Saw blade grinding machine

A grinding machine and saw blade technology, which is used in metal sawing equipment, tool dressing of sawing machines, metal processing equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

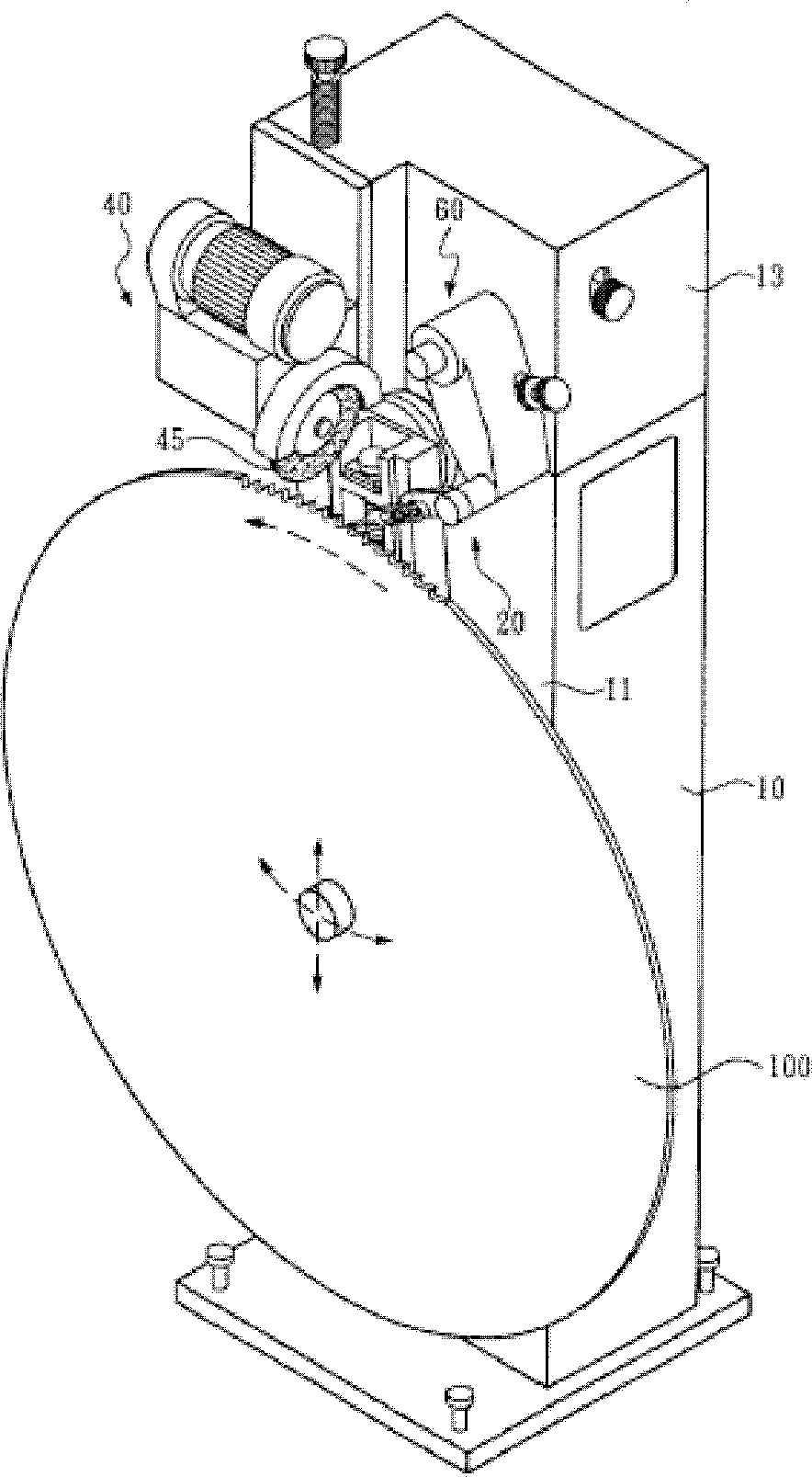

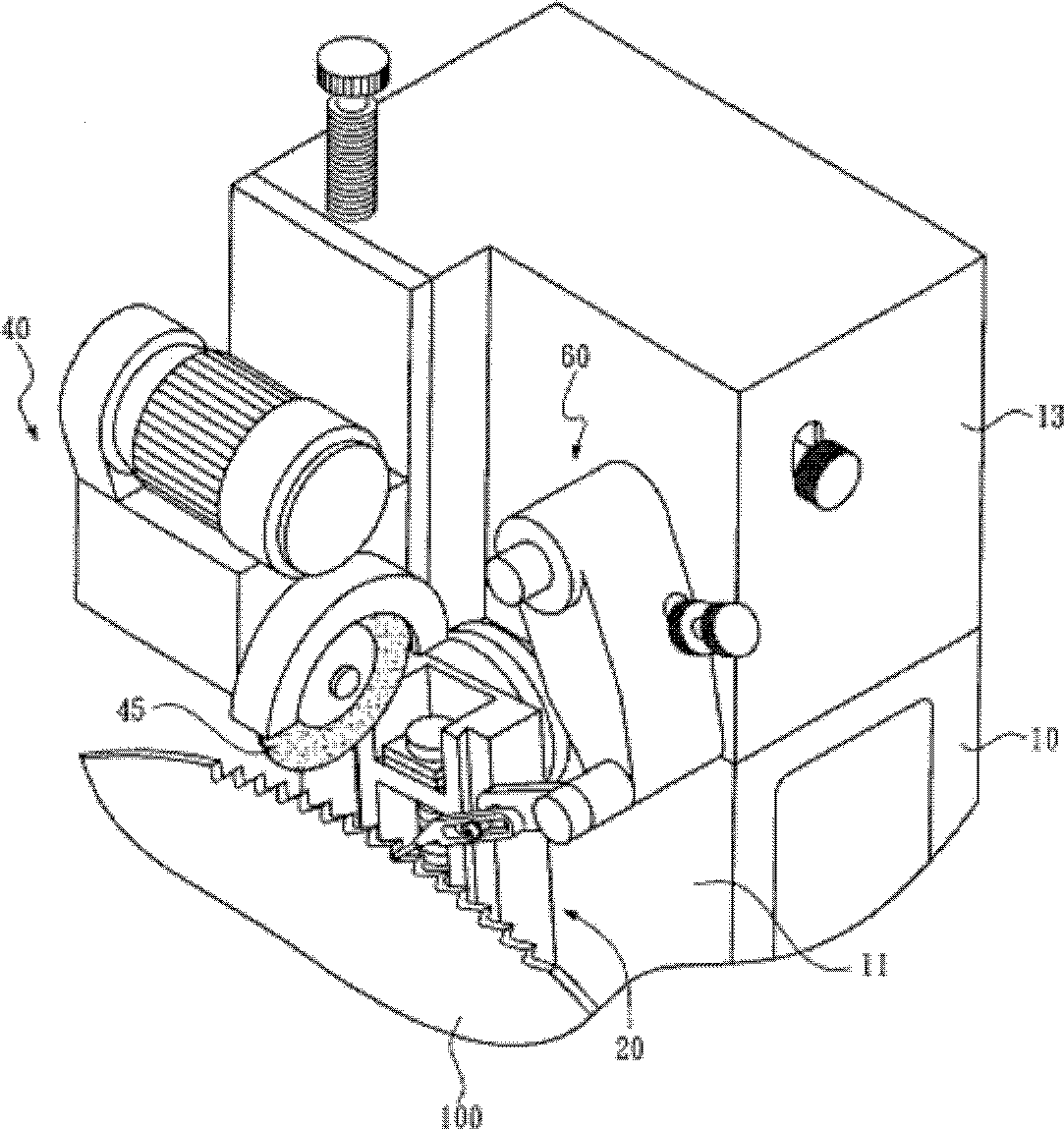

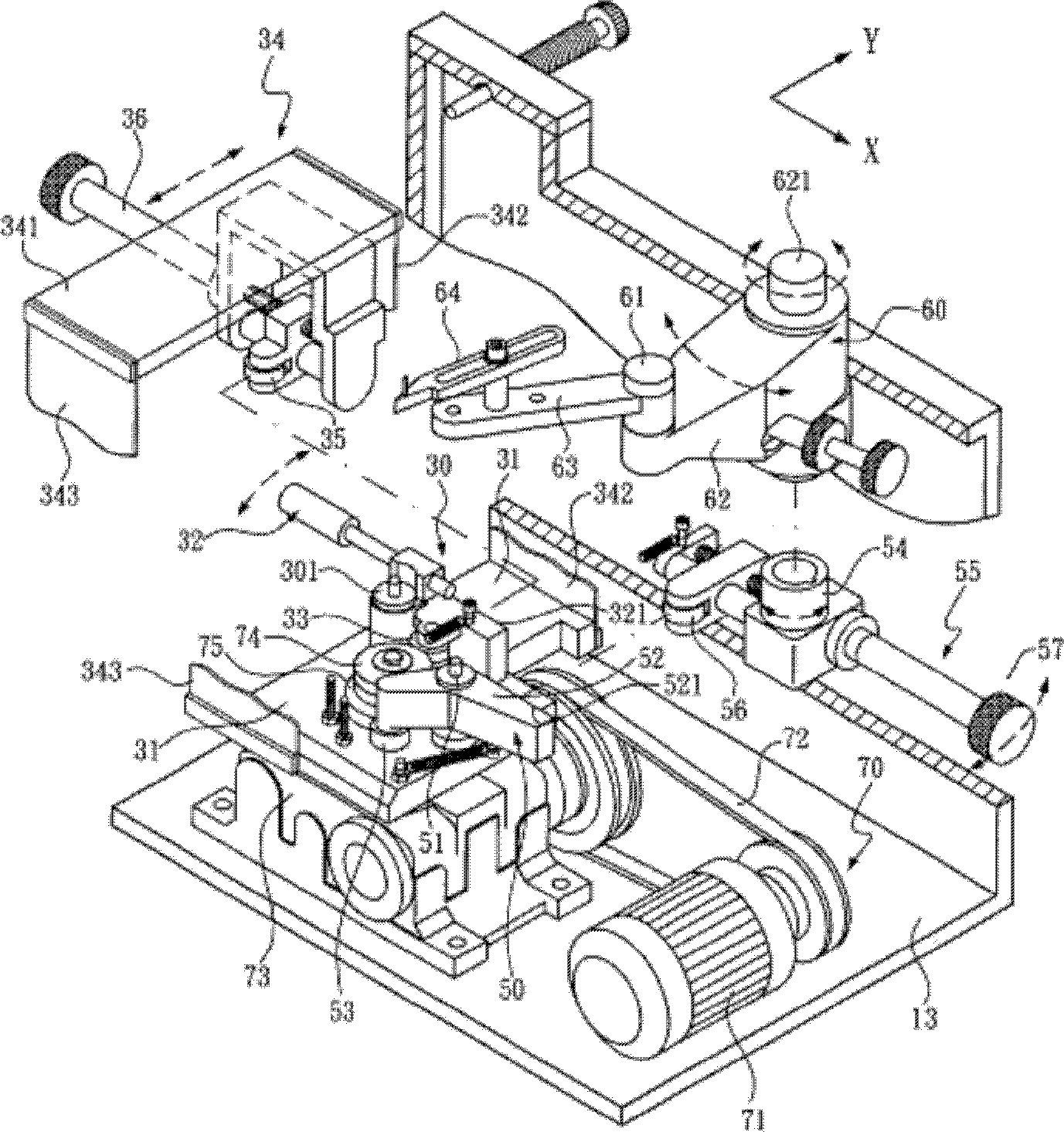

[0031] see figure 1 , shows a three-dimensional schematic view of the saw blade grinder of the present invention, the grinder is a vertical grinder, which includes a machine base 10, a saw blade positioning device 20, a grinding wheel feeding device 30, a grinding wheel device 40, and a saw blade feeding device 50 , saw blade mover 60 and power unit 70 .

[0032] Wherein, the base 10 is upright and has a plurality of through holes around its bottom, which can be fixed on the ground by a fixing device.

[0033] Wherein, the saw blade positioning device 20 is fixed on the vertical wall plate 11 of the machine base 10 , the saw blade positioning device 20 can position the saw blade 100 and adjust the center position of the saw blade 100 .

[0034] Wherein, the grinding wheel feeding device 30 is arranged on the cabinet 13 at the top of the base 10 .

[0035] Wherein, the grinding wheel device 40 can be controlled by a grinding wheel feeding device to reciprocate up and down, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com