Planetary gear reducer with adjustable back lash

A technology of gear reducer and reducer, which is applied in the direction of belt/chain/gear, transmission device parts, mechanical equipment, etc., which can solve the problem of increased matching gap between planetary gear and pin shaft, increased backlash, and increased cost, etc. problem, to achieve the effect of improving the backlash accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

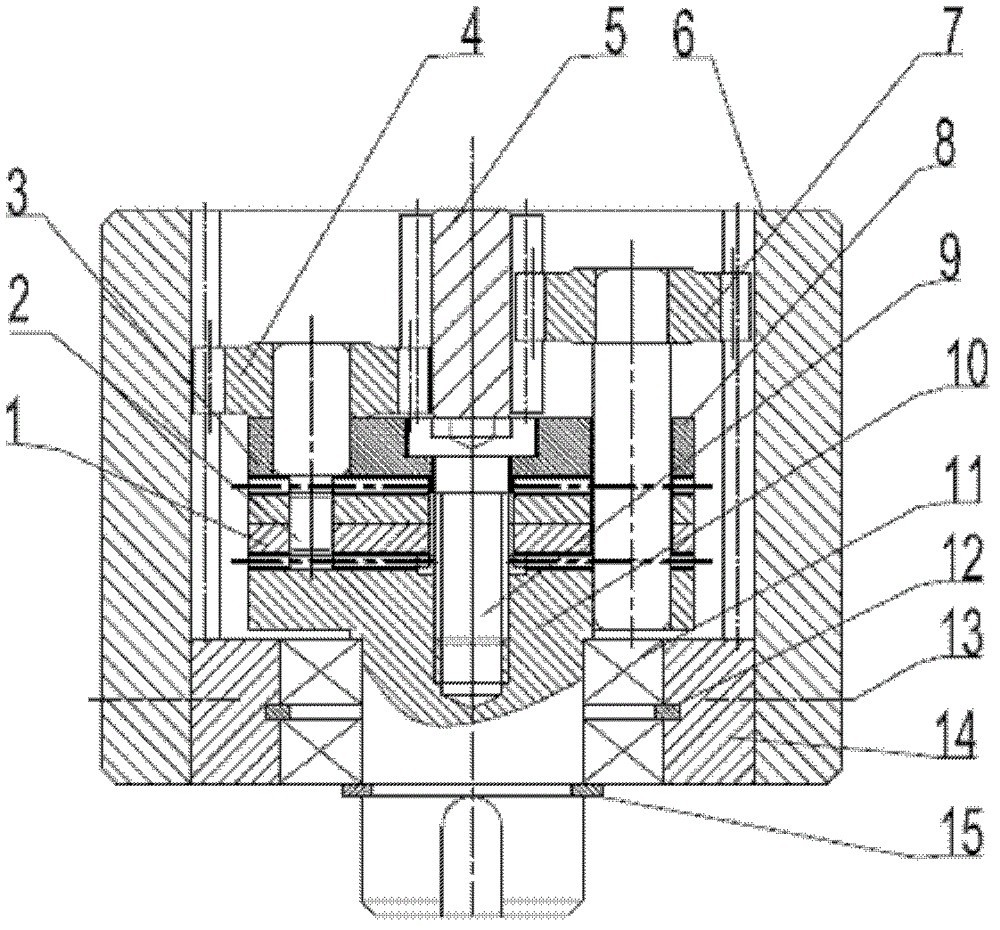

[0028] see figure 1 , This embodiment is a reducer for a solar automatic tracking device.

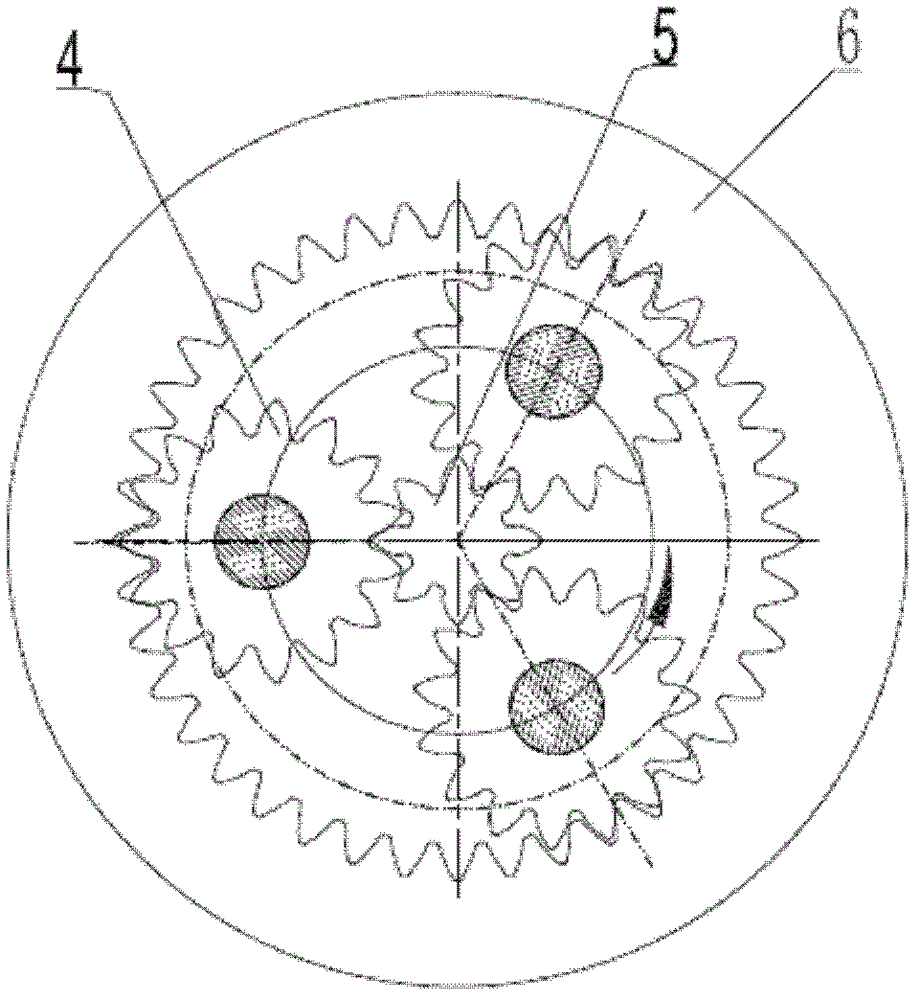

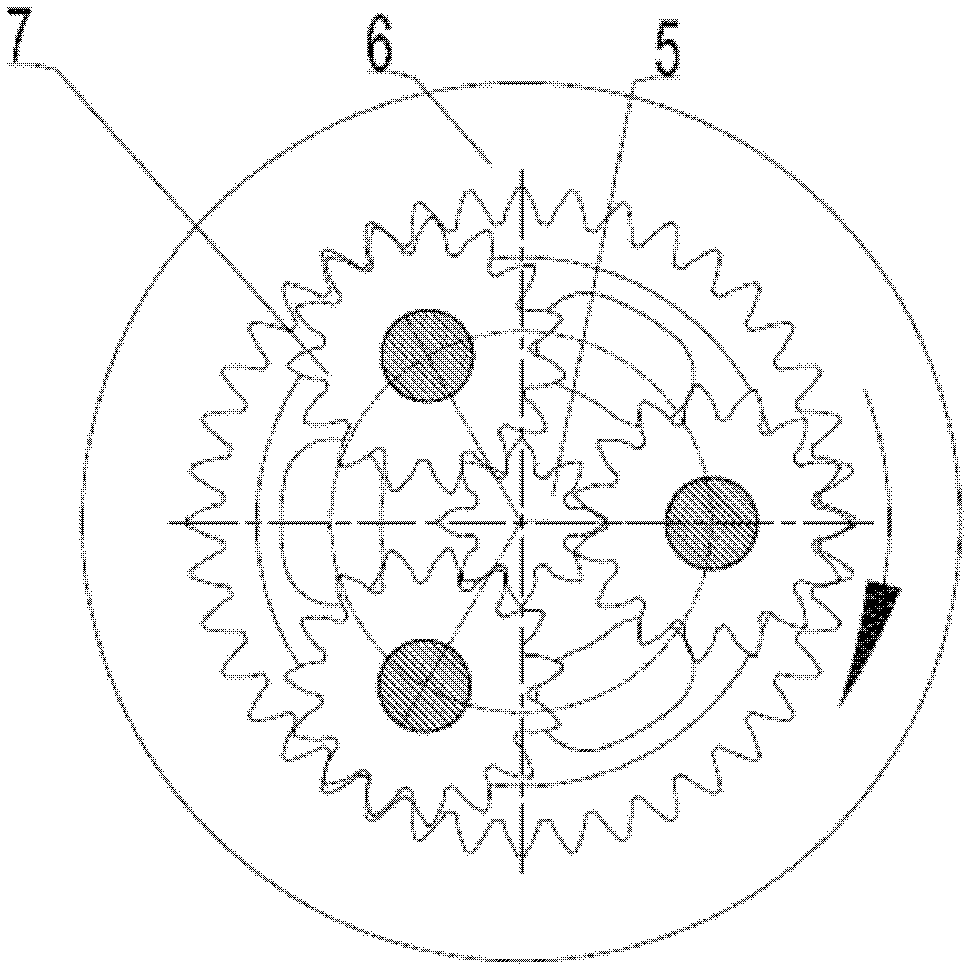

[0029] In the specific implementation, in the planetary gear reducer with adjustable backlash in this embodiment, the ring gear 6 is fixed and does not rotate, and the planetary gear teeth are respectively meshed with the external teeth of the sun gear 5 and the internal teeth of the ring gear 6, in a transmission There are two sets of planetary gear sets in the stage, that is, the first planetary gear set 7 and the second planetary gear set 4, on the contact surface between the first planetary gear carrier assembly 10 and the lower lock block 1 and the second planetary gear carrier assembly 8 and the The contact surfaces of the upper lock block 3 are respectively provided with interlocking end face teeth, and the lower lock block 1 and the upper lock block 3 are locked by the lock block pin 2; the radial ball bearing 11 is installed in the bearing housing 14 holes, and the holes are el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com