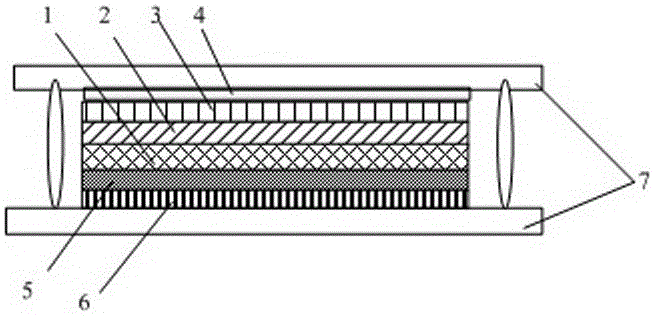

A composite photoanode for paper-type perovskite solar cells and its preparation method

A technology of solar cells and composite light, which is applied in the field of solar electrode materials, can solve the problems of difficult internal charge transmission and low photoelectric conversion efficiency, and achieve the effects of improving photoelectric conversion efficiency, promoting absorption and charge collection, and good light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

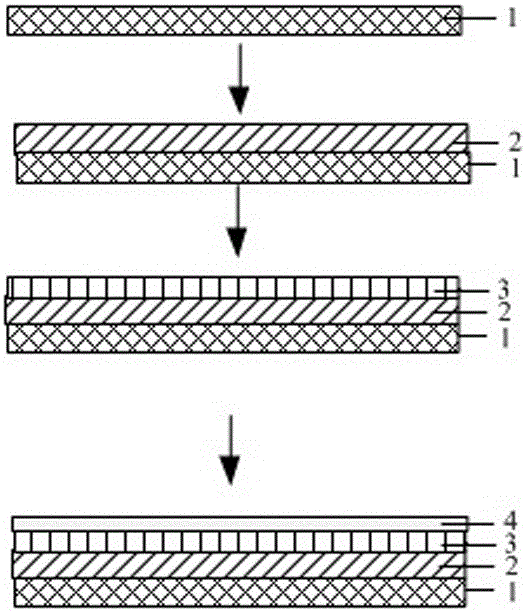

Method used

Image

Examples

Embodiment 1

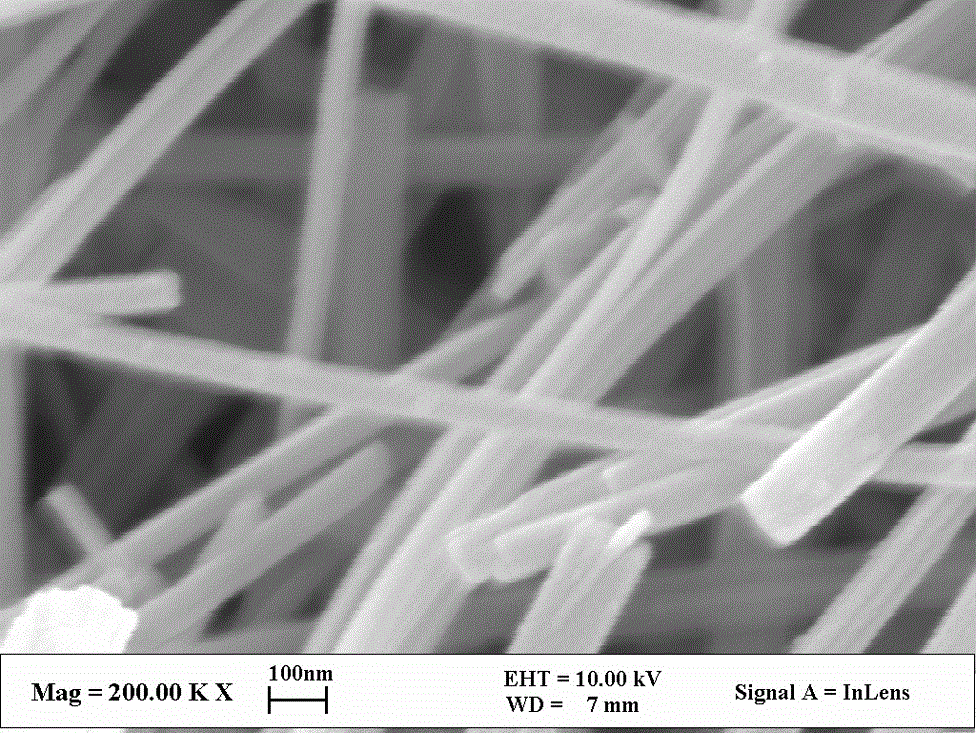

[0060] (1) Nanofibers were synthesized by hydrothermal method: raw materials were 0.2g P25 powder (P25 refers to nano-titanium dioxide) + 30ml deionized water + 12g NaOH, hydrothermal reaction at 200°C for 96h to obtain nanofiber slurry.

[0061] (2) surfactant F-127 is added in the nanofiber slurry again, the massfraction of surfactant F-127 is 0.1% of the nanofiber slurry quality, to improve the dispersibility of nanofiber in the slurry, and Stir and mix to form a well-dispersed nanofiber precursor slurry.

[0062] (3) The precursor slurry prepared in step 2 is made into a nano-paper blank by hot-pressing a film-forming method.

[0063] (4) Carry out sintering treatment on the nano paper blank, the sintering conditions are respectively 500° C. for 30 min to obtain the nano paper, and then naturally cool to room temperature, the thickness of the nano paper is about 0.5 μm.

[0064] (5) Disperse the Minhua raw material in DMF, an organic solvent, and filter. Filtrate, PbCl ...

Embodiment 2

[0076] On the basis of Example 1, select its No. 10 sample nanopaper preparation conditions, that is, the composition is 0.01% graphene+titanium oxide by mass fraction, the sintering system is 500°C-30min, and the film thickness is 0.5μm nanopaper, change The photoelectric conversion efficiency of the paper-type perovskite solar cell is shown in Table 2 below under the premise of other parameters such as the precursor composition / concentration of the metal organic halide, the sintering system, and the film thickness.

[0077] Table 2 Effects of different sensitizer layer compositions and preparation processes on the photoelectric conversion efficiency of the battery

[0078]

[0079] It can be seen from Table 2 that the precursor composition, concentration, solvent composition and CH 3 NH 3 The concentration of the isopropanol solution of I and the soaking time have a significant impact on the photoelectric conversion efficiency of the battery. The film-forming method, thic...

Embodiment 3

[0081] On the basis of Example 2, select the nano paper preparation conditions of No. 10 sample of Example 1 (that is, the composition is a mass fraction of 0.01% graphene+titanium oxide, the sintering system is 500°C-30min, and the film thickness is 0.5 μm nano paper) and the sensitizer layer preparation condition of the No. 1 sample of embodiment 2 (the PbCl of 80mg / ml 2 +350mg / ml of PbI 2 +40mg / ml CH 3 NH 3 I, organic solvent selects DMF, the CH of 30mg / ml for use 3 NH 3 Soak in the isopropanol solution of I for 60s, prepare a sensitizer layer with a thickness of 0.5 μm by drop coating, and undergo a heat preservation treatment at 70° C. for 30 minutes), change the dense TiO x The preparation method of the connecting layer and the transparent conductive film is optimized to optimize its performance, and the photoelectric conversion efficiency of the paper-type perovskite solar cell is obtained as shown in Table 3 below under the premise that other conditions remain unch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com