Synchronous denitrification and dephosphorization bio-filter packing and preparation method thereof

A simultaneous denitrification and phosphorus removal and biological filter technology, applied in the field of simultaneous denitrification and phosphorus removal biological filter filler and its preparation, can solve the problems of denitrification and phosphorus removal water treatment technology and functional materials to be developed, and reach the load capacity Large size, reduced production cost, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the filler for the simultaneous denitrification and dephosphorization biological filter is prepared according to the following method:

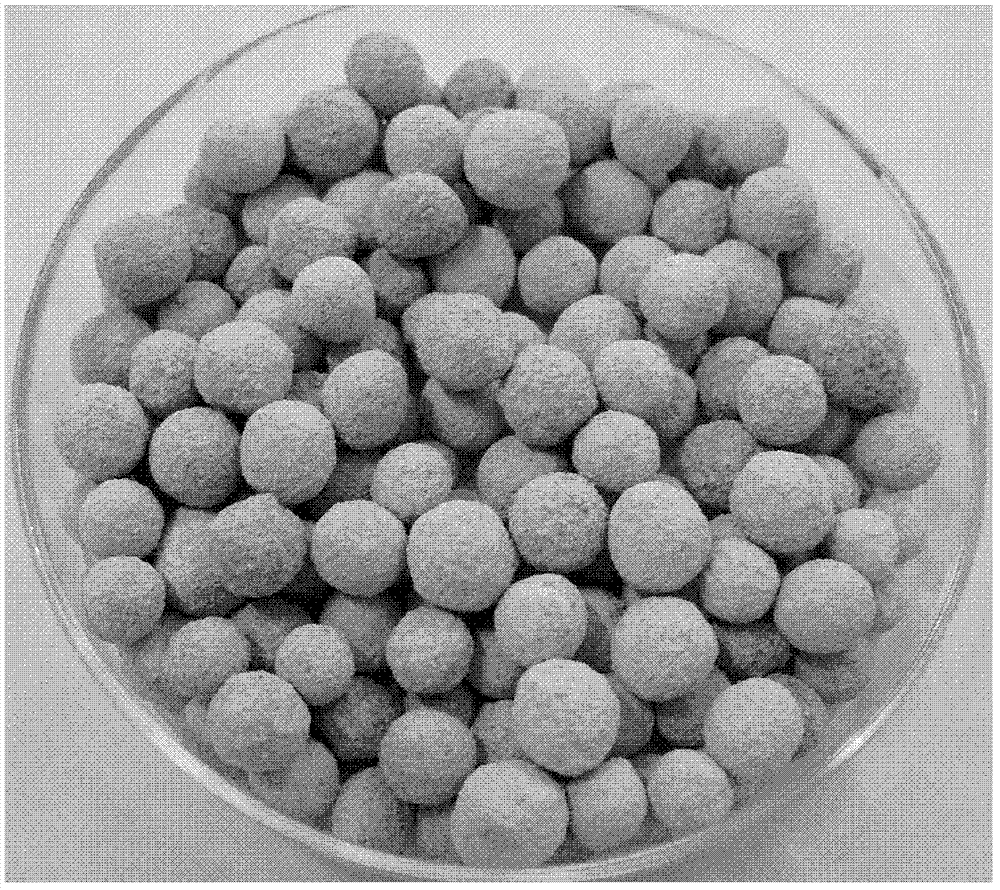

[0030] Clinoptilolite ore is crushed to obtain 30-80 mesh zeolite powder, 600g zeolite powder and 200g No. 425 cement are added to the mixer and mixed for 30 minutes, so that the two raw materials are mixed evenly to obtain a mixture; the mixture is evenly sprinkled into In the ball forming plate, the ball forming plate rotates at a speed of 5 revolutions per minute. While spreading the mixture, spray water evenly on the mixture in the ball forming plate to make the mixture roll into spherical particles. The amount of water sprayed is related to the quality of the mixture. The ratio is 1:1. As the particles roll in the ball forming disk, the diameter of the particles increases continuously until the particle diameter reaches 3-5mm. The particles are discharged from the ball forming disk, and then the prepared spheric...

Embodiment 2

[0032] In this embodiment, the filler for the simultaneous denitrification and dephosphorization biological filter is prepared according to the following method:

[0033] Clinoptilolite ore is crushed to obtain 30-80 mesh zeolite powder, 500g zeolite powder and 500g No. 425 cement are added to the mixer and mixed for 30 minutes, so that the two raw materials are mixed evenly to obtain a mixture; the mixture is evenly sprinkled into In the ball forming plate, the ball forming plate rotates at a speed of 50 revolutions per minute. While spreading the mixture, spray water evenly on the mixture in the ball forming plate to make the mixture roll into spherical particles. The amount of water sprayed and the quality of the mixture The ratio is 2:1. As the particles roll in the ball forming disk, the particle diameter increases continuously until the particle diameter reaches 4-6mm. The particles are discharged from the ball forming disk, and then the prepared spherical particles are p...

Embodiment 3

[0035] In this embodiment, the filler for the simultaneous denitrification and dephosphorization biological filter is prepared according to the following method:

[0036] Clinoptilolite ore is crushed to obtain 30-80 mesh zeolite powder, 200g zeolite powder and 800g No. 425 cement are added to the mixer and mixed for 30 minutes, so that the two raw materials are mixed evenly to obtain a mixture; In the ball forming plate, the ball forming plate rotates at a speed of 100 revolutions per minute. While spreading the mixture, spray water evenly on the mixture in the ball forming plate to make the mixture roll into spherical particles. The amount of water sprayed is related to the quality of the mixture. The ratio is 1:2. As the particles roll in the ball forming disk, the particle diameter increases continuously until the particle diameter reaches 6-8mm. The particles are discharged from the ball forming disk, and then the prepared spherical particles are piled up. Moisturize and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com