Hydraulic jack

A hydraulic jack and high-pressure technology, applied in the direction of lifting devices, etc., can solve the problems of restricting the range of use of the jack, and the jack cannot be used upside down or flat, achieving the effect of strong adaptability and expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

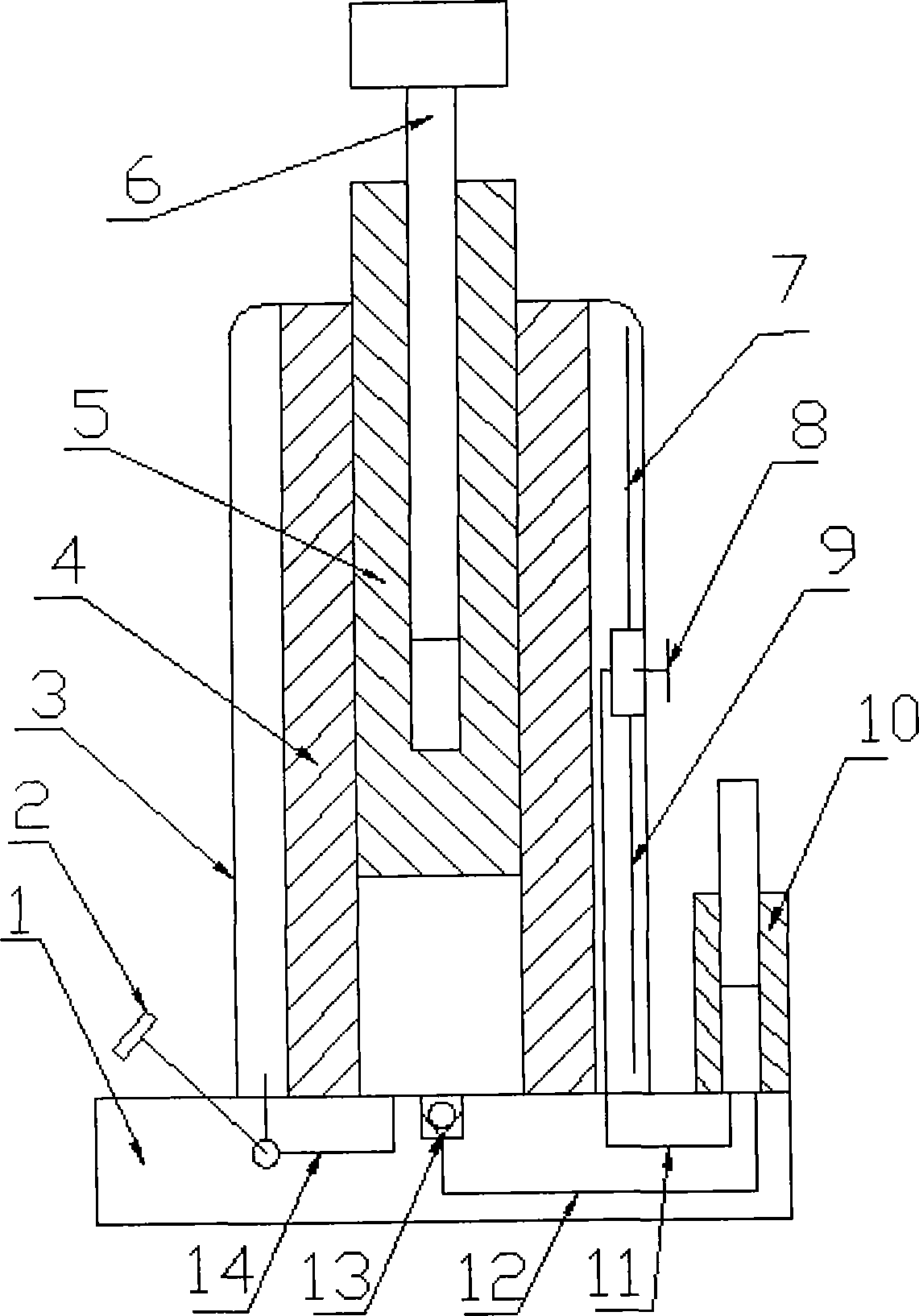

[0009] The total oil suction pipe (11), high-pressure passage (12), and oil discharge passage (14) in the present invention are pre-set on the base (1), and the one-way valve (13) is arranged at the outlet end of the high-pressure passage (12), Install and fix the piston (4) on the base (1), align the center of the piston (4) with the one-way valve (13), and install a three-way valve (8) in the middle of the oil tank (3) , the conversion handle of the three-way valve (8) is outside the fuel tank (3), connect the oil suction pipe A (7) and the oil suction pipe B (9) to the three-way valve (8) respectively, and make the oil pipe A (7) and The ports of the oil suction pipe B (9) are respectively placed at the bottom and top of the fuel tank (3), and the two ends of the main oil suction pipe (11) are respectively connected to one of the channels of the manual hydraulic pump (10) and the three-way valve (8) , the piston (5) is installed in the cylinder of the piston cylinder (4), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com