LED lights based on composite cooling technology

A kind of LED lamp technology, which is applied in the direction of lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problem of large thermal resistance between aluminum substrate and thermal conductive adhesive, heat dissipation cannot be solved, and heat cannot be timely Dispersion and other problems, to achieve the effect of not easy to fall off, small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

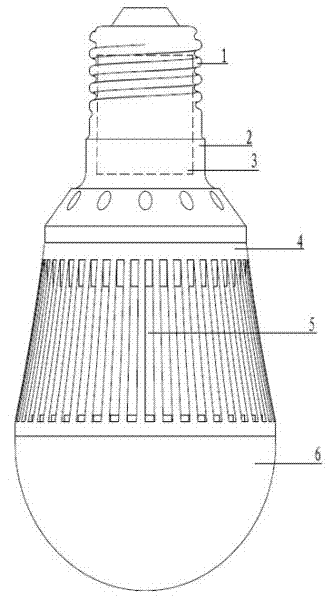

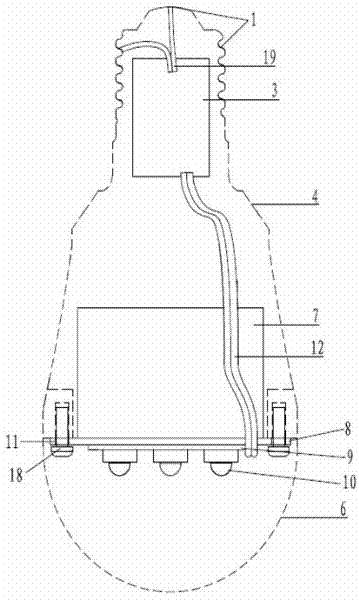

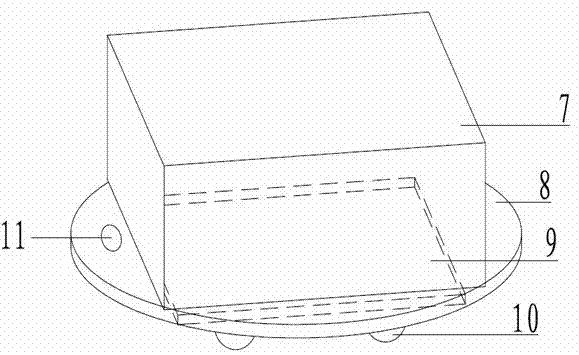

[0018] Such as Figure 1-5 As shown, the LED lamp based on the compound heat dissipation technology of the present invention includes three parts: a housing unit, a lamp group unit and a power supply unit. Wherein, the lamp group unit and the power supply unit are fixed in the shell unit, and the lamp group unit is connected with the power supply unit. The shell unit includes: a metal lamp cap 1 , a plastic lamp cap 2 , a shell 4 , and a lampshade 6 . The lamp unit includes porous copper 7 , aluminum plate 8 , ceramic substrate 9 and LED tube 10 . The power supply unit includes a power supply 3 , a power supply AC input line 12 , and a power supply DC output line 19 . The present invention utilizes composite technology to effectively dissipate heat through the casing, the ceramic substrate 9 and the porous copper 7 by fully utilizing conduction, convection and radiation heat dissipation methods, so that the LED bulb can work under high power conditions.

[0019] 1. Shell un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com