Optical coupler

An optocoupler, photosensitive technology, applied in optocoupler, optocoupler. , In the field of photoelectric isolators or photocouplers, it can solve the problems of high precision requirements of lead frames, difficult process realization, and high insulation withstand voltage. It is easy to control the CTR value, high photoelectric conversion efficiency, and excellent insulation withstand voltage. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

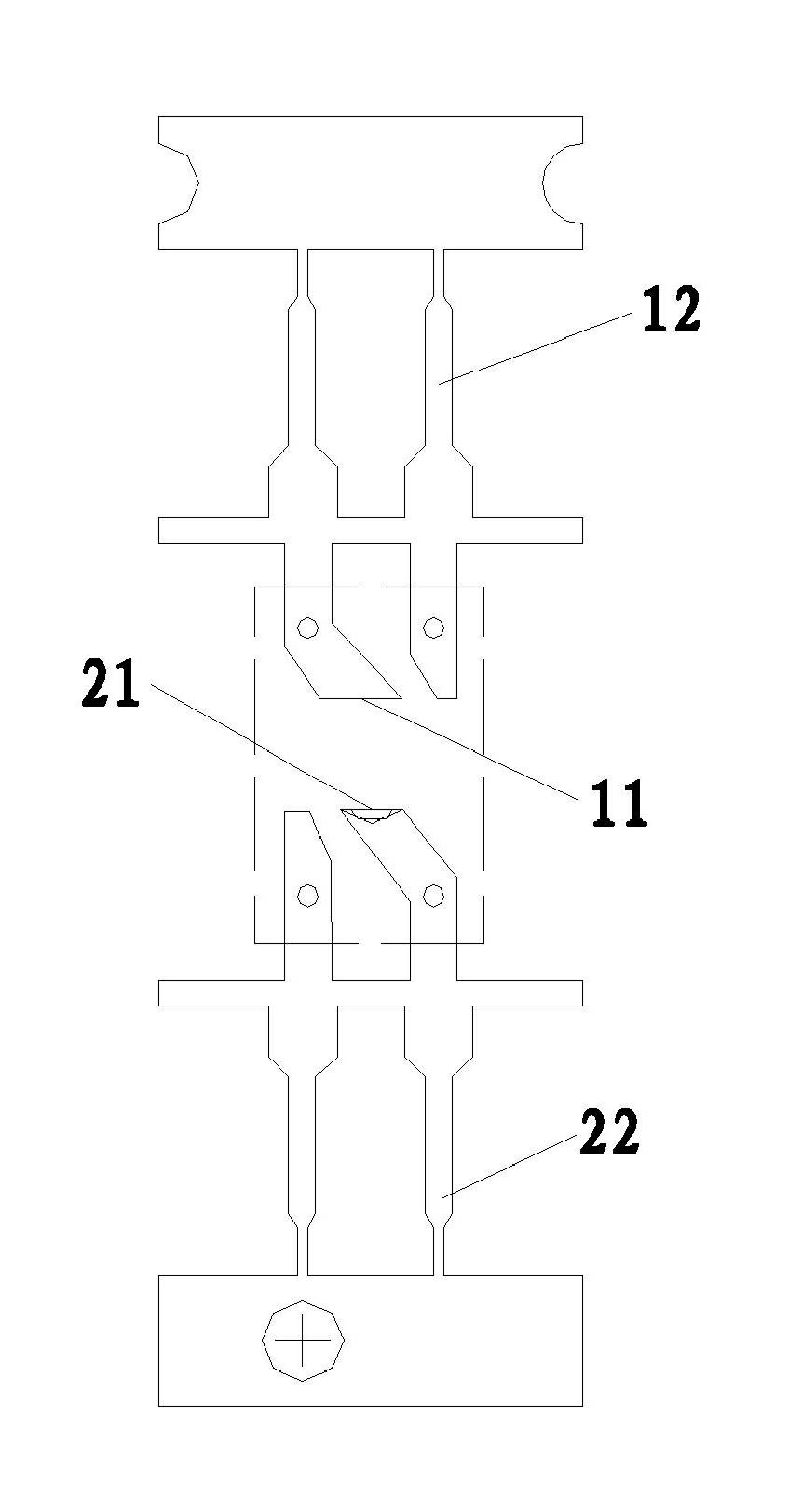

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments. Although the chip-loading area of the infrared end lead frame and the chip-loading area of the photosensitive end lead frame in the claims of the present invention can be cup-shaped or plane, the following examples only use the chip-loading area of the infrared end lead frame as a cup shape, and the photosensitive end lead The slide-loading area of the frame is described as a flat surface.

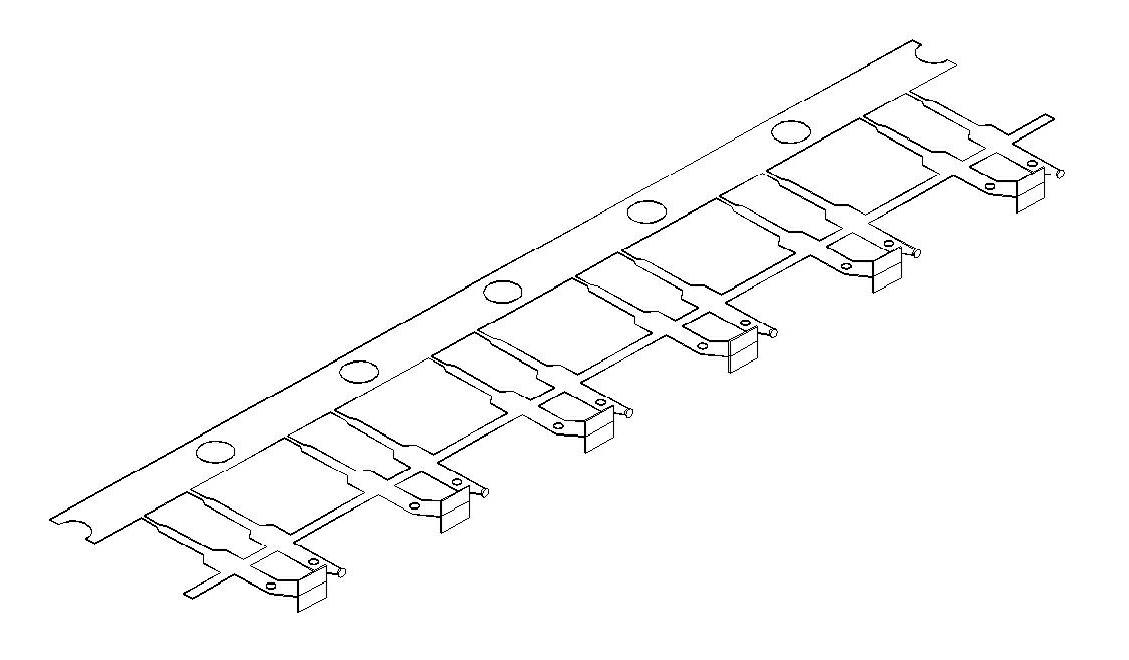

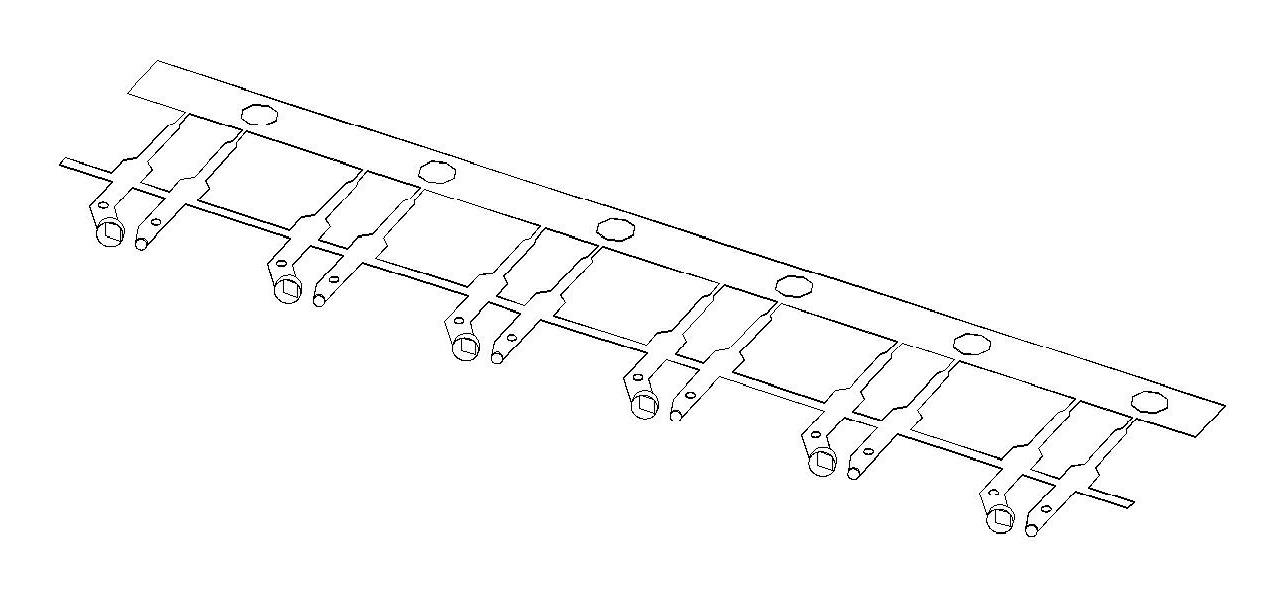

[0026] refer to figure 1 and figure 2 As shown, the lead frame of the optocoupler is divided into an infrared end lead frame 2 and a photosensitive end lead frame 1, and a plurality of infrared end lead frame units or photosensitive end lead frame units form a row of infrared end lead frames or photosensitive end lead frames. After the package is manufactured, the lead frame pins are punched to separate them into independent components.

[0027] For th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com