Broken rope protective device of upright lift gate

A technology of broken rope protection and lifting doors, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems of increased volume of spring and connecting rod mechanism, no specific structure given, and large volume of protective devices, so as to simplify the structure and install Convenient, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

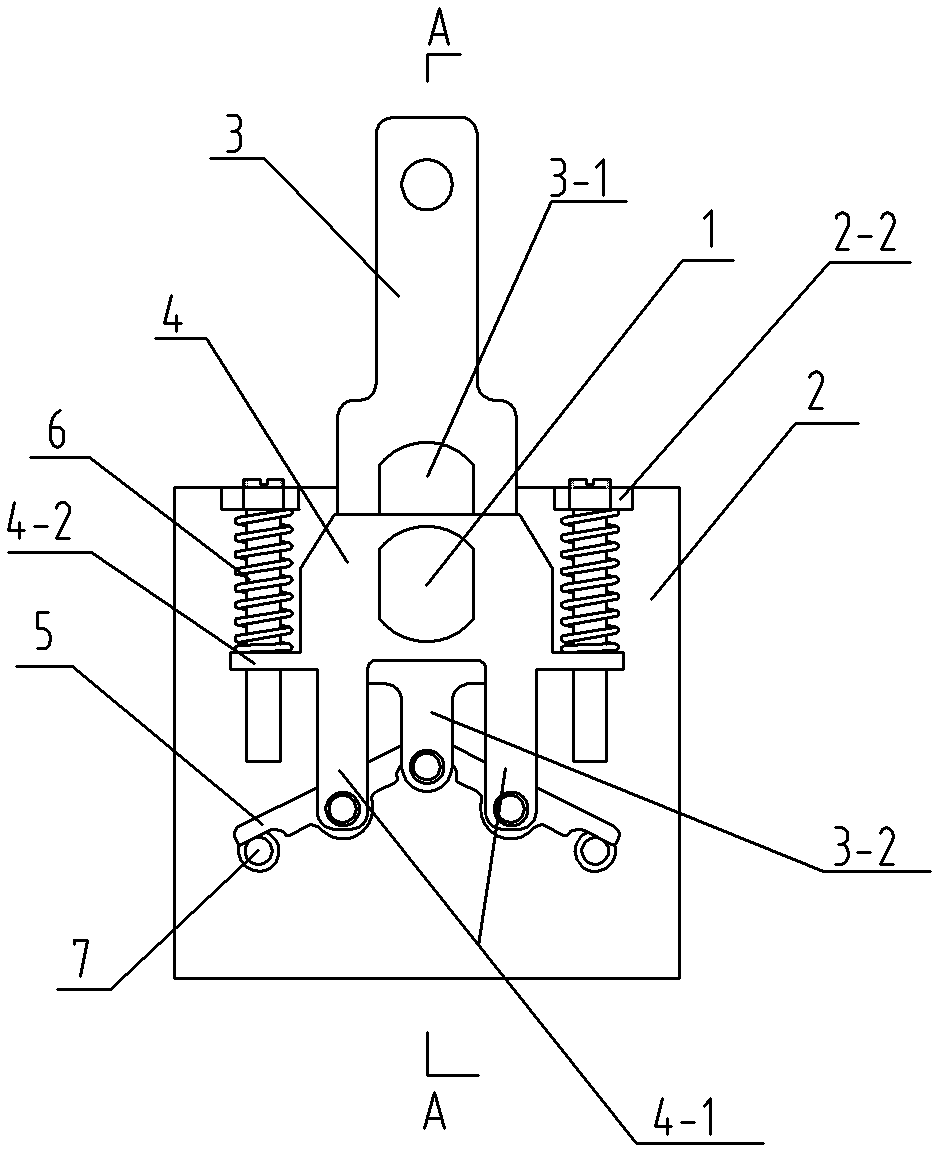

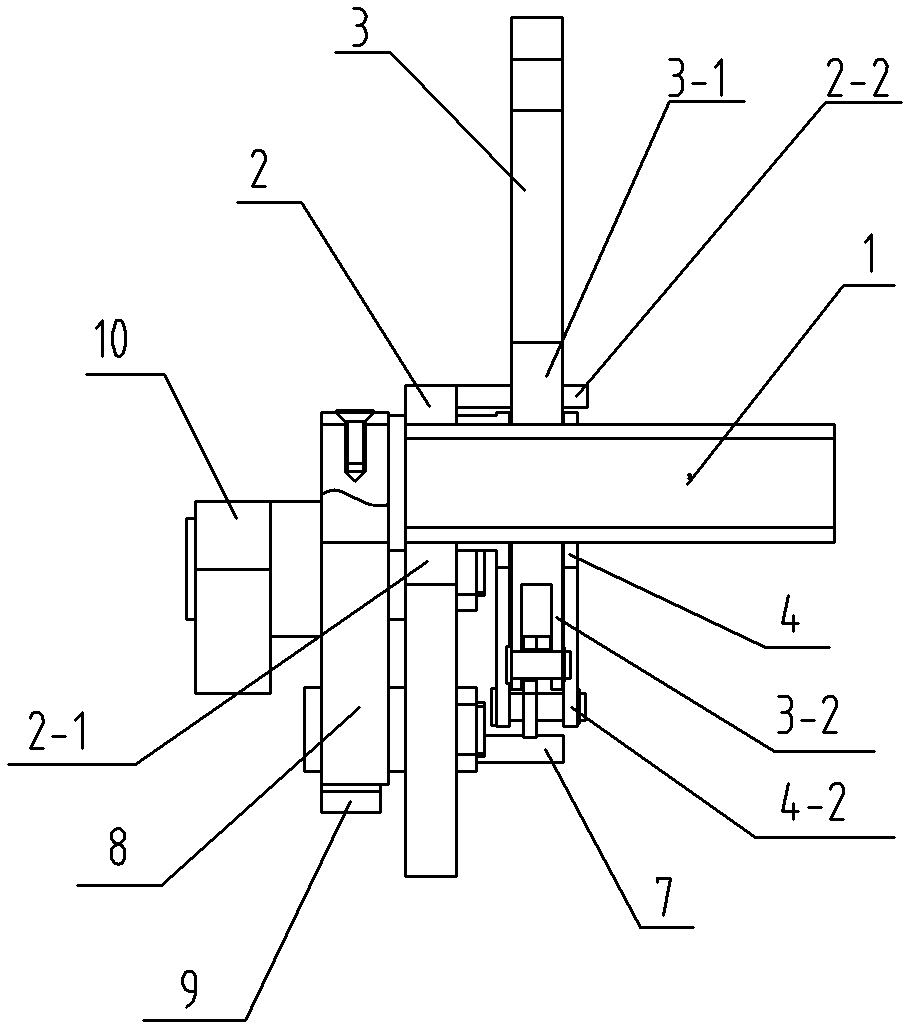

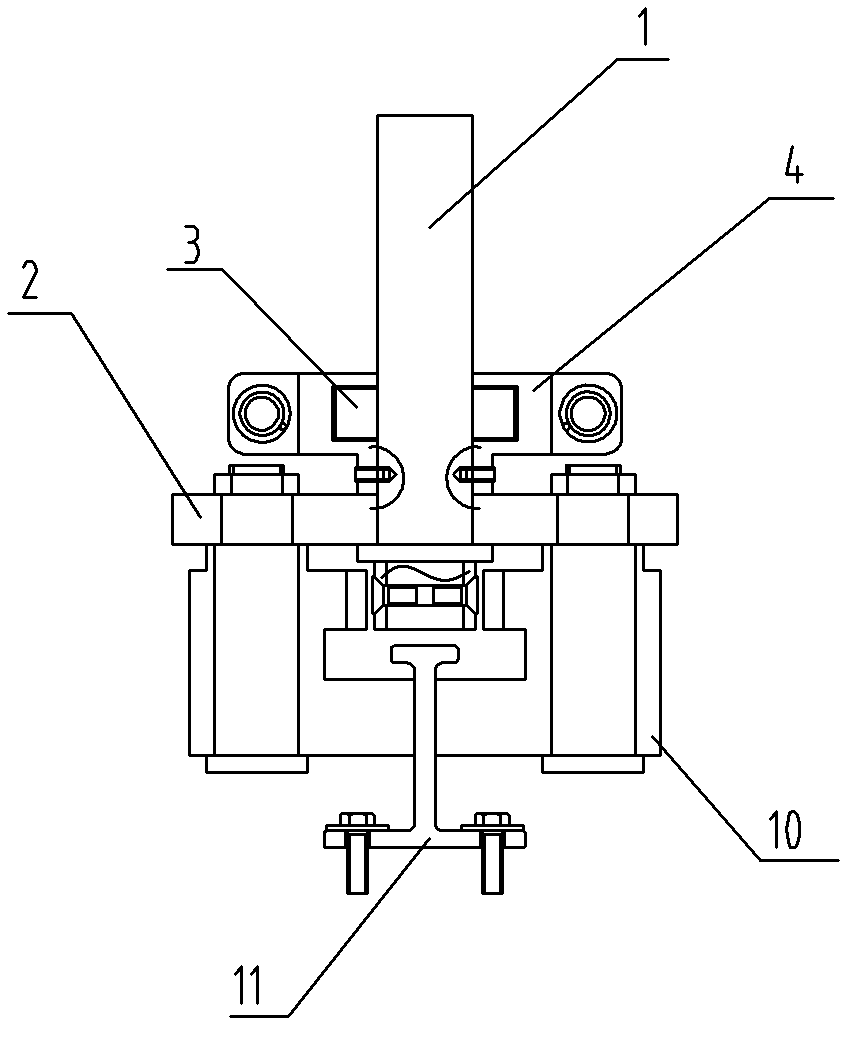

[0023] see figure 1 , 2 , 3, it has a load-bearing shaft 1, one end of the load-bearing shaft is connected with the vertical lifting door, and the other end is provided with a mounting base plate 2, and the mounting base plate 2 passes through a long strip-shaped sliding hole 2 of the load-bearing shaft -1 is installed on the load-bearing shaft 1, the mounting substrate can slide up and down relative to the load-bearing shaft 1, and its sliding range is limited by the length of the elongated sliding hole 2-1, and the load-bearing shaft 1 is a flat shaft Or a square shaft to ensure that it does not rotate circumferentially during sliding. A broken rope trigger mechanism is installed on one side of the installation base plate 2, the broken rope trigger mechanism has a linkage lug 3 and a bracket 4, and the linkage lug 3 is set through its elongated lug hole 3-1 On the load-bearing shaft 1, the bracket 4 is fixed together with the load-bearing shaft 1; a pair of levers 5 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com