Impregnation device for fabric setting machine

A technology of dipping device and setting machine, which is applied in the direction of fabric surface trimming, heating/cooling fabric, textile material processing, etc., can solve the problems of reduced traveling speed and affecting product setting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

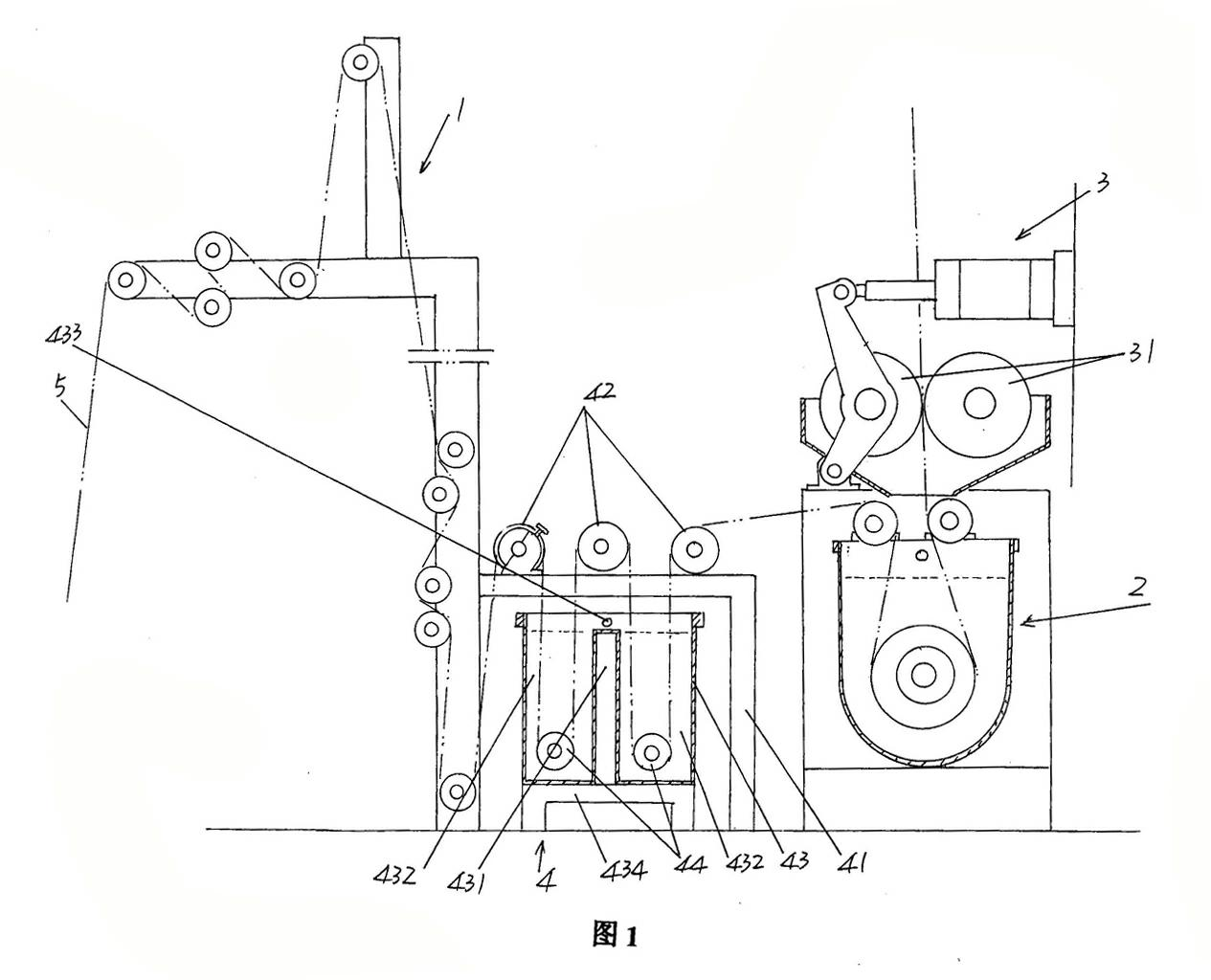

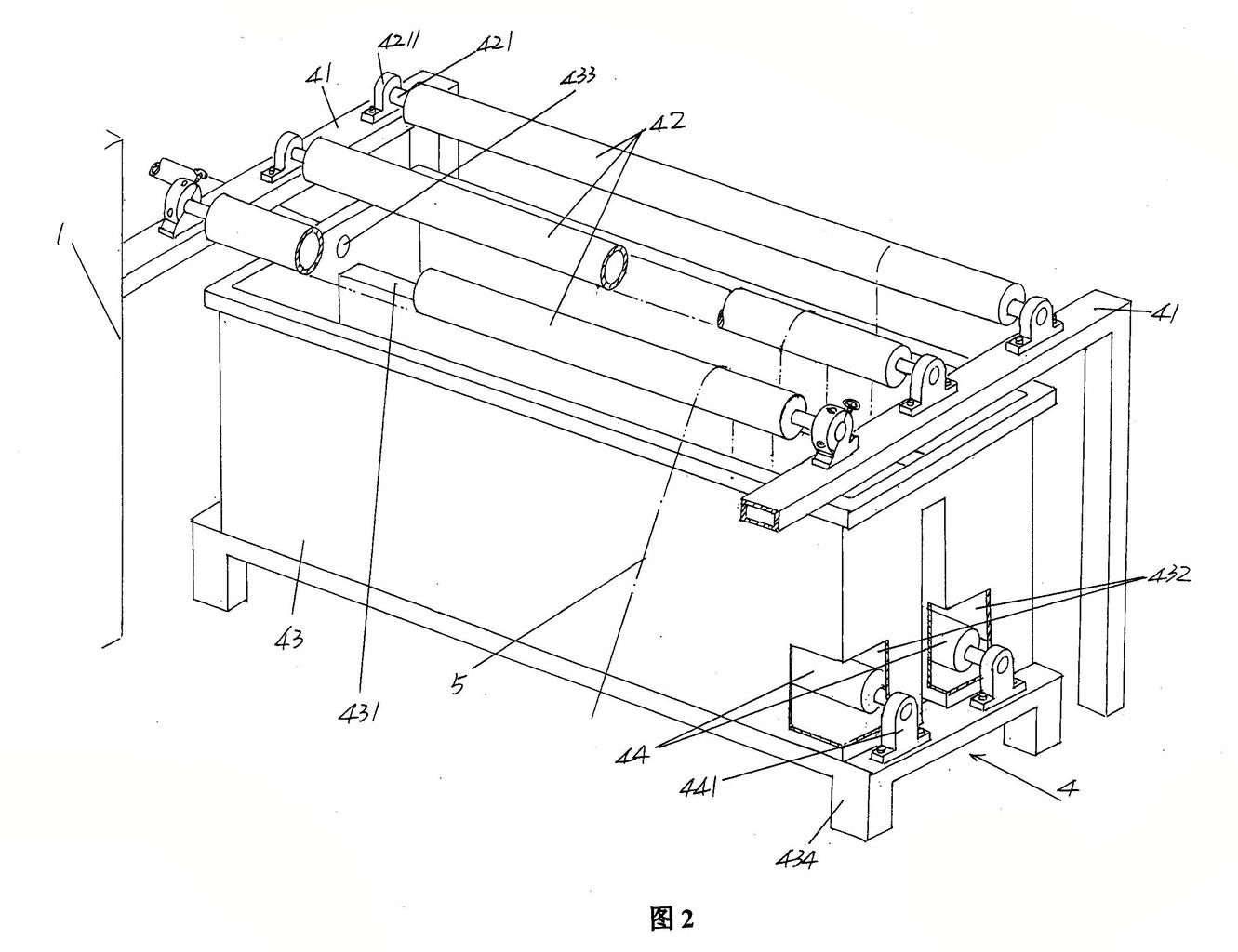

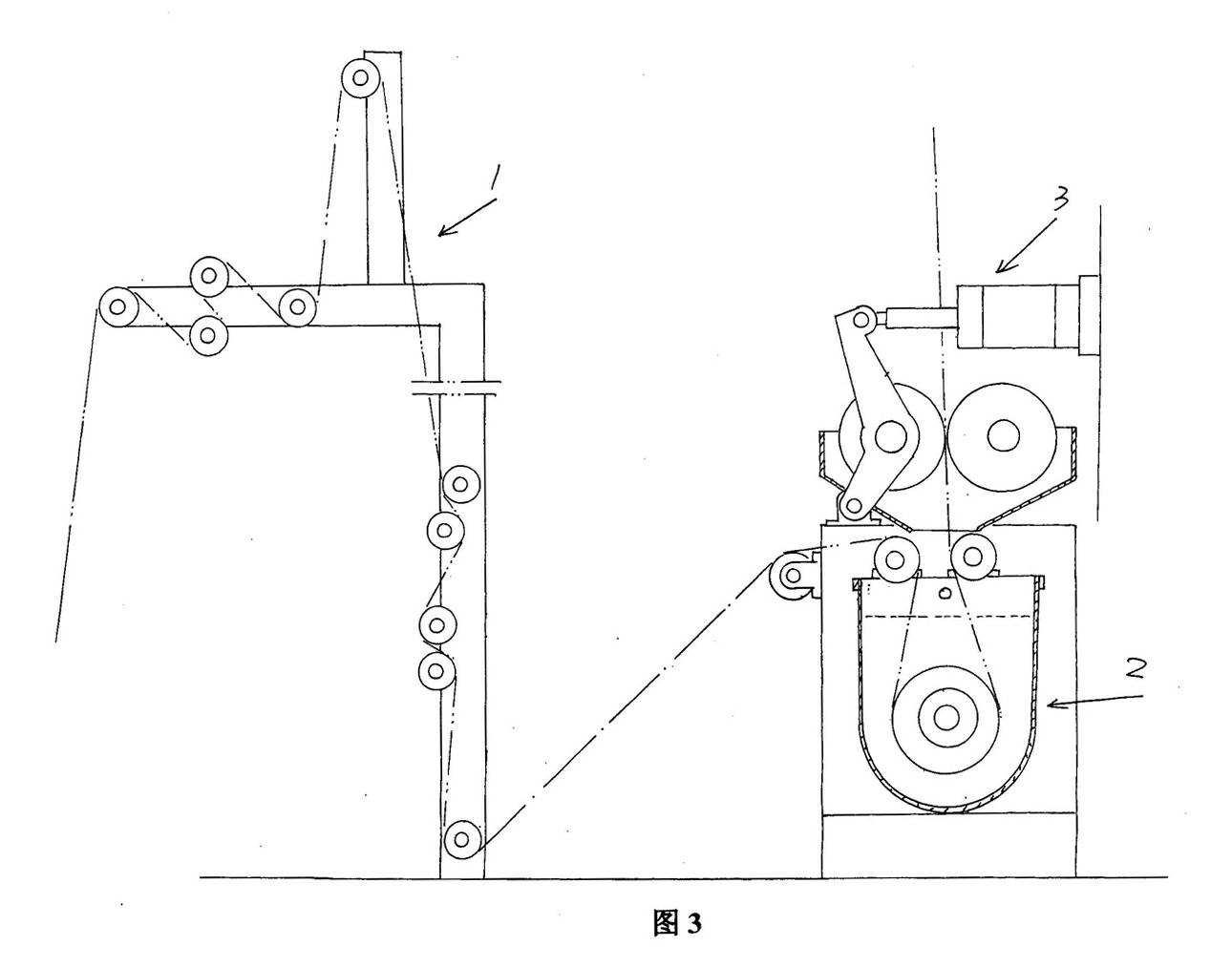

[0015] See figure 1 and figure 2 , due to the figure 1 The structures of the introduction mechanism 1, the dipping tank 2 and the liquid-displacement mechanism 3 provided above the dipping tank 2 belong to the known technology, so the applicant will not describe them again.

[0016] As the technical gist of the technical solution provided by the present invention, a pre-impregnation mechanism 4 as an impregnation device is added between the aforementioned introduction mechanism 1 and the impregnation tank 2, and the preferred but not absolutely limited pre-impregnation mechanism 4 includes a pair of each other Parallel brackets 41, three cloth guide rollers 42, a prepreg tank 43 and a pair of prepreg transition cloth guide rollers 44, a pair of brackets 41 are connected to the introduction mechanism 1, and the three cloth guide rollers 42 are spaced from each other and parallel to each other The rotation is arranged on a pair of brackets 41 , more precisely, the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com