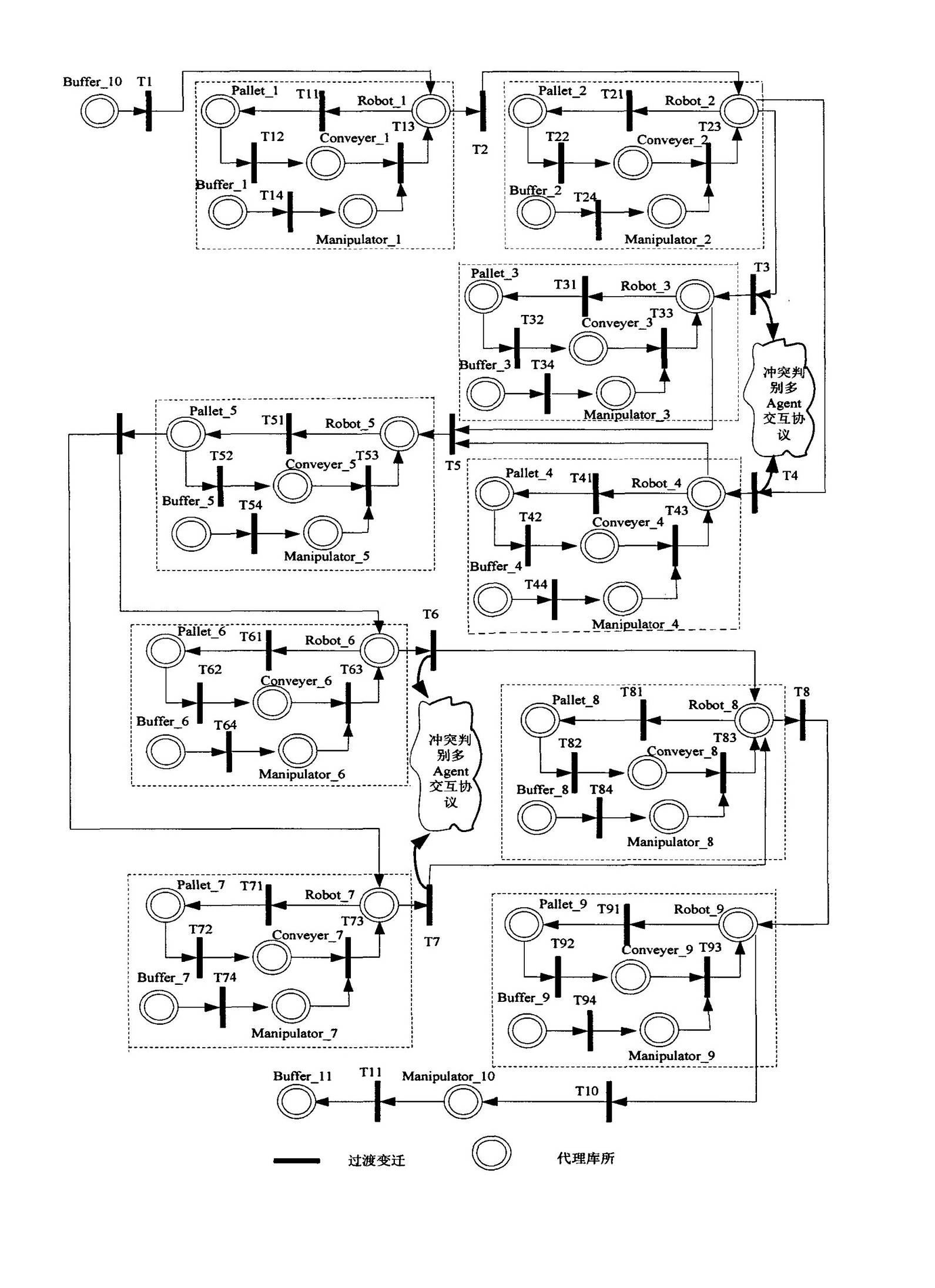

[0043] Taking a reconfigurable assembly line of a special vehicle manufacturing enterprise as an example, the assembly line mainly completes the assembly of shafts, gears, disc sleeves, torque converters, and boxes of special vehicle transmissions. Although the models of the transmission are different, the number of assembly parts is basically the same and the assembly sequence is the same, so the same assembly line can be used. The assembly process of the transmission is mainly completed by an assembly robot. The specific solution steps are:

[0044] Step 1: Assembly resource model construction.

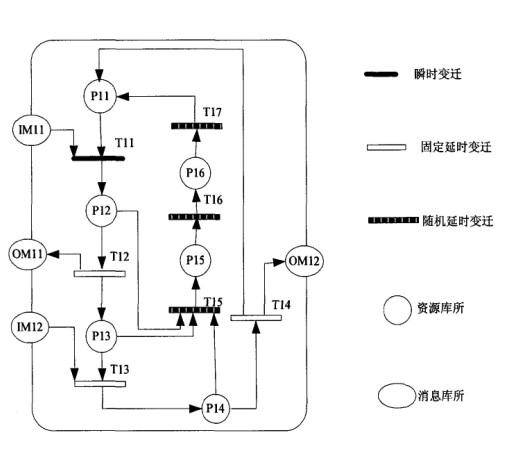

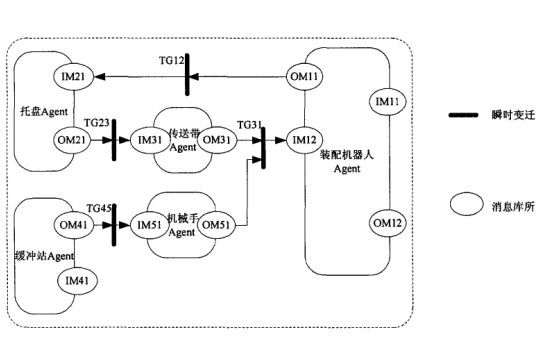

[0045] According to the operating status of the assembly unit, the state transition diagram (State Transition Diagram, STD) of the assembly unit is obtained, and then STD is converted into ATCPN on this basis. Each type of Agent subnet represents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com