Three-phase communal compact solid insulation high voltage AC vacuum switchgear

A solid insulation, high-voltage AC technology, applied in high-voltage/high-current switches, high-voltage air circuit breakers, electric switches, etc., can solve the problems of not meeting user requirements, large equipment footprint, and high raw material consumption, so as to save raw materials , Reduce the equipment footprint, and the effect of large creeping distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

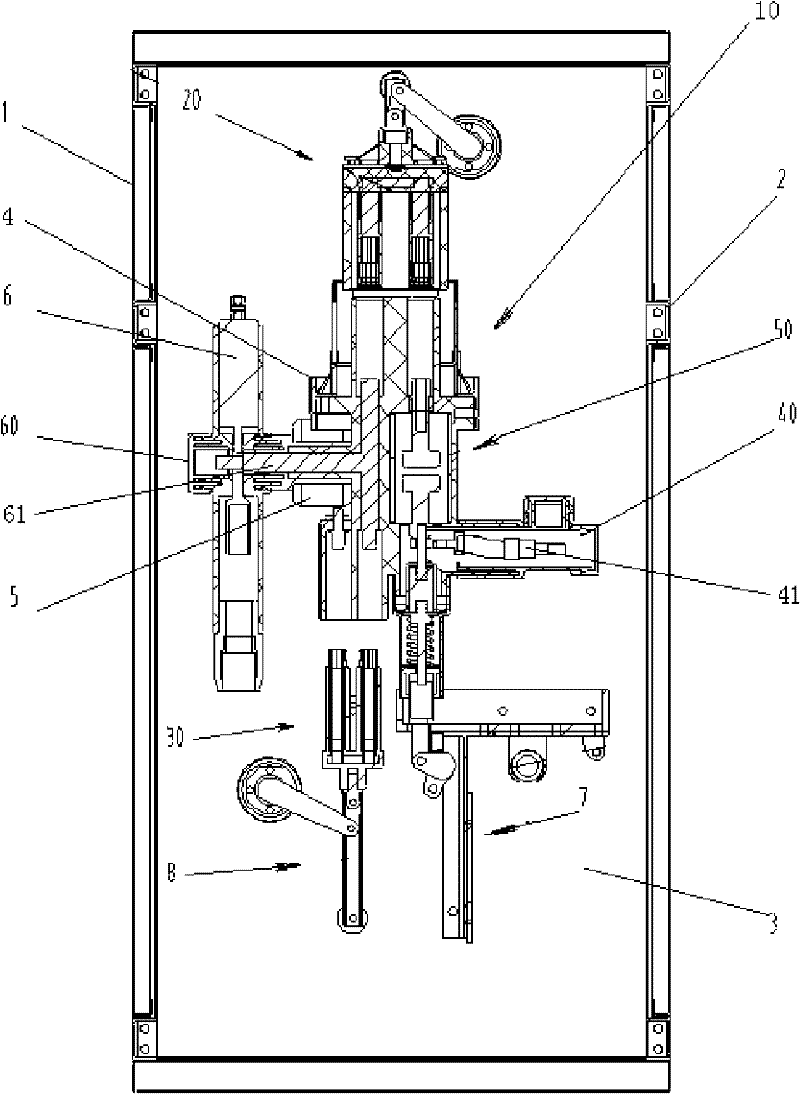

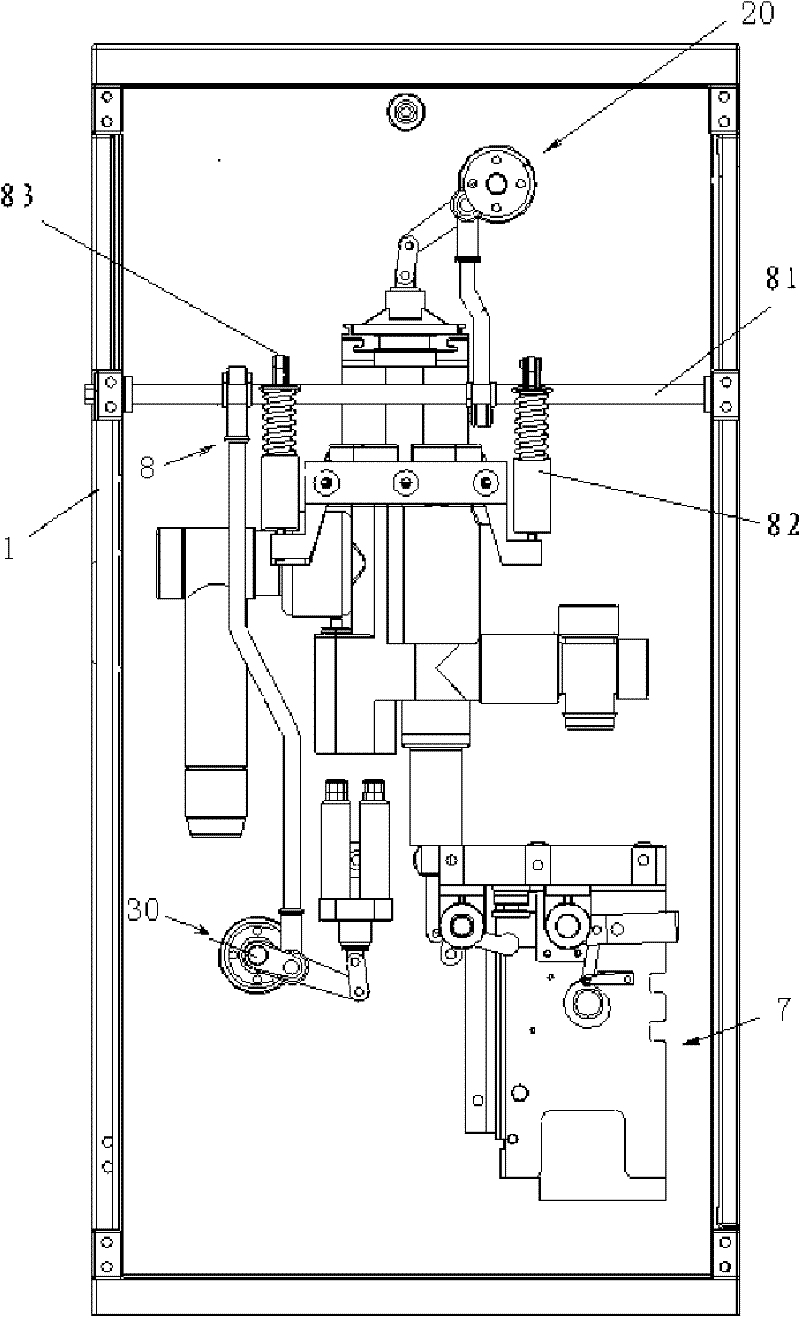

[0021] refer to figure 1 , the three-phase communal compact solid insulated high-voltage AC vacuum switchgear of the present invention includes a box body 1, a built-in isolating switch 20, a vacuum circuit breaker 50, a grounding switch 30, a left cable inlet and outlet terminal 61, a right cable inlet and outlet terminal 41 and an operating mechanism. The operating mechanism includes a spring energy storage operating mechanism 7 and a locking type isolating switch and a manual operating mechanism 8 of the grounding switch.

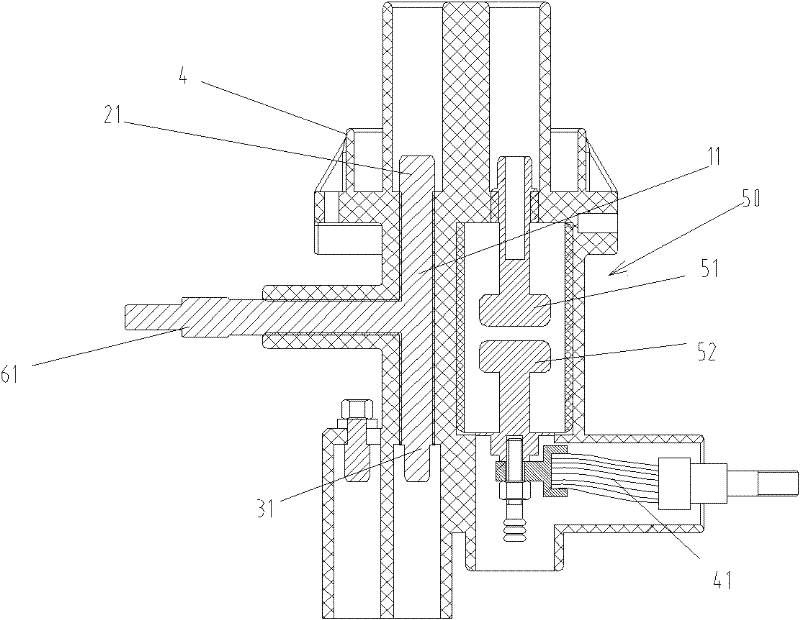

[0022] The box body 1 is provided with a frame 2, and the frame 2 is installed on the side plate 3 of the box body 1. An insulating base 10 is installed on the frame 2 through the mounting bracket 4 . to combine image 3 and Figure 4 , the static contact 21 of the isolating switch 20 , the vacuum circuit breaker 50 , the static contact 31 of the grounding switch 30 , the right cable entry and exit terminal 41 and the left cable entry and exit termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com