Iron carbon micro-electrolysis device

A technology of iron-carbon micro-electrolysis and housing, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of prolonging the use time, reducing costs, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

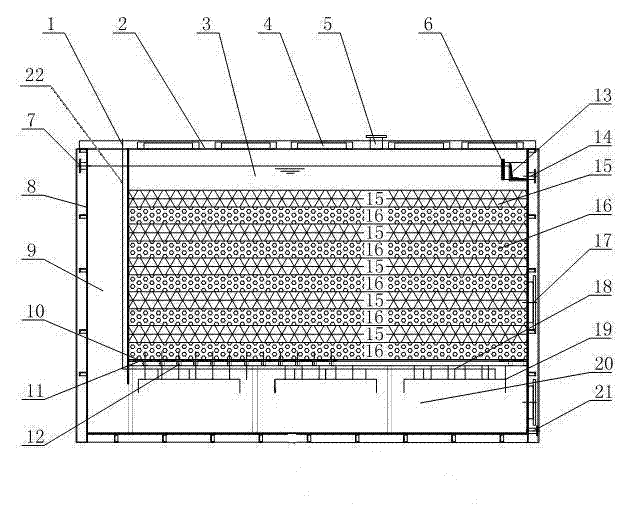

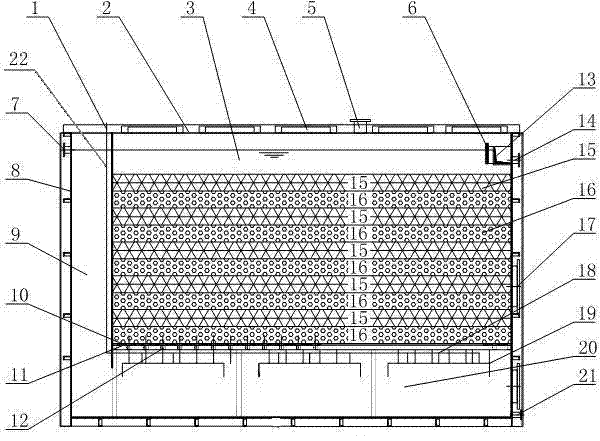

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the iron-carbon micro-electrolysis device comprises a housing 8, a water inlet 7 is set on the left side of the upper wall of the housing 8, a water outlet 14 is arranged on the right side of the upper wall of the housing 8, and a water outlet weir is arranged at the front end of the water outlet 14 13.

[0020] The area on the left side of the housing 8 close to the water inlet 7 is the water inlet area 9, the part of the lower part of the housing 8 connected to the water inlet area 9 is the aeration area 20, and the middle part of the housing 8 is located above the aeration area 20. Filling areas 15, 16, the upper part of the housing 8 above the filling areas 15, 16 is the water outlet area 3, wherein between the water inlet area 9 and the filling areas 15, 16, and between the water inlet area 9 and the water outlet area 3 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com