Exhaust fan

A technology of exhaust fans and fan casings, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

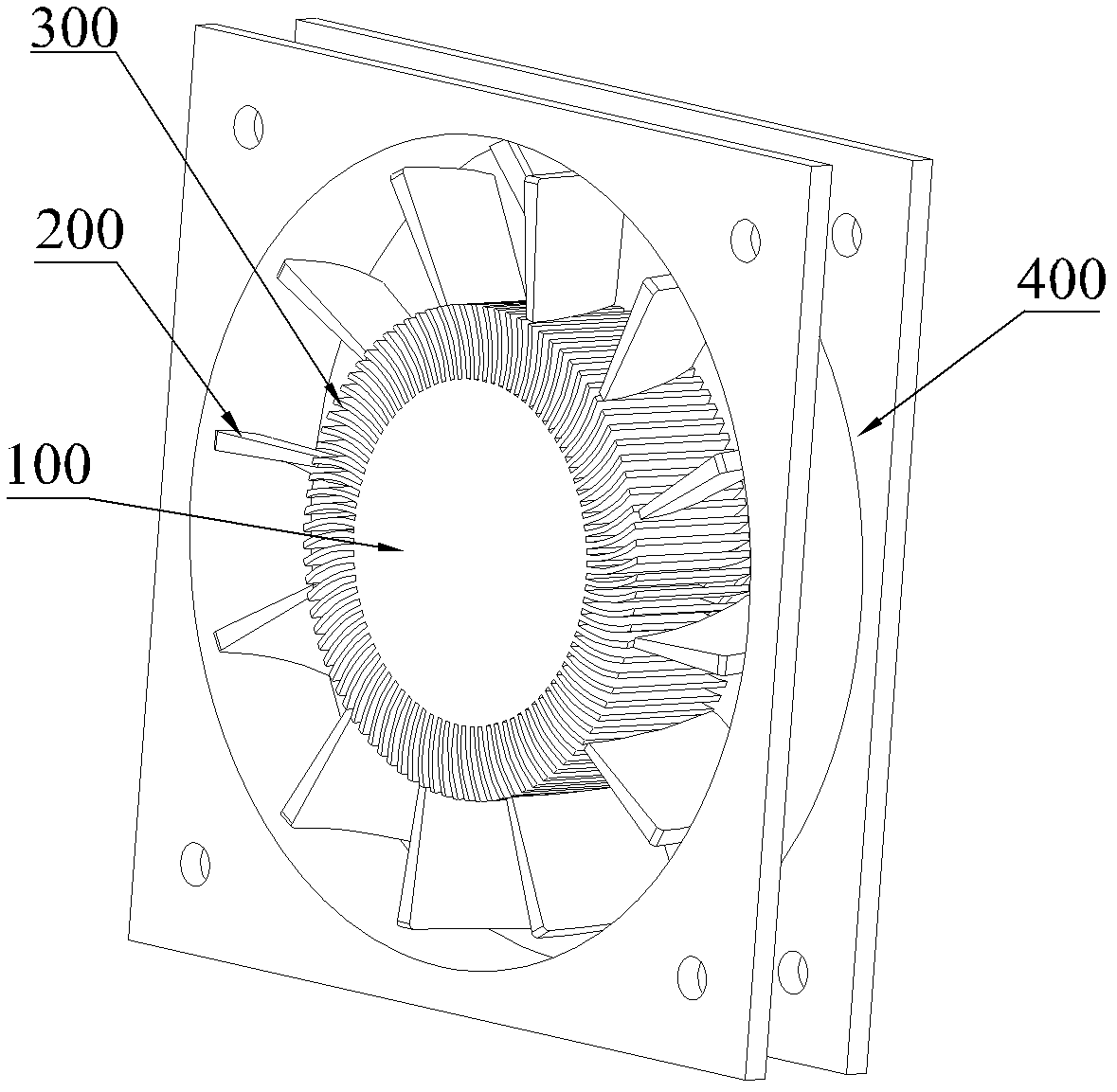

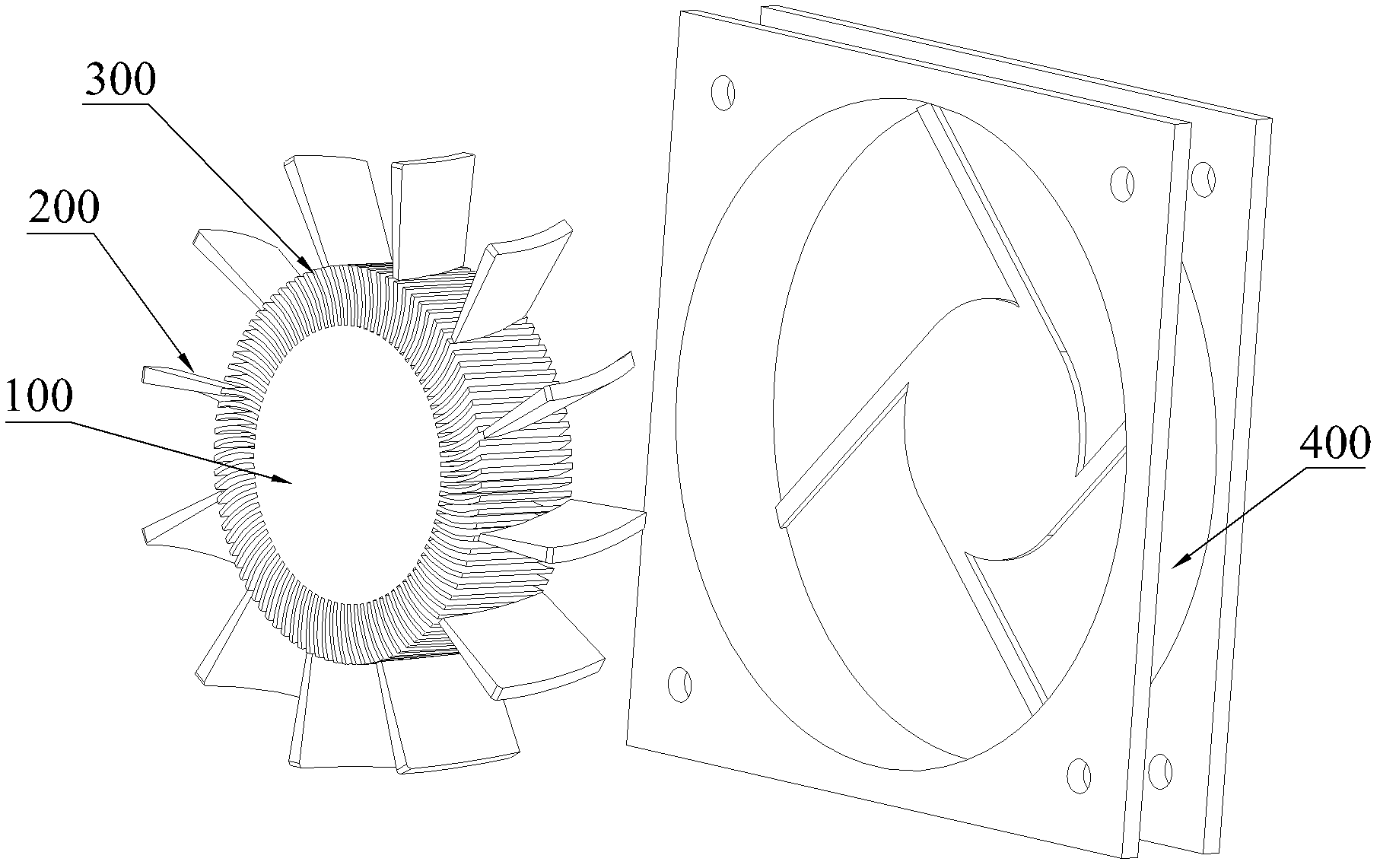

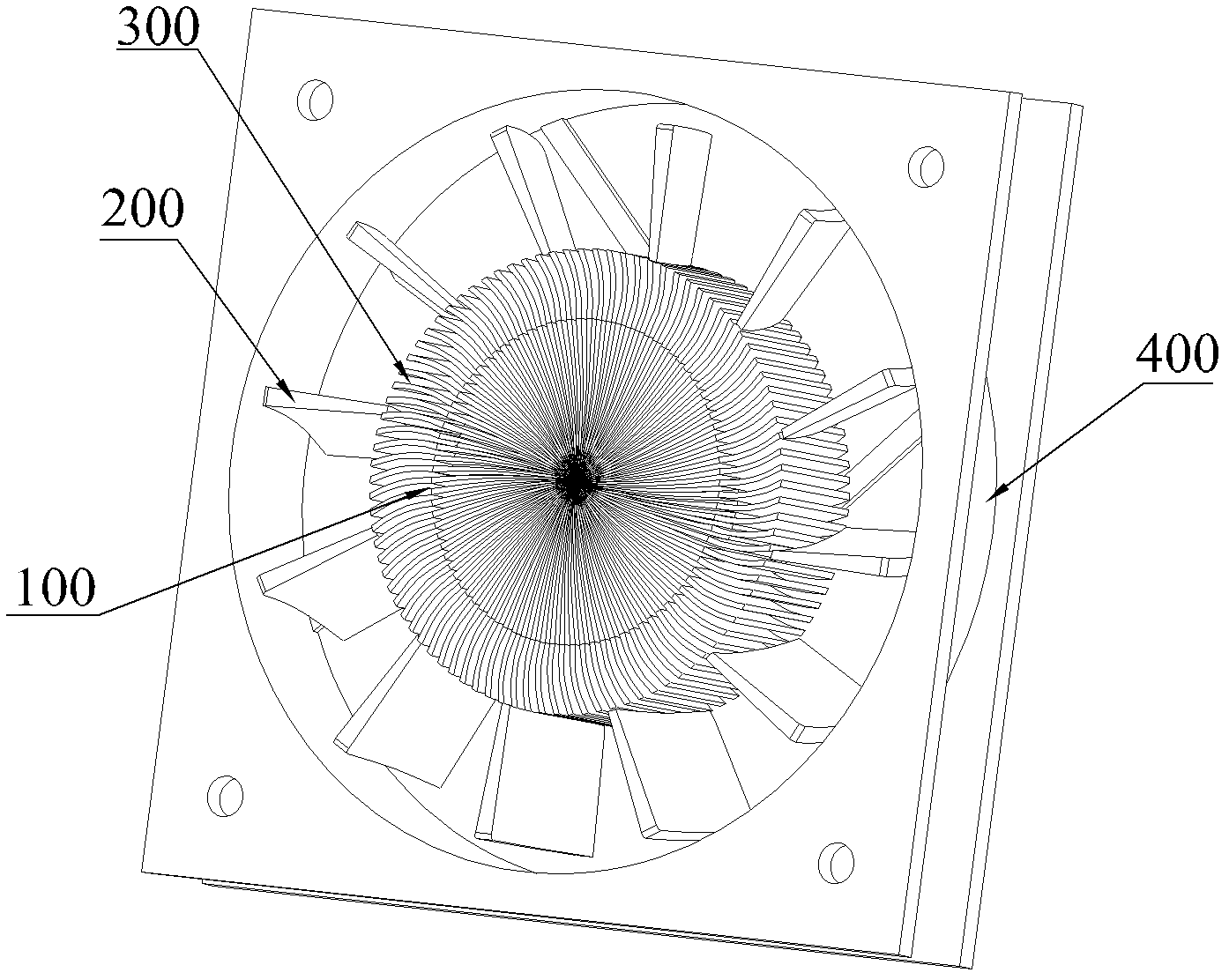

[0019] figure 1 It is a structural schematic diagram of an exhaust fan in an embodiment. figure 2 yes figure 1 An exploded view of the exhaust fan shown. The exhaust fan includes a shaft sleeve 100 , a first fan blade 200 , a second fan blade 300 and a fan case 400 .

[0020] The shaft sleeve 100 is used to be connected with the motor and driven to rotate by the motor.

[0021] There are multiple first fan blades 200 , all of which are arranged on the outer peripheral surface of the shaft sleeve 100 along the radial direction of the shaft sleeve 100 . The first fan blade 200 is an axial flow fan blade, which is used for sucking in air along the axial direction of the exhaust fan and blowing the air out along the axial direction of the exhaust fan to cool the components. In this embodiment, a plurality of first fan blades 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com