Connecting structure for brush holder assembly and rear end cover of motor

A technology of connecting structure and rear end cover, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of not being able to install screws at one time, prolong product assembly time, increase workload, etc., so as to reduce product assembly time, The installation structure is stable and reliable, and the production efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

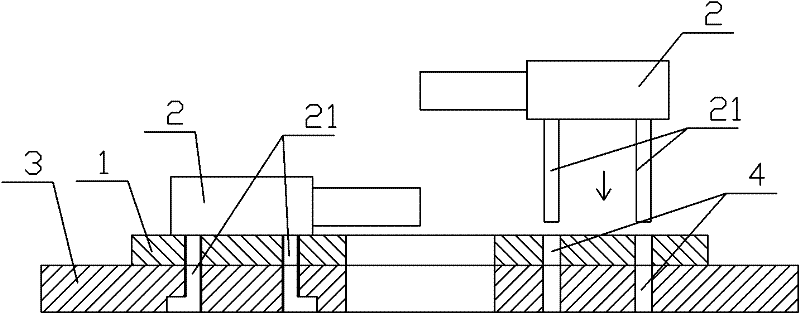

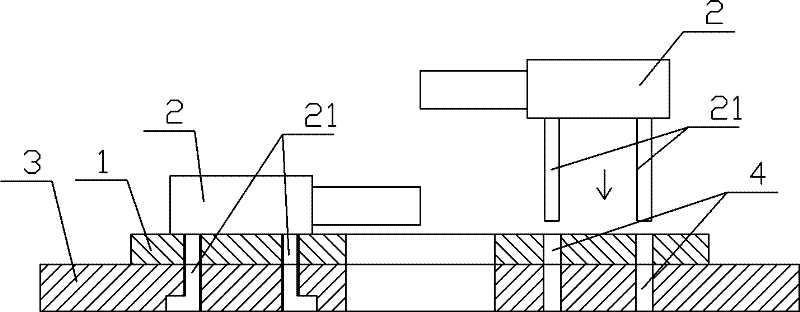

[0009] like figure 1 2 and 3, it is the connection structure of the brush holder assembly and the rear end cover of the motor of the present invention, including the brush holder plate 1, the brush holder 2 with pins 21 and the motor rear end cover 3. The number of pins is 2 to 4. The brush holder board and the motor rear end cover are provided with pin sockets 4. The pins of the brush holder pass through the pin holes on the brush holder board and the motor rear end cover. The frame 2, the brush frame plate 1 and the motor rear end cover 3 are riveted together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com