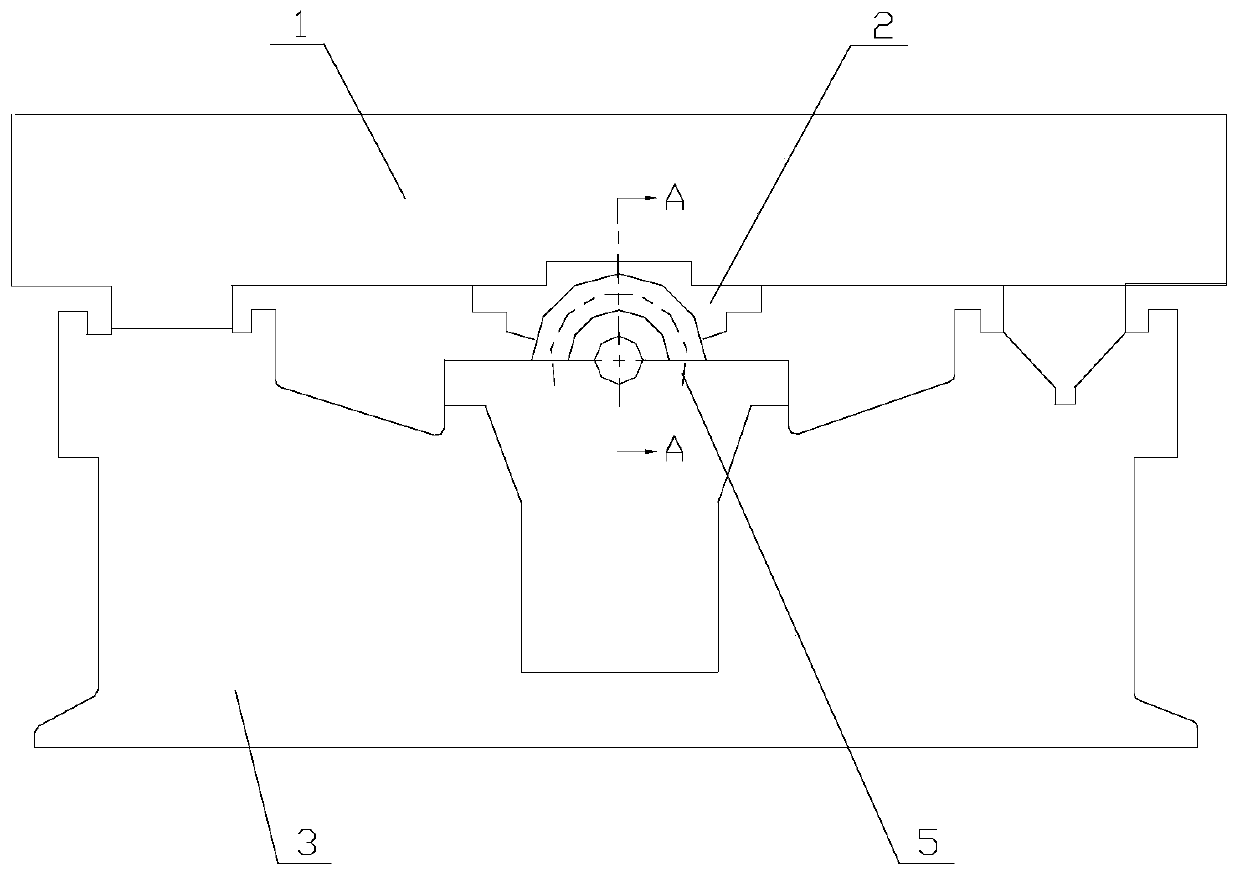

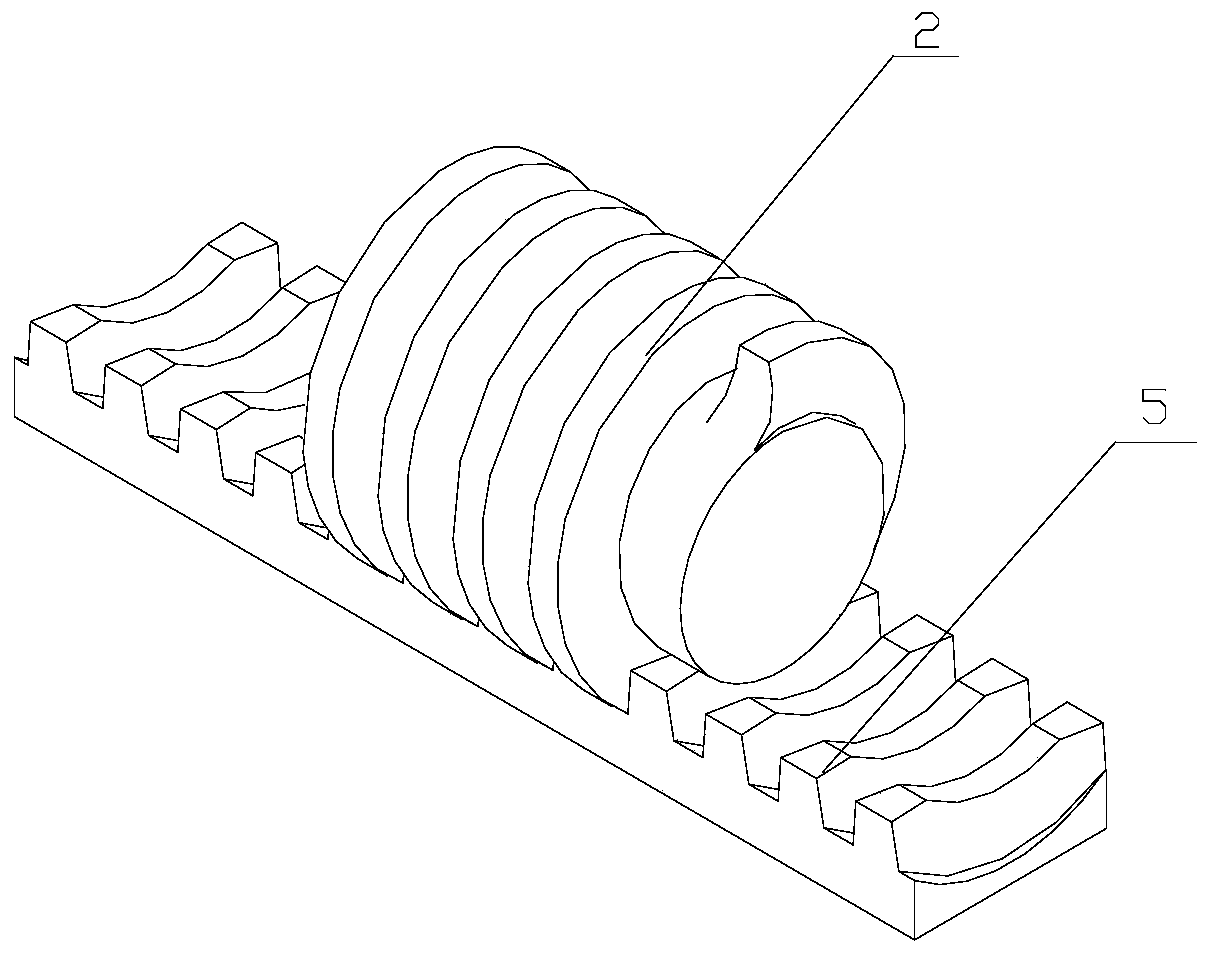

Repairing method suitable for worm and gear pair of heavy machine tool

A technology of heavy-duty machine tools and worm mothers, which is applied in the field of repairing the worm, worm and mother-bar pairs of heavy-duty machine tools, to achieve the effect of shortening the repair cycle and reducing the amount of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

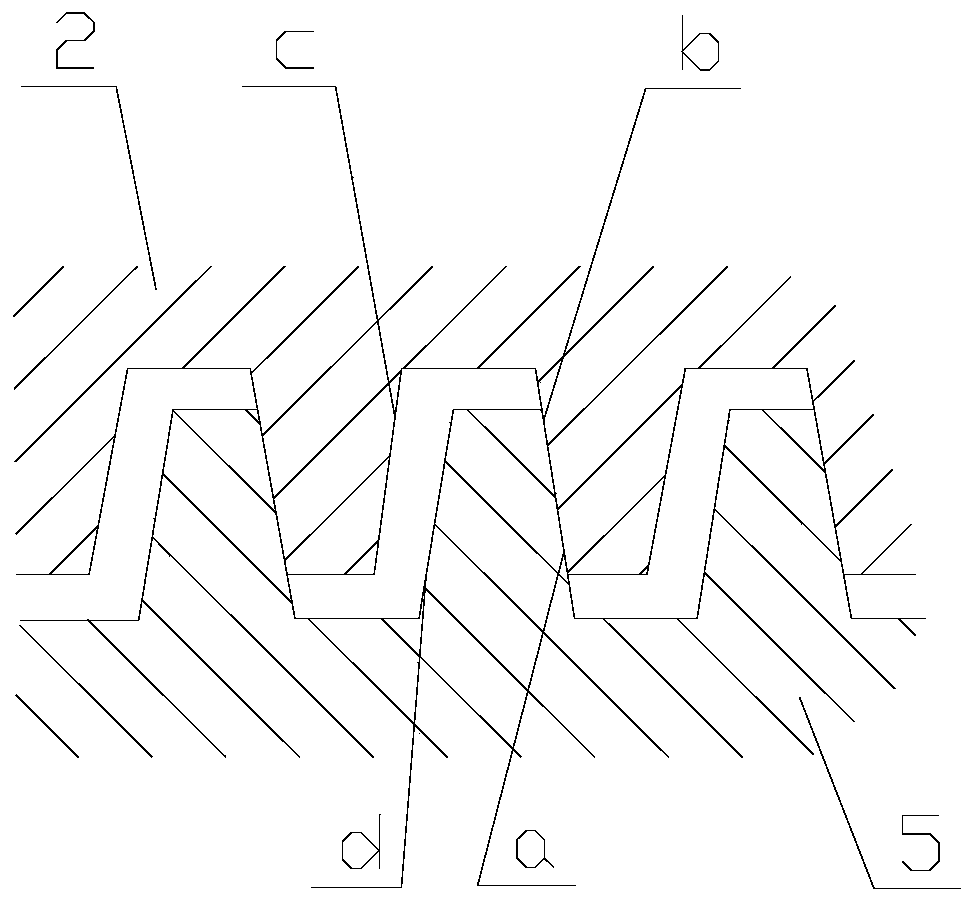

[0045]For the two meshing sides of the optically repaired worm bar in step S3, only the two meshing sides are optically repaired, and the middle section of the worm bar with the most serious wear is lightly repaired first, so that the dimensions between the teeth of all the worm bars are kept consistent. In an optional implementation mode here, for the optical repair operation of the worm bar, for example but not limited to the optical repair method disclosed in the publication number CN202010796U can be used. This embodiment adopts the scheme of directly performing light repair on the worm bar, which reduces the process of roughly matching and scraping the old worm bar in the prior art, which greatly reduces the labor of the repair fitter and shortens the repair period.

[0046] More specifically, the distribution of the worm in step S4 includes:

[0047] S41: In order to ensure the meshing quality of the worm and worm bar pairs, put the new worm car into semi-finished spare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com