Temperature-pH dual-sensitivity gel microsphere as well as preparation method and application thereof

A technology of gel microspheres and ambidextrous, which is applied in the direction of immobilization on/in the organic carrier, which can solve the problems of cumbersome operation and inability to achieve synchronous immobilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

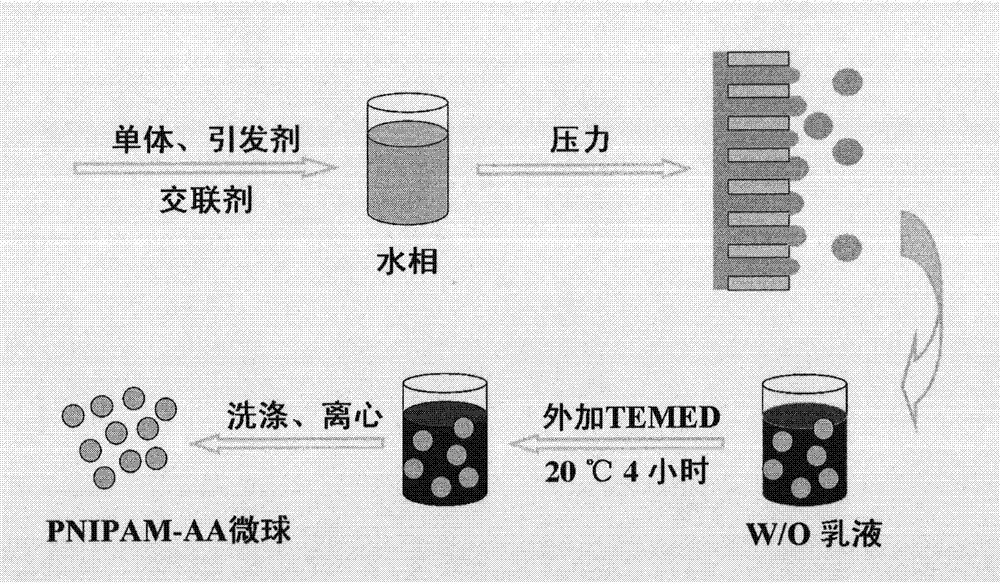

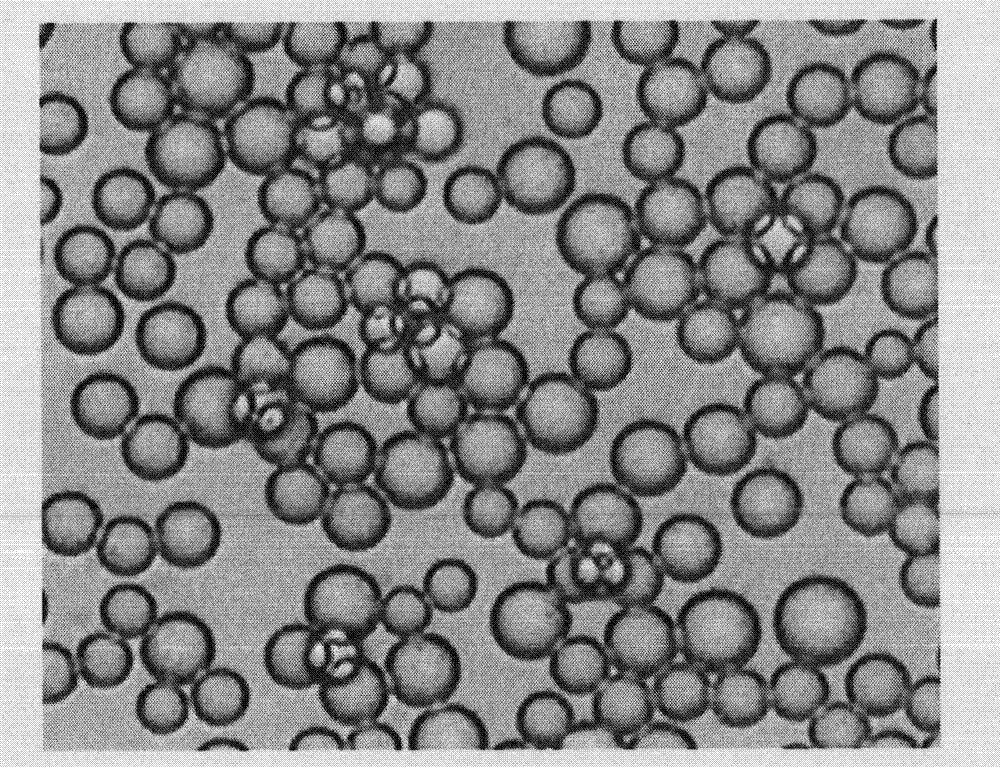

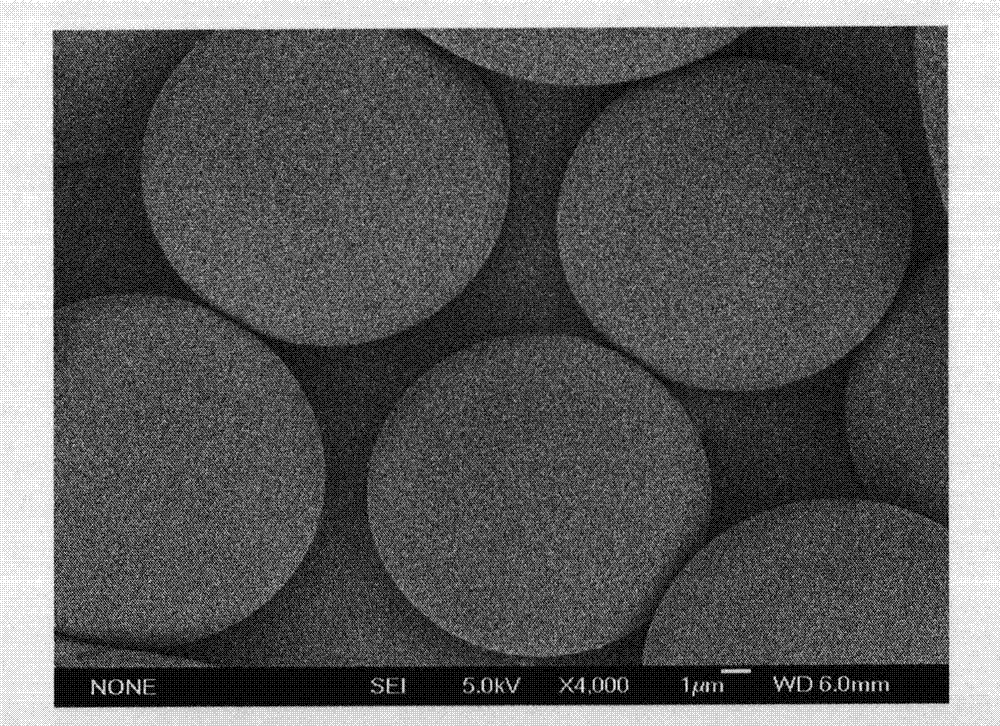

[0039] In the preparation method of the present invention, the W / O emulsion is prepared by a microporous membrane emulsification method, the particle size of the gel microspheres can be adjusted by adjusting the pore size of the hydrophobic microporous membrane, and the particle size of the gel microspheres is uniform. The particle size distribution coefficient calculated by the following formula is not more than 20%:

[0040] C.V.={[∑(di-d)2 / N]1 / 2 / d}×100%

[0041] In the formula, C.V. represents the particle size distribution coefficient; di represents the diameter of each nano-microsphere; d represents the number average particle diameter of the microspheres, d=Σdi / N; N is the number of microspheres used to calculate the particle size, and N≥200 pieces.

[0042] Method provided by the invention comprises the steps:

[0043] 1) Provide an aqueous solution in which the water-soluble monomer N-isopropylacrylamide, acrylic acid, initiator, and crosslinking agent are dissolved as...

Embodiment 1

[0069]Add 10g of N-isopropylacrylamide into 100ml of n-hexane, heat it to 40°C to dissolve it, and then cool it down slowly. After crystallization, filter it with suction, put it in the refrigerator overnight, filter it the next day to get a filter cake, and recrystallize it with n-hexane for later use. A hydrophobic glass membrane was used as the microporous membrane. Accurately weigh 0.85g of refined N-isopropylacrylamide, 0.15g (15wt% of total monomers) acrylic acid, 0.05g (15wt% of total monomers) methylenebisacrylamide MBA in 8ml deionized water, and stir well. Then add 0.05g (3wt% of the total monomer amount) initiator APS, add deionized water to a total volume of 10ml, and magnetically stir to make it fully dissolved. Take 80ml of cyclohexane and 20ml of chloroform and mix evenly, add 5.0g (5% g / ml of oil phase mass) of emulsifier SPAN80, and stir magnetically to make it evenly mixed. Under the nitrogen pressure of 2.5KPa, the water phase is pressed into the oil phas...

Embodiment 2

[0071] Poly(N-isopropylacrylamide-co-acrylic acid) microspheres were prepared using the same device and method as in Example 1, the difference being that the total amount of N-isopropylacrylamide and acrylic acid was kept at 1 g, N-isopropylacrylamide The amount of propylacrylamide was changed to 0.95g (95% by weight of the total monomer), and the amount of acrylic acid was 0.05g (5% by weight of the total monomer), resulting in poly(N-isopropylacrylamide-co-acrylic acid) The average pore diameter of the microspheres is 27.04 nanometers, and the average particle diameter of the microspheres is 24.92 micrometers. The C.V. is 14.47%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com