Data output transmission mechanism

A technology of transmission mechanism and data, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems that the accuracy cannot meet the set requirements, and the backlash of gear meshing is not eliminated, so as to eliminate the backlash of gear meshing, Effects of reduced sensitivity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

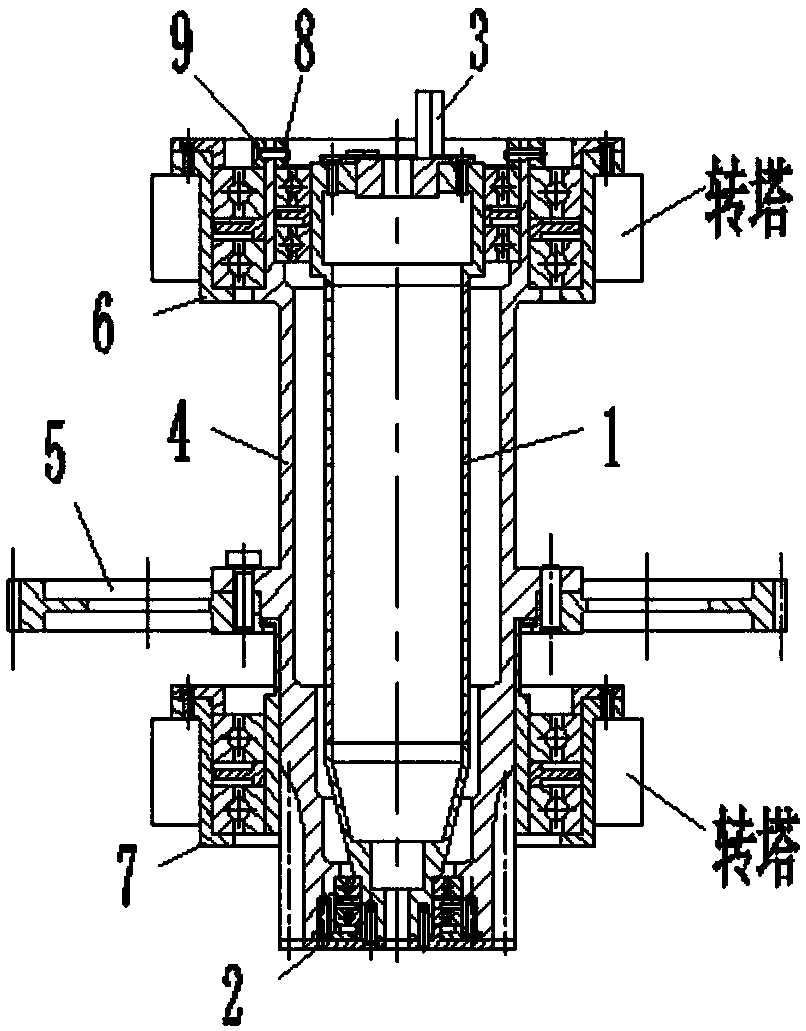

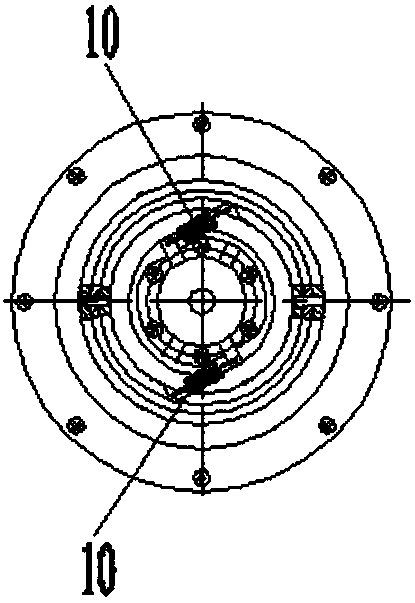

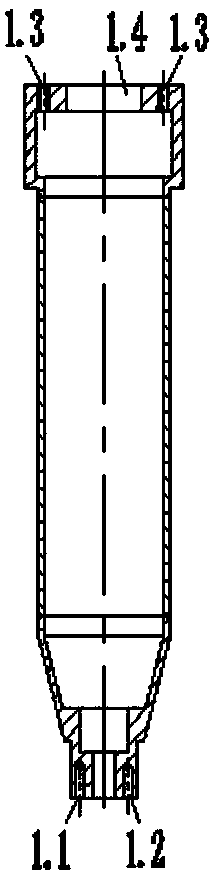

[0021] Embodiment of the present invention: the structural diagram of the data output transmission mechanism is as follows figure 1 and figure 2 As shown, it includes data output shaft 1, data output gear 2, data collector connection fork 3 and power input shaft 4. The data output shaft 1 and power input shaft 4 are thin-walled sleeve-shaped parts, and the power input The shaft 4 is set on the data output shaft 1, and the upper end and the lower end of the data output shaft 1 are respectively installed in the inner holes of the upper and lower ends of the power input shaft 4 through bearings; Cooperate with the power input shaft 4 through the hole shaft and then fix it axially through screws and positioning pins; the upper and lower ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com