High-reliability constant voltage mode semiconductor laser driver with continuously adjustable output light power

A technology of laser driver and constant voltage mode, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of amplifier heating, slow response of current limiting protection, etc., achieve efficient protection, solve severe heating, and fast response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

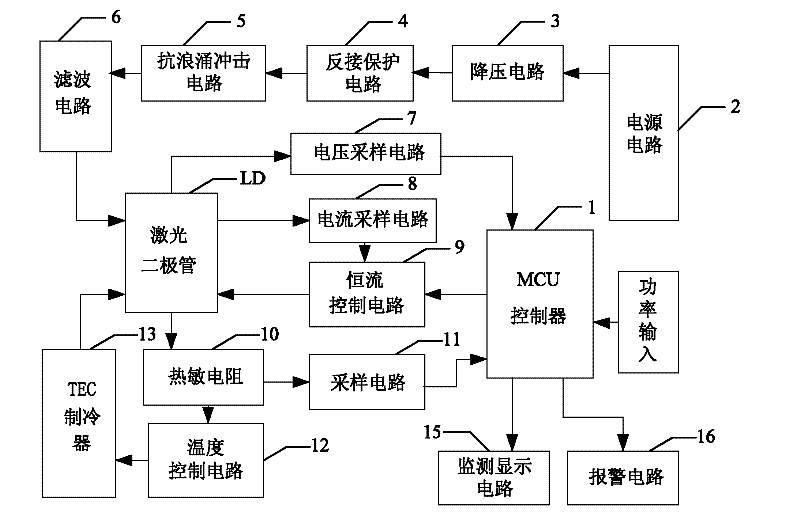

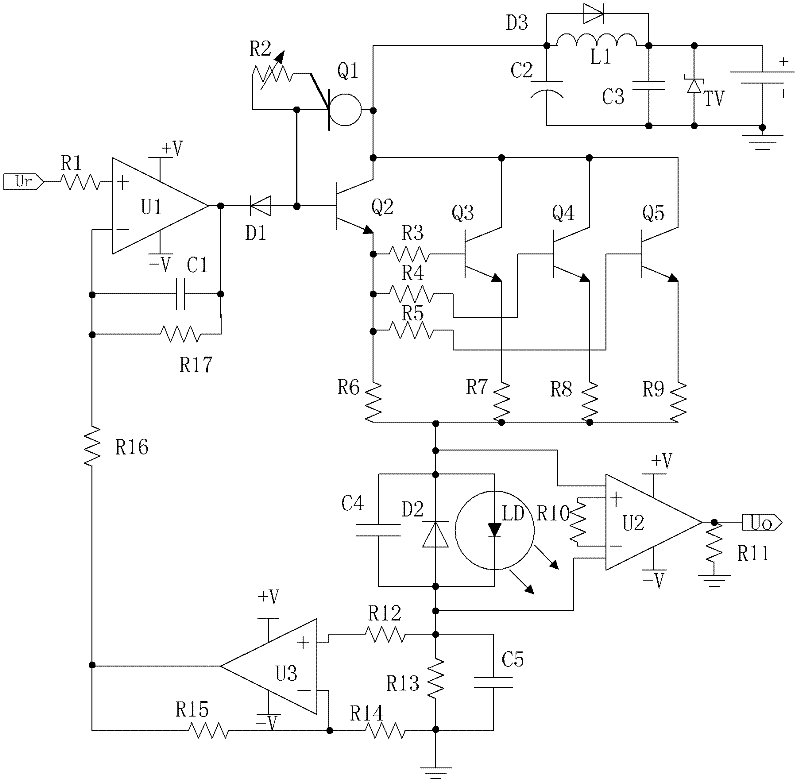

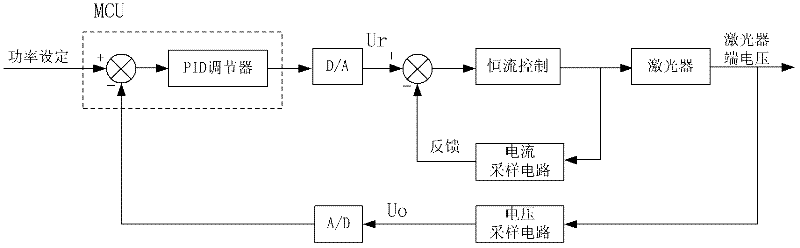

[0018] Specific implementation mode 1. Combination figure 1 Describe this specific implementation mode, a highly reliable constant voltage mode semiconductor laser driver with continuously adjustable output optical power, which includes an MCU controller 1, a power supply circuit 2, a step-down circuit 3, a reverse connection protection circuit 4, and an anti-surge impact circuit 5 , filter circuit 6, voltage sampling circuit 7, current sampling circuit 8, constant current control circuit 9, thermistor 10, sampling circuit 11, temperature control circuit 12, TEC refrigerator 13 and laser diode LD;

[0019] The power signal output end of the power supply circuit 2 is connected to the power signal input end of the step-down circuit 3, the power signal output end of the step-down circuit 3 is connected to the signal input end of the reverse connection protection circuit 4, and the signal output end of the reverse connection protection circuit 4 It is connected with the signal inp...

specific Embodiment approach 2

[0038] Embodiment 2. The difference between this embodiment and the highly reliable constant voltage mode semiconductor laser driver with continuously adjustable output optical power described in Embodiment 1 is that it also includes a monitoring and display circuit 15. The monitoring and display circuit 15 The temperature signal input end of the MCU controller 1 is connected with the temperature signal output end.

[0039] This embodiment can monitor and display the current operating parameters of the system.

specific Embodiment approach 3

[0040] Embodiment 3. The difference between this embodiment and the highly reliable constant voltage mode semiconductor laser driver with continuously adjustable output optical power described in Embodiment 1 is that it also includes an alarm circuit 16, and the alarm circuit 16 The signal input end is connected with the alarm signal output end of the MCU controller 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com