Progressive die molding process for arc-shaped sheet metal component with U-shaped cross-section

A forming process and technology of sheet metal parts, applied in the field of progressive die forming process of U-section curved sheet metal parts, can solve the problems of high labor intensity, low processing precision, high manufacturing and processing cost, reduce labor intensity, The effect of ensuring molding quality and reducing auxiliary man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

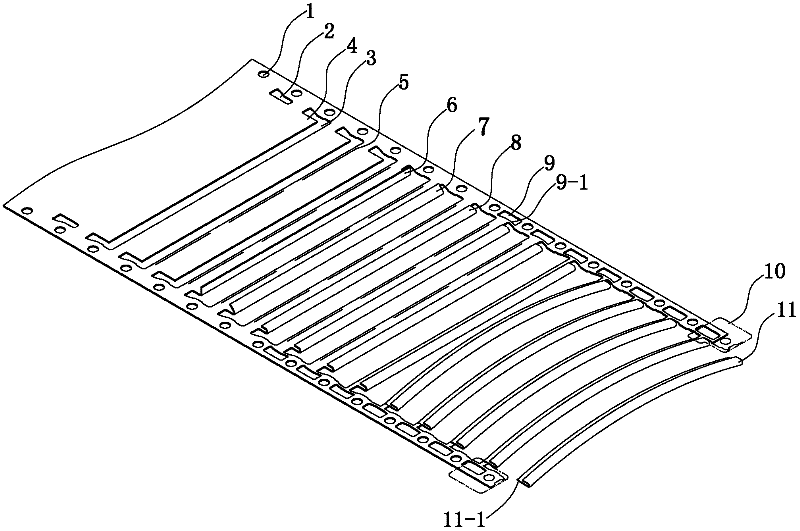

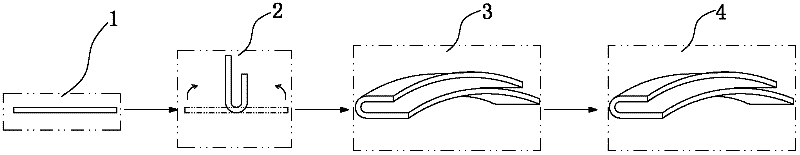

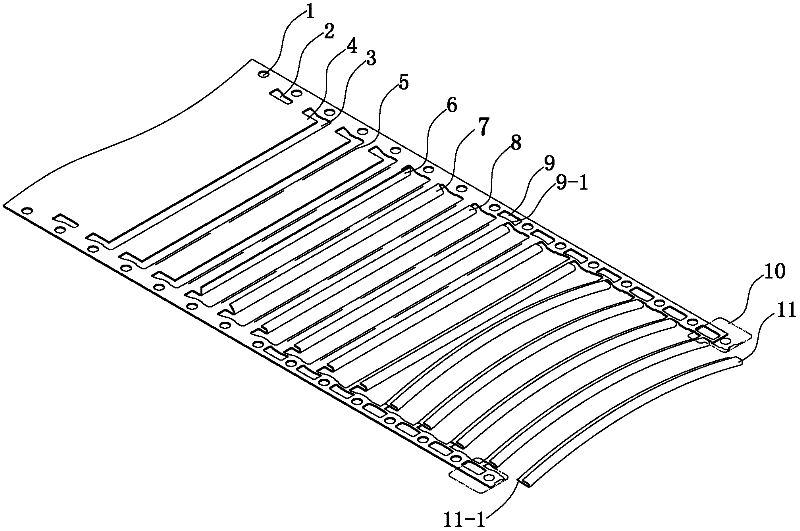

[0027] see figure 1 , a progressive mode forming process for U-shaped cross-section arc-shaped sheet metal parts, including the following processes:

[0028] 1) Place the plate on the workbench, and punch out the positioning hole 1 at its longitudinal position close to the edge;

[0029] 2) Taking the above positioning hole as the positioning reference, punch the lateral boundary hole 2 inside the positioning hole, and the distance between the inner surfaces of the lateral boundary holes on both sides is consistent with the length of the sheet metal part before arc pressing;

[0030] 3) Taking the above positioning hole as the positioning reference, punching the longitudinal hole 3 connecting the right ends of the two transverse boundary hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com