More readily available traction battery

一种电池、电池极的技术,应用在电池/电池的牵引、二次电池、气候可持续性等方向,能够解决不能实现可用性电池系统等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

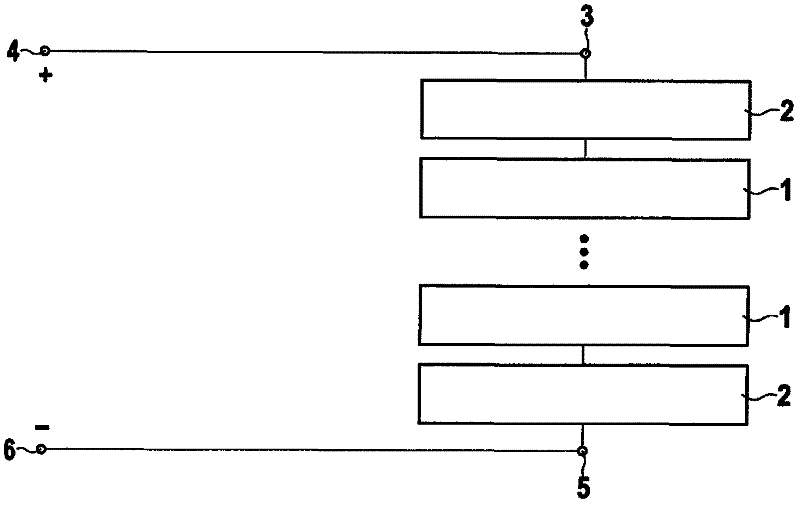

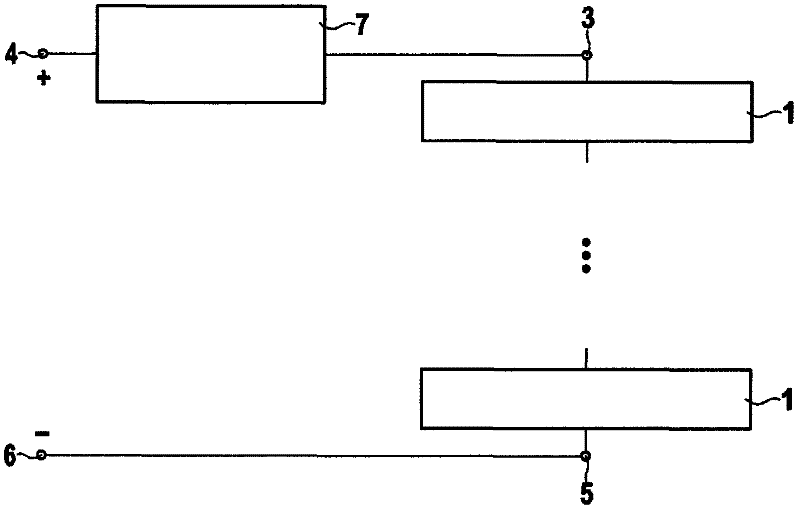

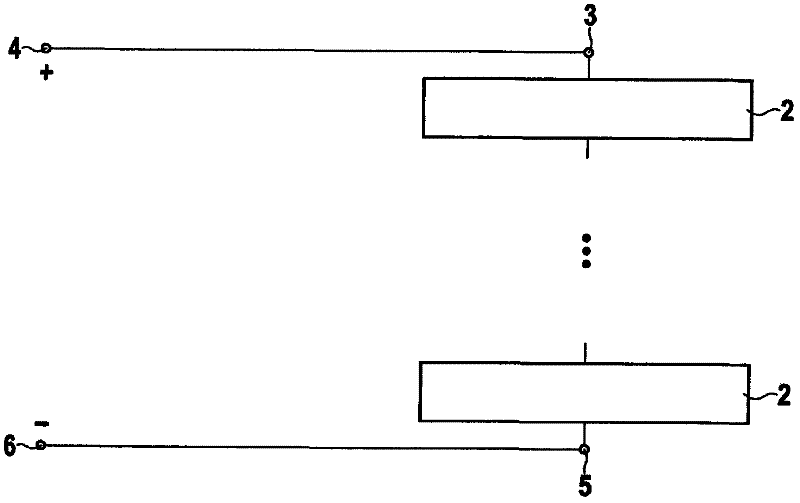

[0035] Preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings.

[0036] First, define the concepts "reliability" and "availability" in the sense used here (according to Lauber / "Prozessautomatisierung" 1st and 3rd editions, Springer Verlag):

[0037] "Reliability" is the ability of a system to work correctly for a predetermined time (also called reliability).

[0038] Availability is the probability that a serviceable system is in a working state for a predetermined point in time.

[0039] Therefore high availability can be improved by:

[0040] High reliability of the system

[0041] Short maintenance times (if the system is not in operation during the maintenance time) or (if possible) through maintenance without interruption of operation.

[0042]According to the invention, the availability of the battery system is increased compared to the prior art, since the failure of individual battery cells does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com