Method for detecting adhesiveness of film based on surface wave

A technology of film adhesion and detection method, applied in the direction of material excitation analysis, etc., can solve the problems of inability to achieve quantitative film adhesion and film damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

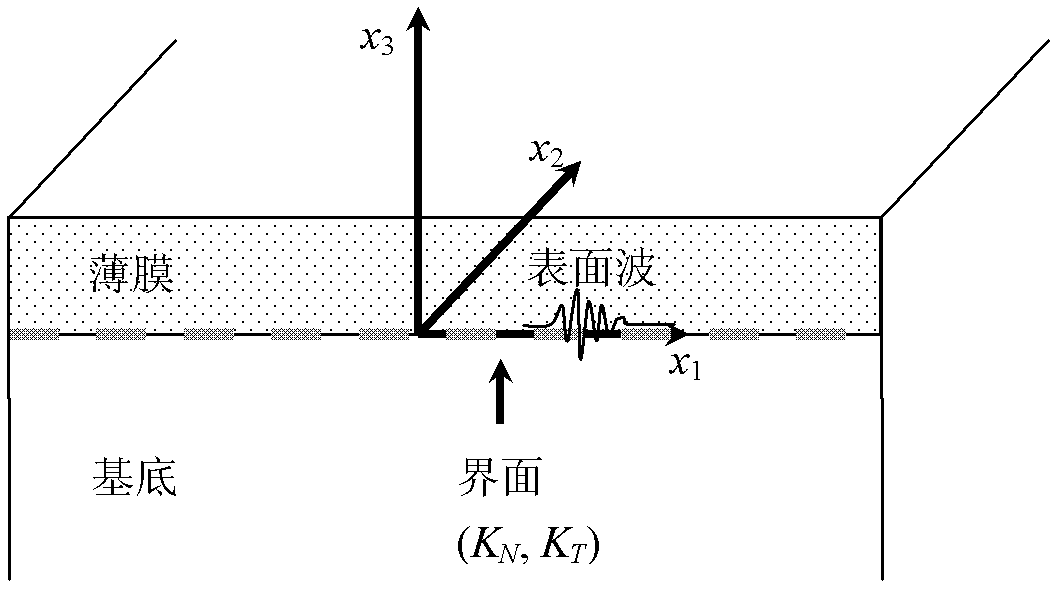

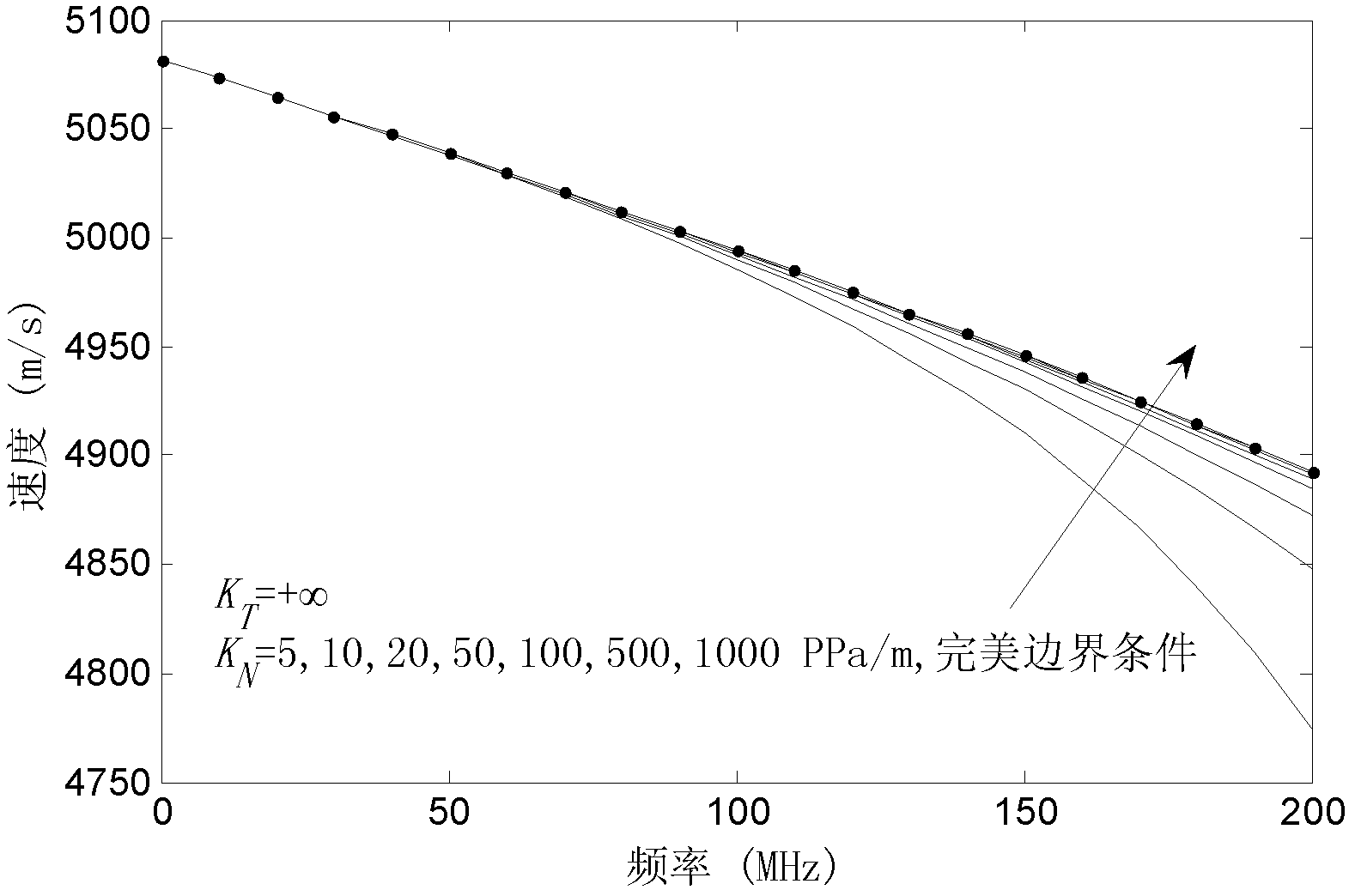

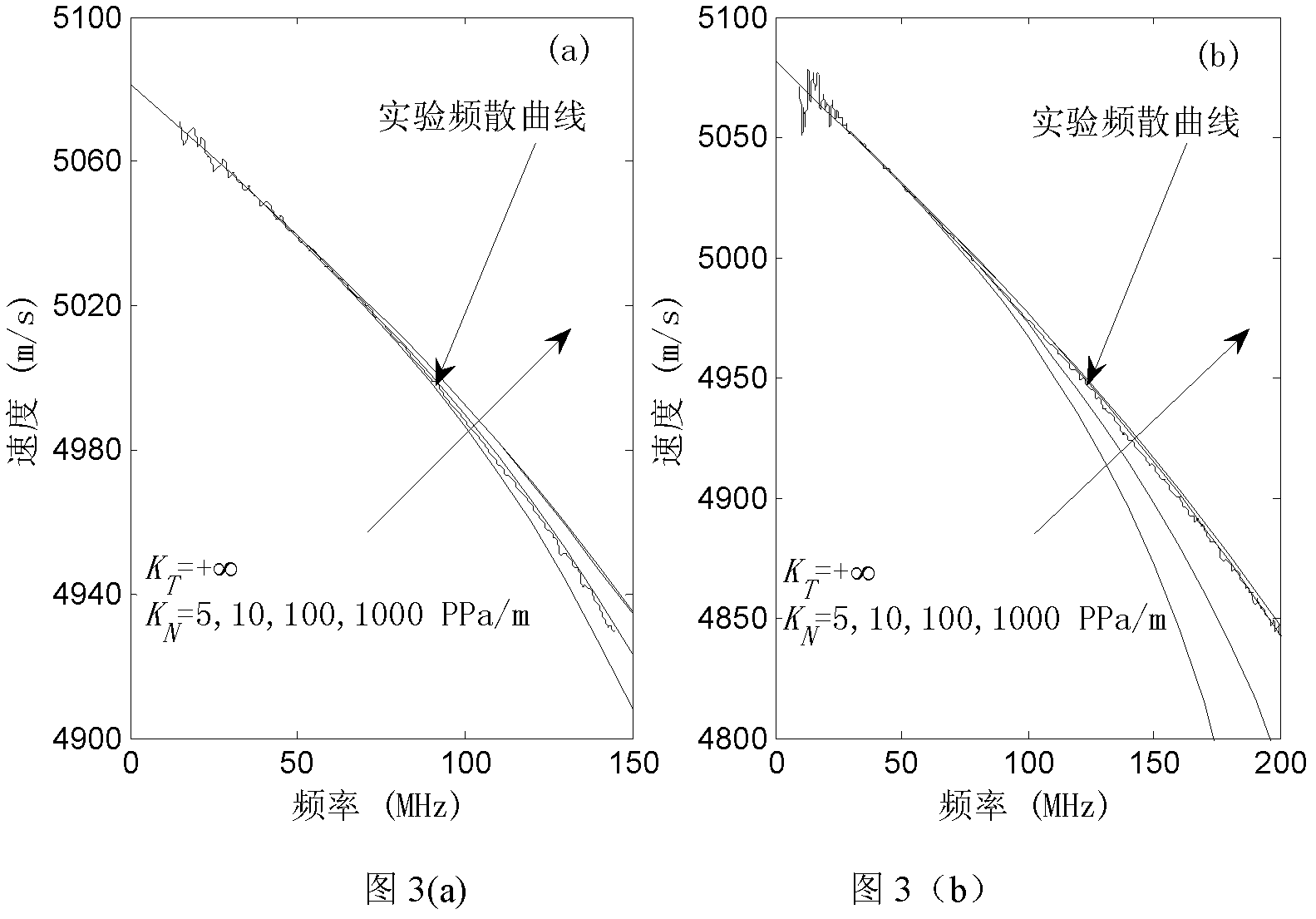

[0022] The invention uses a short-pulse laser source to excite surface wave signals with a relatively large spectral width on the surface of a sample. The surface wave signal is collected by a piezoelectric detector. Calculation by software programming with different normal elastic coefficients (K N ) surface wave dispersion curve. Match the surface wave dispersion curve obtained by the experiment with the dispersion curve obtained by theoretical calculation, so as to determine the K of the interface between the sample film and the substrate. N value, and use this value as a parameter to characterize the film / substrate adhesion. The present invention will be described in detail below.

[0023] When the surface wave propagates in the film / substrate structure, dispersion occurs, that is, the phase velocity of the surface wave varies with frequency. In theory, the dispersion curve of a surface wave can be obtained by solving the wave equation for surface wave propagation in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com