Dehumidifier

A technology for dehumidifiers and heaters, applied in the field of dehumidifiers, can solve the problems of high cost of dehumidification process and inability to realize the utilization of waste heat in the system, so as to achieve the effect of reducing operating costs and realizing the utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

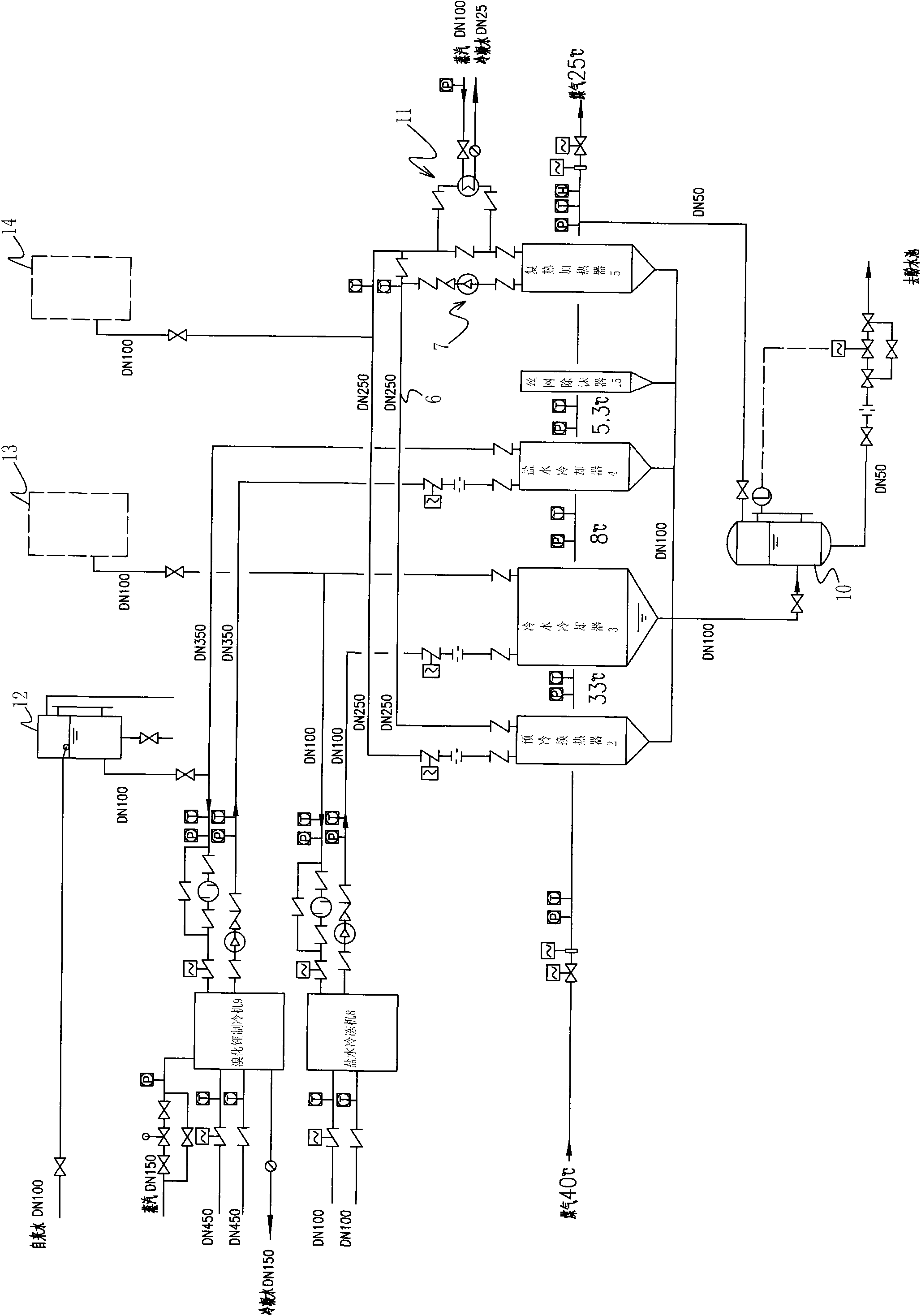

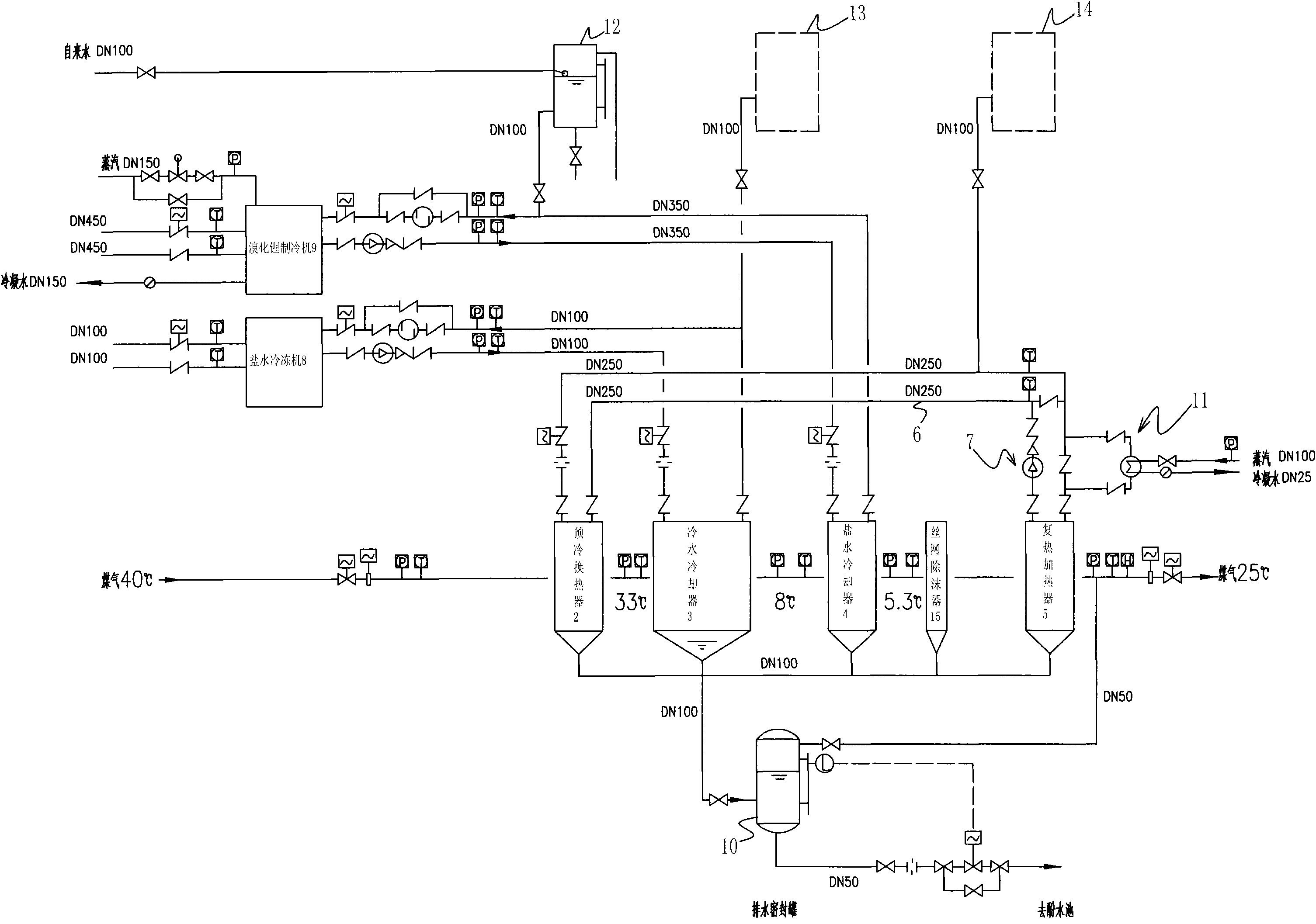

[0020] A dehumidifier comprising a housing and a pre-cooling heat exchanger 2, a cold water cooler 3, a brine cooler 4 and a reheating heater 5 arranged in the housing and sequentially connected, characterized in that the pre-cooling The internal medium of the cold heat exchanger 2 and the reheating heater 5 is connected through a circulation pipe 6, and a self-circulation pump 7 is also arranged on the circulation pipe 6, a brine refrigerator 8 is also connected on the cold water cooler 3, and a brine cooler 4 is also connected A lithium bromide refrigerator 9 is connected, the cold water cooler 3 is also connected with a drainage sealing tank 10, the circulation pipe 6 is also provided with a steam-water heat exchanger 11, and an expansion tank 12 is also arranged between the brine cooler 4 and the lithium bromide refrigerator 9 An expansion tank two 13 is also arranged between the cold water cooler 3 and the brine refrigerator 8, an expansion tank three 14 is also arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com