Double-cross sectional dark fiber and preparation method thereof

A font-shaped and cross-section technology, which is applied in the field of double cross-section fiber and its preparation, can solve the problems of poor color performance, waxy hand feeling, light appearance color, etc., so as to eliminate the waxy feeling on the surface, improve the moisture permeability, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 50

[0031] Example 1 Preparation of 150dtex / 36f dark-color PET filament and its dark-color effect

[0032] Raw material: polyethylene terephthalate chip (hereinafter referred to as PET chip), intrinsic viscosity (0.678±0.015) dL / g, melting point 240~255℃

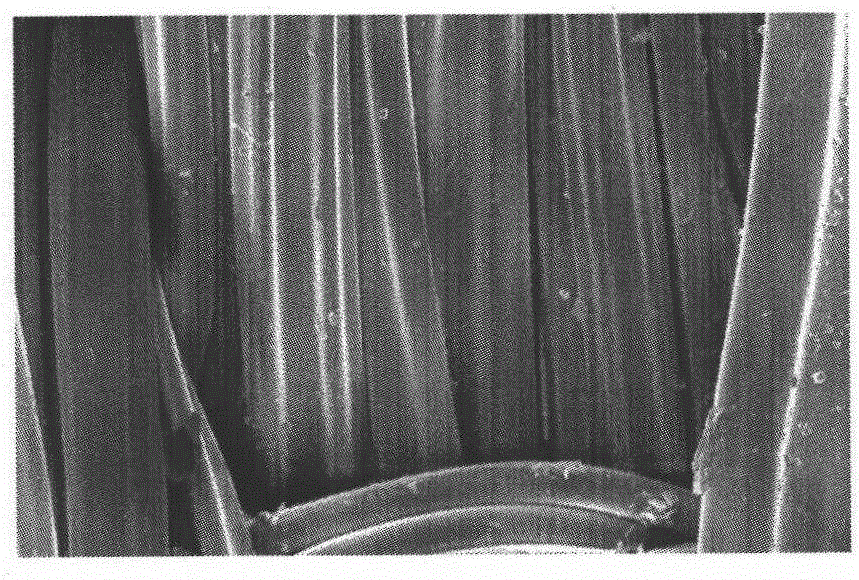

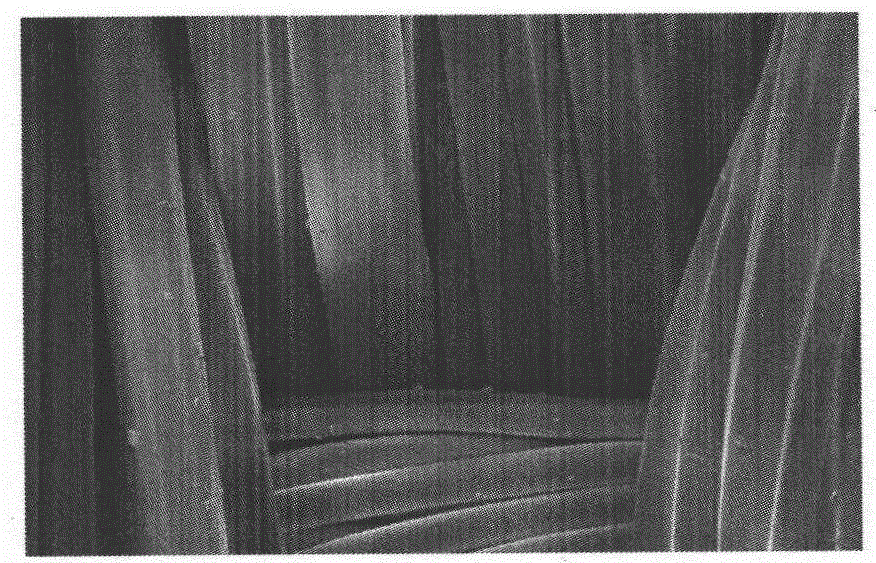

[0033] Spinneret design: the spinneret used in this embodiment is as image 3 As shown, 36 single fiber spinneret holes 2 are arranged on the spinneret 1 . The lateral dimension of spinneret 1 is as Figure 4A As shown, a stepped structure is adopted, and its thickness D is 15mm. Among them, the diameter d1 of the large cylinder part is 99.5±0.05mm, the diameter d2 of the small cylinder part is 89.6-90.2mm, and the thickness D1 of the small cylinder part is The diameter of the large hole d3 in the stepped hole is 18mm, the diameter of the small hole d4 is 11mm, and the diameter d5 of the inlet slot corresponding to each single fiber spinneret hole 2 is 12mm. Such as Figure 4BAs shown, the single fiber spinneret hole 2 is lo...

Embodiment 2 20

[0046] Example 2 Preparation of 120dtex / 36f dark-color filament and its dark-color effect

[0047] Raw material, spinneret, spinning equipment: with embodiment one

[0048] Spinning process: the difference from Example 1 is to reduce the extrusion rate of the spinning melt, and the spinning temperature of screw rod 2 and 3 zones and the spinneret assembly are all increased by 3 ° C, and the rest of the process is the same as in Example 1, so The linear density of the fiber can be reduced. PET control filaments of 120 dtex / 36f were spun with circular cross-section spinnerets under the same process equipment.

[0049] Preparation of woven fabric sample: same as in Example 1.

[0050] Dark color test results: The test results obtained by using the test method described in Example 1 are shown in Table 3. Compared with conventional round-section fiber fabrics, double-cross-section fiber fabrics have lower L and a values, and can obtain a more pure dark color effect. Both the K / S...

Embodiment 3 00

[0053] Example 3 Preparation of 100dtex / 36f dark-color filament and its dark-color effect

[0054] Design of spinneret hole size parameters: L=0.60±0.01mm, W=0.30±0.01mm, S=0.10±0.01mm, M=0.10±0.01mm for a single fiber spinneret hole, other parts of the spinneret design Same as Embodiment 1.

[0055] The raw materials, spinning equipment and spinning process are all the same as in Example 1; under the same process equipment, two kinds of PET comparison filaments of 100dtex / 36f were spun with the above-mentioned double cross spinneret and circular cross-section spinneret respectively.

[0056] Preparation of knitted fabrics: Since the warps of the two groups of woven fabrics prepared above are all round-section fibers, some round-section fibers will appear on the surface of the fabrics, which will weaken the dark effect of the double cross weft. In this embodiment, weft-knitted fabrics are made entirely of double cross fibers, and contrast knitted fabrics with the same structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com