Method and device for measuring viscosity of high-temperature high-pressure fluid

A high-temperature, high-pressure, viscous technology, applied in the measurement of DC flow characteristics, etc., can solve problems such as the lack of hydrocarbon fuels, and achieve the effects of great flexibility, simple and convenient experimental operation, and improved measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

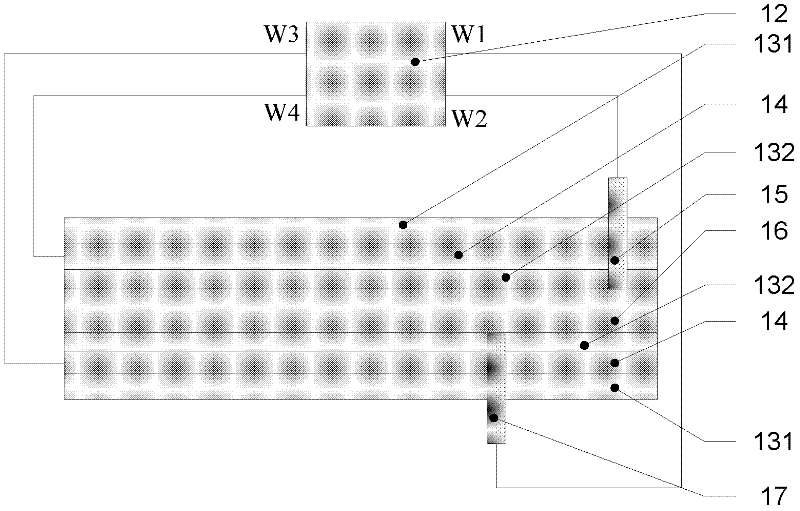

[0049] The invention is a device suitable for measuring the viscosity of high-temperature and high-pressure fluids, comprising three parts: a measuring system, a heating and heat preservation system and a data acquisition system.

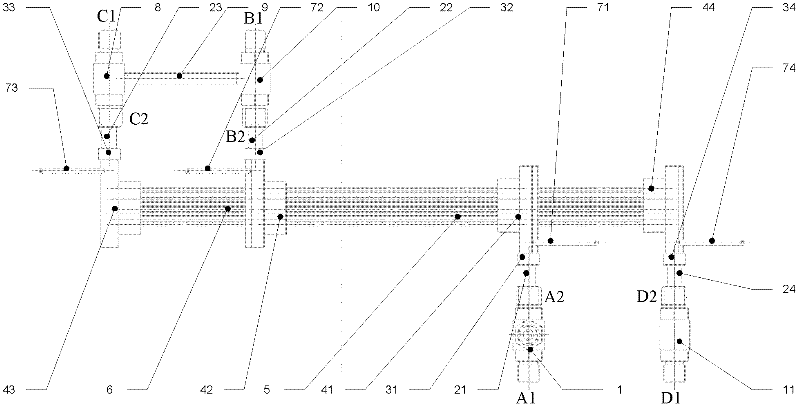

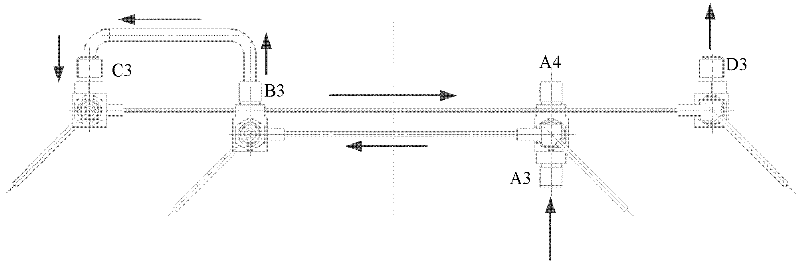

[0050] Such as figure 1 As shown, the measurement system is divided into a short tube measurement part and a long tube measurement part, and the short tube measurement part includes eight short tube test sections 5, a first header 41, a second header 42, a first adapter 31, a second An adapter 32, a first guide tube 21, a second guide tube 22, a four-way joint 1, a first three-way joint 10, a first pressure-taking tube 71 and a second pressure-taking tube 72;

[0051] A guide tube 9 is used for connection between the short tube measurement part and the long tube measurement part. The device must be used horizontally to eliminate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com