Fine water mist fire extinguishing system and fire extinguishing method in railway tunnel

A fine water mist technology in tunnels, applied in earthwork drilling, fire prevention, safety devices, etc., can solve problems such as positioning, fire prevention, and inability to fully cover the train body, achieving system security, safe and convenient use, and Run Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

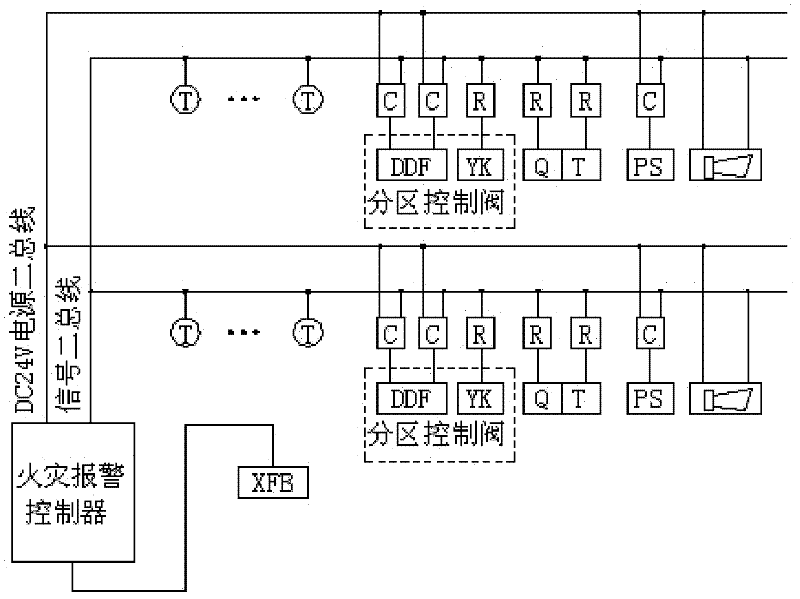

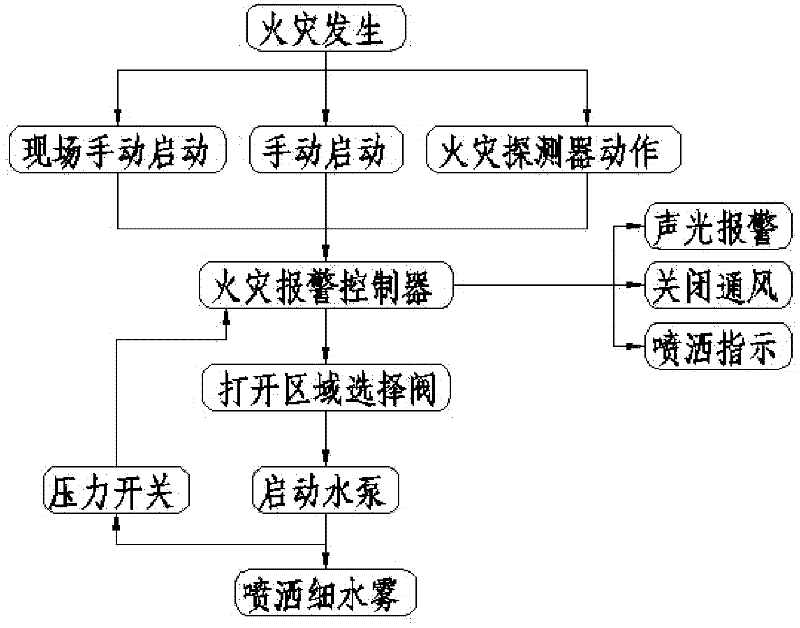

[0020] Such as figure 1 , figure 2 shown. figure 1 Among them, T is the image type fire detector, C is the output module, R is the input module, DDF is the electric valve, YK is the pressure switch, Q / T is the start / stop button, PS is the spraying instruction, It is sound and light alarm, and XFB is fire pump.

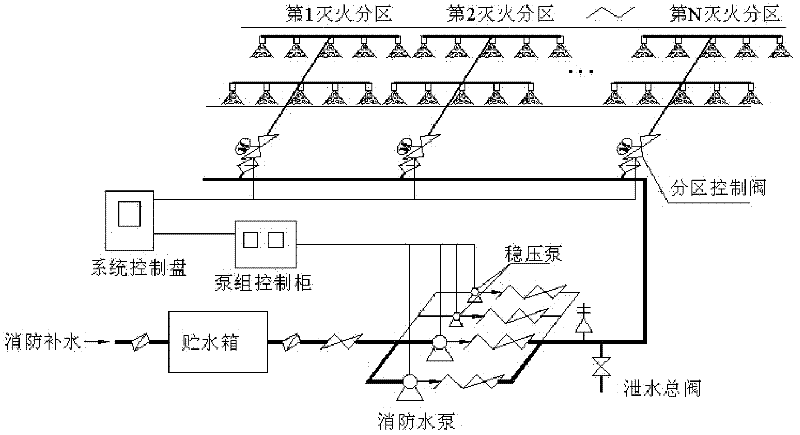

[0021] The waterway part of the system system of the present invention is composed of a fire pump, a water tank, a partition control valve, a fine water mist nozzle, and a pipe network composed of stainless steel pipes.

[0022] The fire pump consists of two high-pressure plunger pumps, one main and one standby. The plunger pump is fixed on the base of the pump set. A stop valve and a Y-type filter are installed at the water inlet of the pump set. The pipes are connected through high-pressure rubber joints. Set stop valve and high pressure check valve. The water tank includes a low water level alarm, a liquid level gauge, a float valve, a Y-shaped filter, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com