Pre-assembly processing method for dry quenching chamber outlet arch used in coke dry quenching process

A processing method, CDQ technology, which is applied in coke oven, petroleum industry, coke cooling, etc., can solve the problems that the size cannot be carefully controlled, the method is complicated, and the cost is high, and it is not easy to collapse or deform, and the overall performance is good. The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

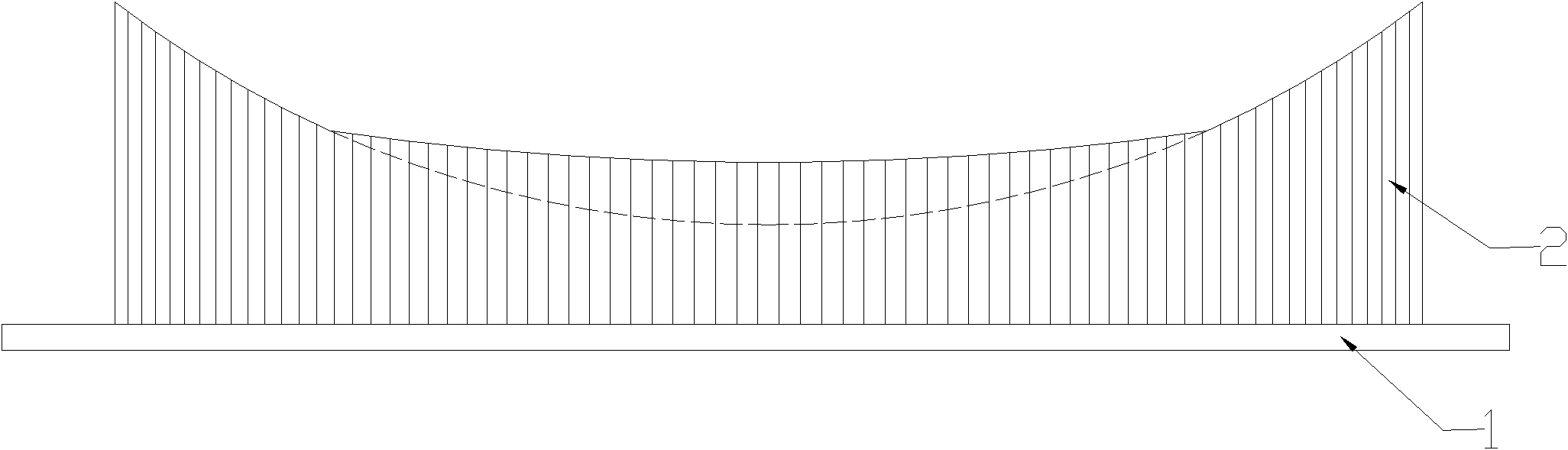

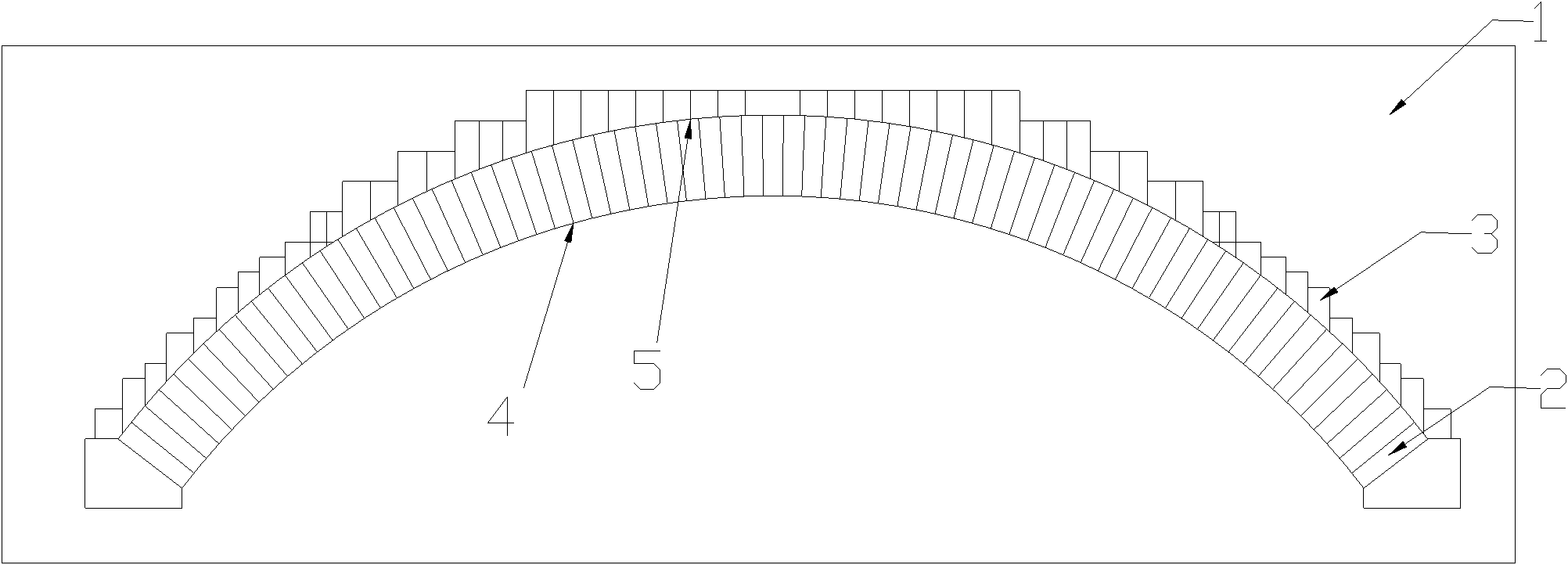

[0021] The arch at the exit of the CDQ chamber needs to be pre-processed and pre-assembled before delivery. The arch at the exit of the CDQ chamber is located on the outer wall of the CDQ furnace and is in the shape of an arch bridge. It must conform to the arc of the outer wall of the CDQ oven. , but also to meet the arc span of the annular air duct gas flow to the primary dust collector. The arch at the exit of the CDQ chamber consists of upper and lower layers. The first layer is composed of mullite bricks, and the second layer is a layer of staggered bricks connecting the large wall.

[0022] Such as figure 1 and figure 2 as shown,

[0023] Prepare a platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com