Light motor

A kind of electric motor, light and handy technology, applied in the field of electric motor, can solve the problems such as unfavorable vehicle miniaturization, simplification, increase of material and assembly cost, easy to be stained with dust of the motor, and achieve the reduction of material cost, simple structure, and reduction of production and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

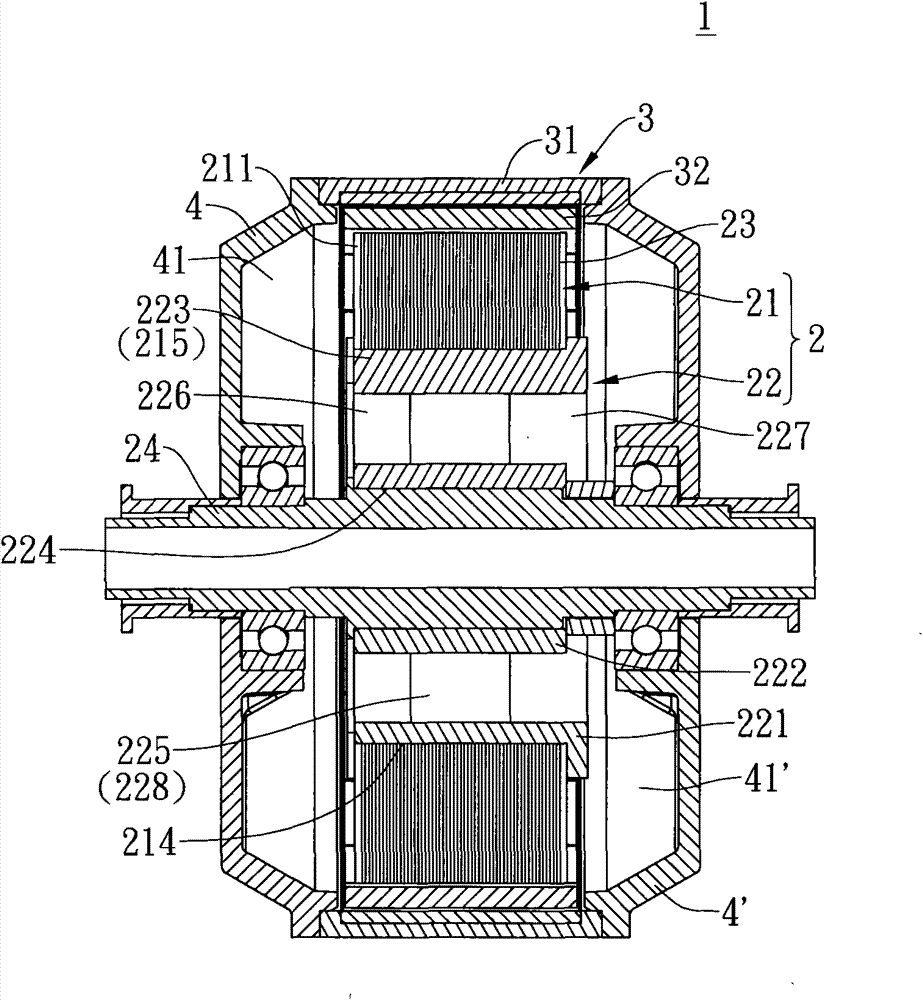

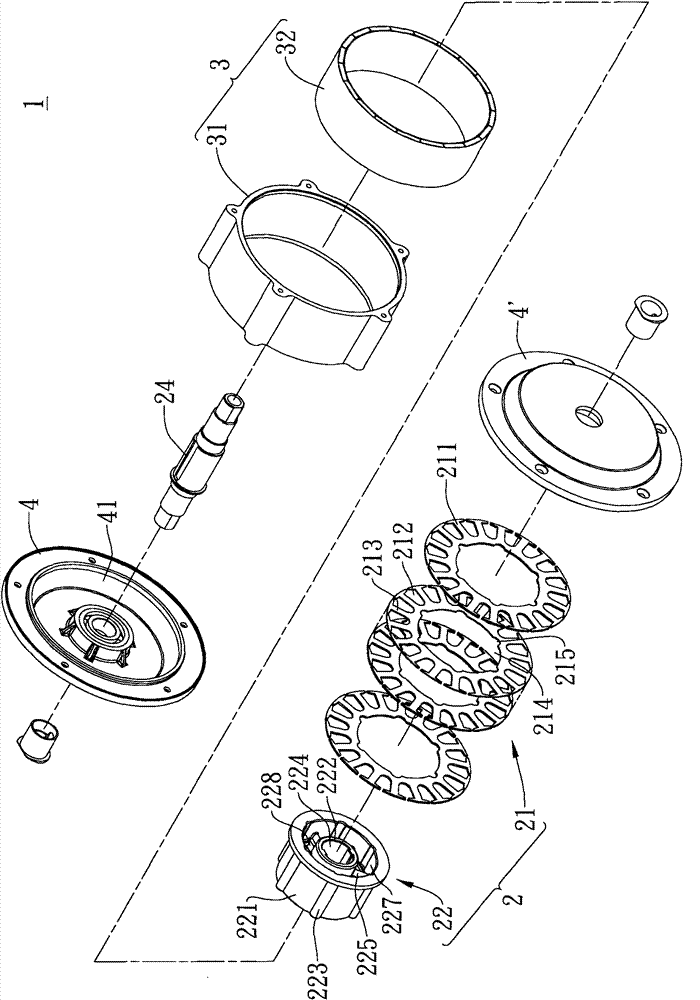

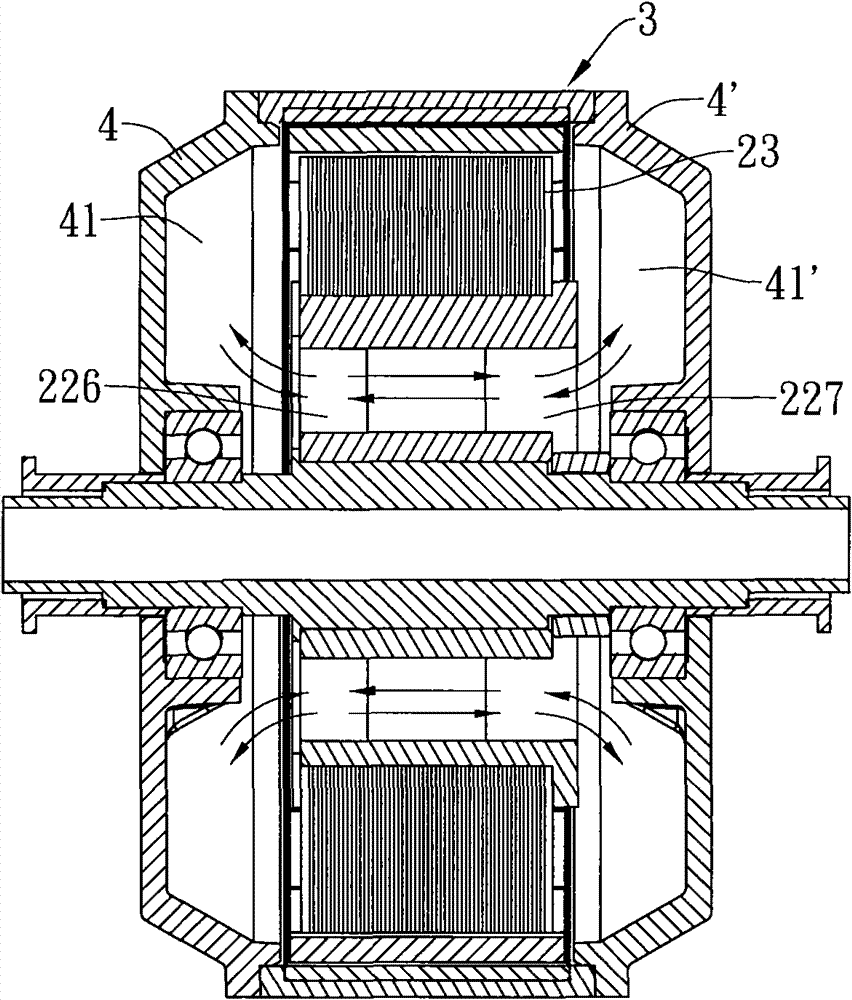

[0038] see figure 1 , figure 2 As shown, it is a preferred embodiment of the lightweight motor 1 of the present invention, including a stator 2, a rotor 3 and left and right side covers 4, 4'.

[0039] The stator 2 includes a silicon steel sheet group 21 and an inner bushing 22 . The silicon steel sheet group 21 is formed by stacking a plurality of silicon steel sheets. The left and right sides of the silicon steel sheet group 21 are respectively provided with insulating sheets 211 to sandwich the silicon steel sheet group 21 therein. A plurality of slots 212 are annularly provided on the periphery of the silicon steel sheet group 21 , and a rib 213 is formed between each adjacent slot 212 for the winding of the coil group 23 . Moreover, the silicon steel sheet group 21 is provided with a central hole 214 , and a plurality of grooves are annularly arranged on the periphery of the central hole 214 , and the grooves are used as the first embedding portion 215 .

[0040] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com