A solar cell module

A technology of solar cells and solar cells, applied in the field of solar cells, can solve the problems of rising working temperature, affecting the performance of cells, and inability to make full use of sunlight, etc., to achieve the effect of increasing output power and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

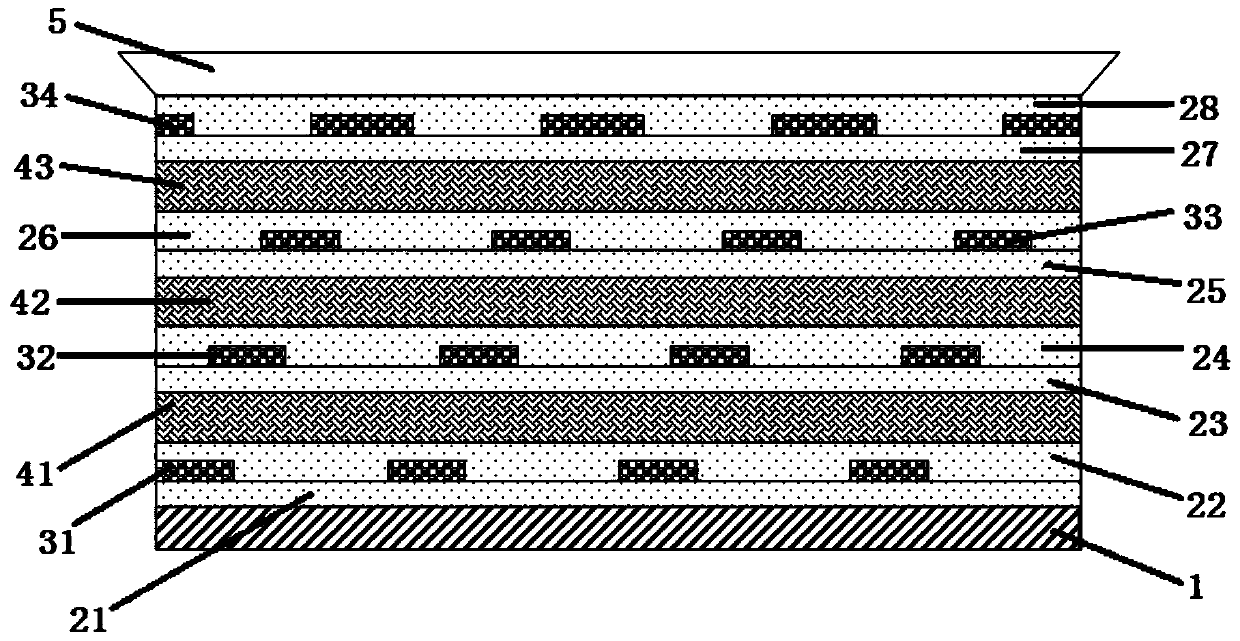

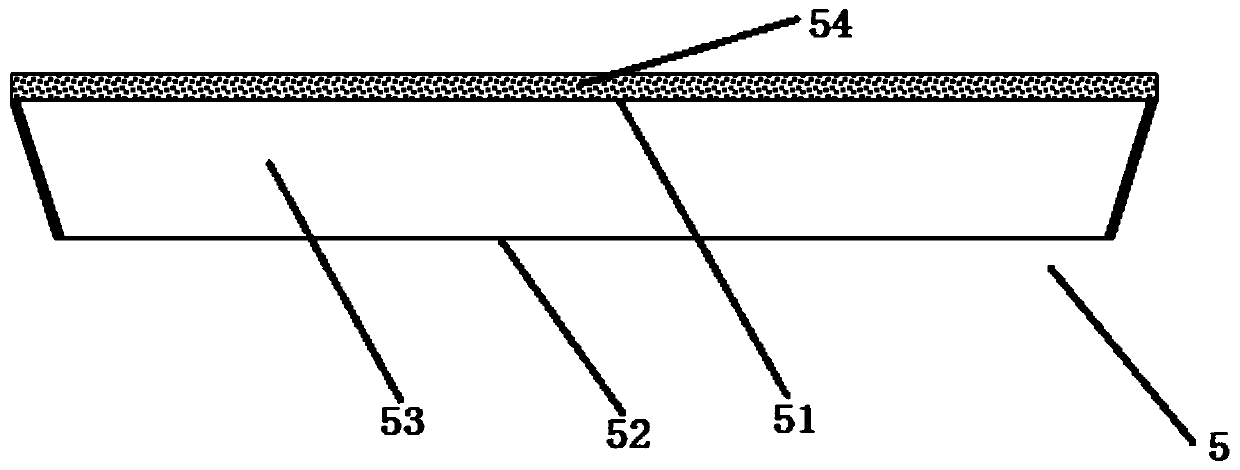

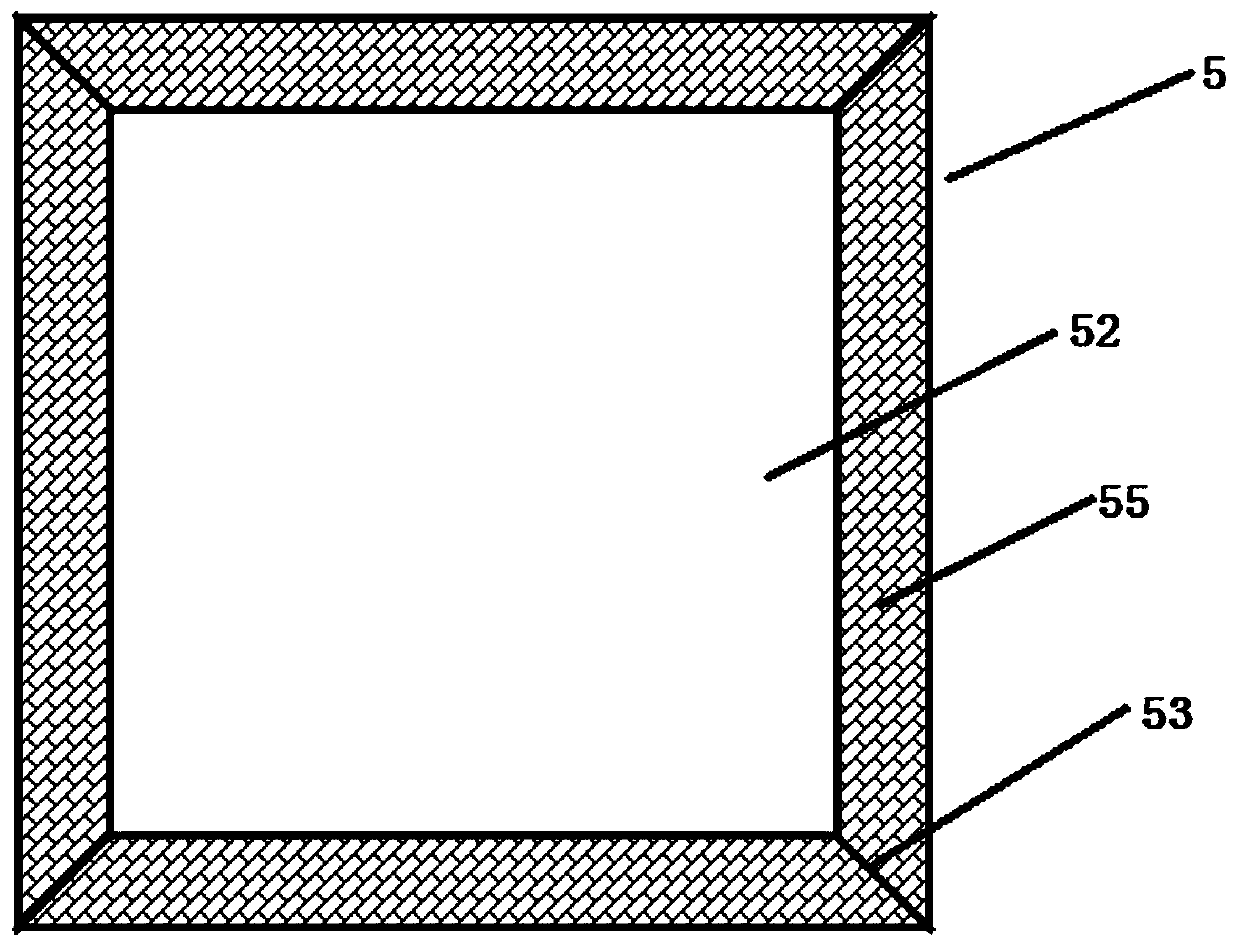

[0031] Such as figure 1 As shown, the present invention proposes a solar cell assembly, comprising: a solar cell backplane 1, a first EVA encapsulant layer 21 is laid on the solar cell backplane 1; a first solar cell layer, the first solar cell The cell layer is laid on the first EVA encapsulant layer 21, and the first solar cell layer includes a plurality of first cell sheets 31 in an array, between adjacent first cell sheets 31 in the lateral direction The ratio of the pitch to the width of the first battery sheet 31 is 2, and the distance between the adjacent first battery sheets 31 in the longitudinal direction is 1.5 millimeters; the second EVA packaging adhesive layer 22 is laid on the first On the solar cell sheet layer, the first scattering epoxy resin adhesive layer 41 is laid on the second EVA encapsulation adhesive layer 22, and the first scattering epoxy resin adhesive layer 41 includes 70 parts by weight of epoxy resin adhesive and 7 parts by weight of glass bead...

Embodiment 2

[0037] This embodiment provides another solar cell assembly. Compared with Embodiment 1, the only difference is that the ratio of the width of the first overlapping region to the width of the first cell sheet 31 is 0.3, and the second overlapping The ratio of the width of the area to the width of the second battery sheet 32 is 0.3, the ratio of the width of the third overlapping area to the width of the third battery sheet 33 is 0.3, and the width of the fourth overlapping area and The ratio of the width of the first battery slice 31 is 0.6, the length of the first, second, third, and fourth battery slices (31-34) is 156 millimeters, and the first, second, and fourth battery slices (31-34) are all 156 mm long. The widths of the three battery sheets (31-33) are all 20 mm, and the width of the fourth battery sheet 34 is 30 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com