Euchroic-displaying multi-groove section fiber and preparation method thereof

A technology of grooves and fibers, which is applied in the field of real-color multi-groove cross-section fibers and its preparation, can solve the problems of poor color performance, light appearance color, waxy hand feeling, etc., and achieve the elimination of surface waxy feeling, preparation The method is simple, and the effect of improving the moisture-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Make 222.2dtex / 24F PET DTY filament.

[0037] Raw material: PET, intrinsic viscosity (0.675±0.015)dL / g, melting point 240~255℃

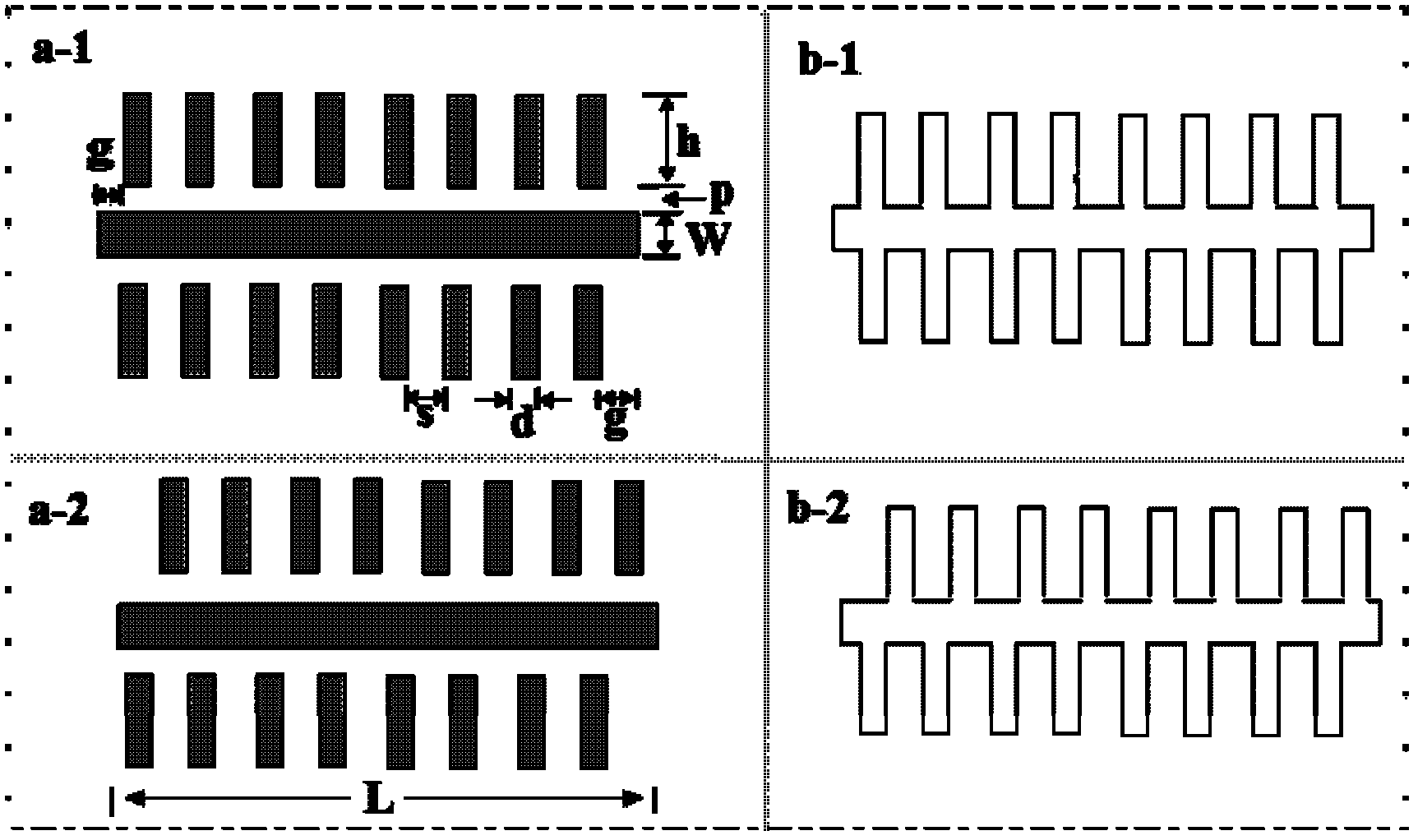

[0038] The spinneret hole design is as figure 1 As shown in (a-1), the spinneret hole parameters are d=0.05mm, s=0.10mm, h=0.15mm, g=0.05, L=1.05mm, p=0.02mm, W=0.10mm, 2×6 (6 grooves on both sides, the same below) grooves.

[0039] Use Foume110L vacuum drum dryer to dry PET slices (process conditions: temperature 145°C, time 48h; moisture content after drying 50ppm) to obtain dry slices with good uniformity, and send them into ABEΦ25×2 screw extrusion The spinning machine melts and extrudes, enters the spinning assembly through the melt pipe, is sprayed out from the spinneret, and then is cooled by side blowing, oiled, wound, and doffed to obtain POY filaments, and finally deformed by the first hot box, false The twister, the second hot box for shaping, oiling and winding, the specific spinning process parameters are shown in Table 1.

Embodiment 2

[0041] Make 111.1dtex / 24F polyester PET DTY filament.

[0042] Raw material: PET, intrinsic viscosity 0.496±0.015)dL / g, melting point 240~251℃.

[0043] spinneret holes such as figure 1 As shown in (b-1), the spinneret parameters are d=0.05mm, s=0.10m, h=0.15mm, g=0.05, r=0.05, L=0.60mm, W=0.10mm, 2×3 grooves groove.

[0044] Use Foume110L vacuum drum dryer to dry PET slices (process conditions: temperature 145°C, time 48h; moisture content of slices after drying 50ppm) to obtain dry slices with good uniformity, and send them into the screw extrusion model ABEΦ25×2 Out of the spinning machine, it is melted and extruded, enters the spinning assembly through the melt pipe, is sprayed out from the spinneret, and then is cooled by side blowing, oiled, wound, and doffed to obtain POY filaments, and finally deformed by the first hot box, False twister, second hot box setting, oiling and winding, the winding speed is 800m / min, and other spinning process parameters are the same as...

Embodiment 3

[0046] Make 111.1dtex / 36F polyester PTT DTY filament.

[0047] Raw material: PTT, intrinsic viscosity (1498±0.015)dL / g, melting point 228~233℃.

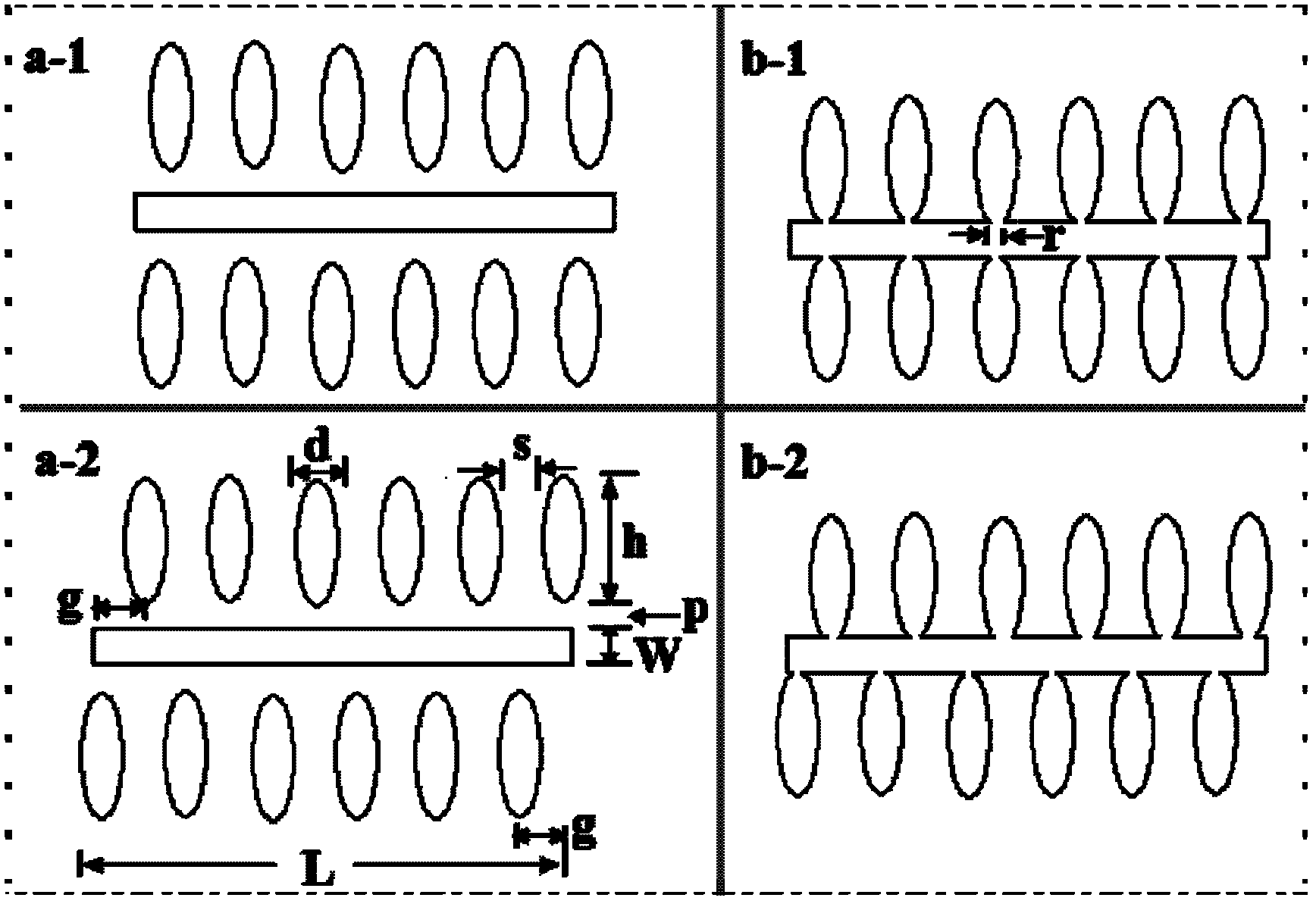

[0048] spinneret holes such as figure 2 As shown in (a-1), the spinneret parameters are d=0.08mm, s=0.10mm, h=0.12mm, g=0.05m, L=0.64mm, p=0.02mm, W=0.10mm, 2× 3 grooves.

[0049] Use Foume110L vacuum drum dryer to dry PET slices (process conditions: temperature 120°C, time 48h; moisture content of slices after drying 30ppm) to obtain dry slices with good uniformity, and send them into the screw extrusion model ABEΦ25×2 Out of the spinning machine, it is melted and extruded, enters the spinning assembly through the melt pipe, is sprayed out from the spinneret, and then is cooled by side blowing, oiled, wound, and doffed to obtain POY filaments, and finally deformed by the first hot box, The specific spinning parameters of the false twister, the second hot box for shaping, and oiling and winding are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com