High glowing filament flame-retardant PA (polyamide)/PPO (polyphenyleneoxide) alloy and preparation method thereof

A high-glow wire and alloy technology, applied in the field of polymer materials, can solve the problems that cannot meet the requirements of glow wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

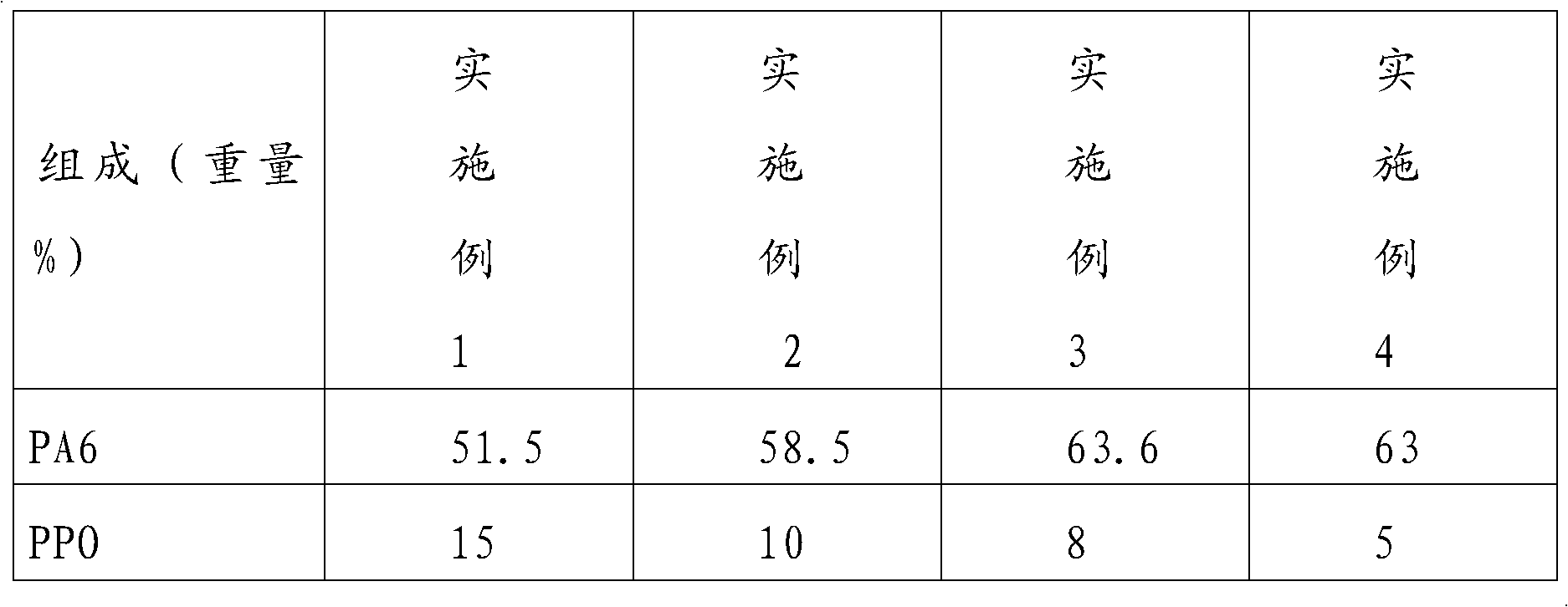

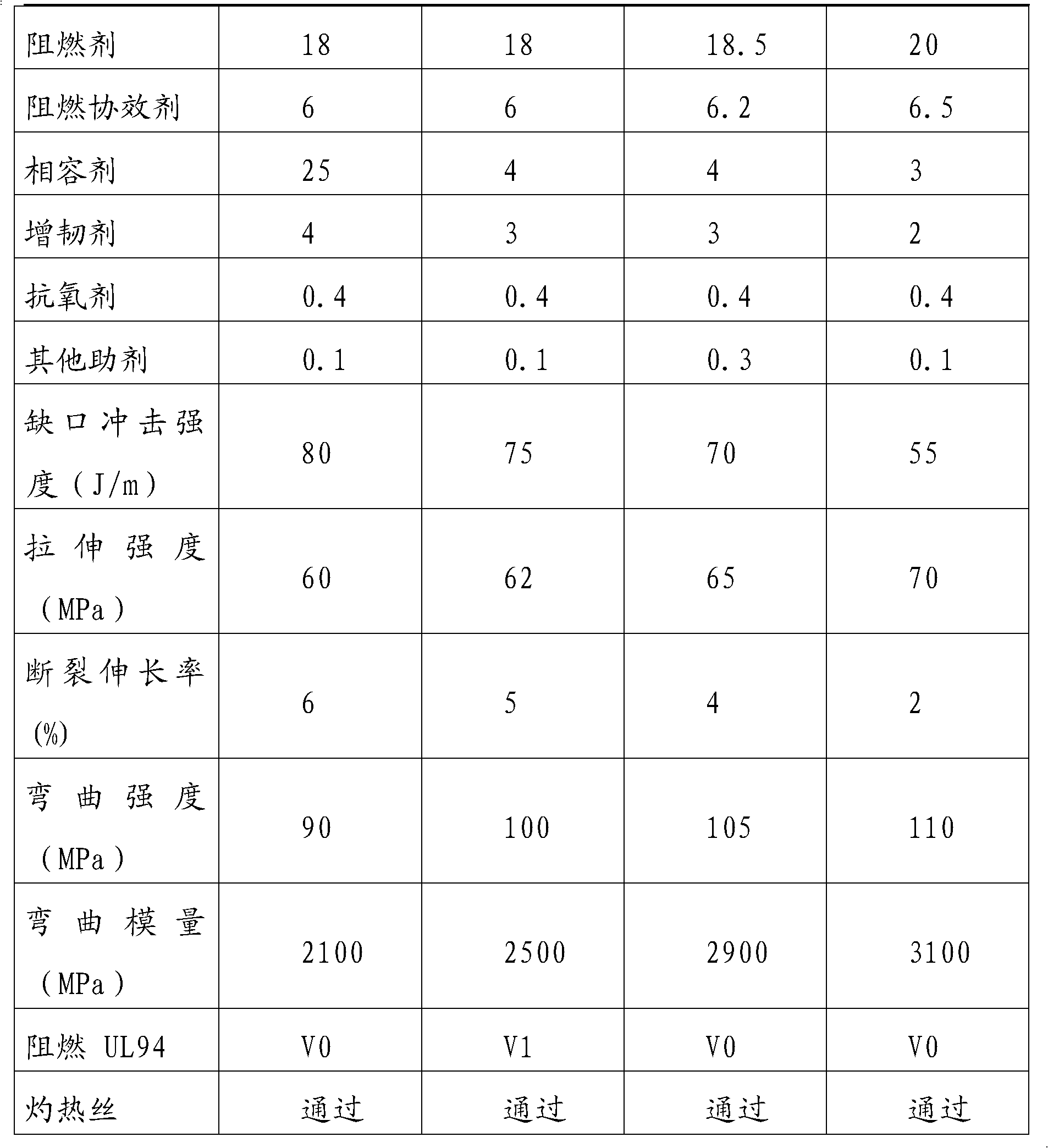

Embodiment 1

[0035] PA6 51.5% (weight percentage, the same below), PPO 15%, flame retardant 18%, flame retardant synergist 6%, compatibilizer 5%, toughening agent 4%, antioxidant 1010 / 168 0.2 / 0.2 %, other additives 0.1%.

[0036] Preparation method: first dry PA6, PPO and toughening agent in a vacuum drying oven at 80°C for 4 to 8 hours, weigh the dried PA6, PPO resin and various additives according to the proportion, and put all the raw materials into the The feeding hopper of the twin-screw extruder is melt-extruded and granulated; the processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 140-180°C, the temperature of the second zone is 190-220°C, and the temperature of the third zone is 220-230°C. The temperature in the fourth zone is 230-250°C, the head is 180-220°C, the residence time is 2-3min, the pressure is 12-18MPa, and the screw speed is 130-150 rpm.

Embodiment 2

[0038] PA6 58.5% (weight percentage, the same below), PPO 10%, flame retardant 18%, flame retardant synergist 6, compatibilizer 4%, toughening agent 3%, antioxidant 1010 / 168 0.2 / 0.2% , Other additives 0.1%.

[0039] Preparation method: first dry PA6, PPO and toughening agent in a vacuum drying oven at 80°C for 4 to 8 hours, weigh the dried PA6, PPO resin and various additives according to the proportion, and put all the raw materials into the The feeding hopper of the twin-screw extruder is melt-extruded and granulated; the processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 140-180°C, the temperature of the second zone is 190-220°C, and the temperature of the third zone is 220-230°C. The temperature in the fourth zone is 230-250°C, the head is 180-220°C, the residence time is 2-3min, the pressure is 12-18MPa, and the screw speed is 130-150 rpm.

Embodiment 3

[0041] PA6 63.6% (weight percentage, the same below), PPO 8%, flame retardant 18.5%, flame retardant synergist 6.2, compatibilizer 4%, toughening agent 3%, antioxidant 1010 / 168 0.2 / 0.2% , Other additives 0.3%.

[0042] Preparation method: first dry PA6, PPO and toughening agent in a vacuum drying oven at 80°C for 4 to 8 hours, weigh the dried PA6, PPO resin and various additives according to the proportion, and put all the raw materials into the The feeding hopper of the twin-screw extruder is melt-extruded and granulated; the processing technology is as follows: the temperature of the first zone of the twin-screw extruder is 140-180°C, the temperature of the second zone is 190-220°C, and the temperature of the third zone is 220-230°C. The temperature in the fourth zone is 230-250°C, the head is 180-220°C, the residence time is 2-3min, the pressure is 12-18MPa, and the screw speed is 130-150 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com