Liquid sample defoamer

A liquid sample and bubble remover technology, which is applied in the preparation of test samples, etc., can solve the problems of large reverse movement resistance of bubbles, large flow resistance of liquid samples, affecting detection, etc., reducing the retention time, facilitating re-sampling, The effect of improving the defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

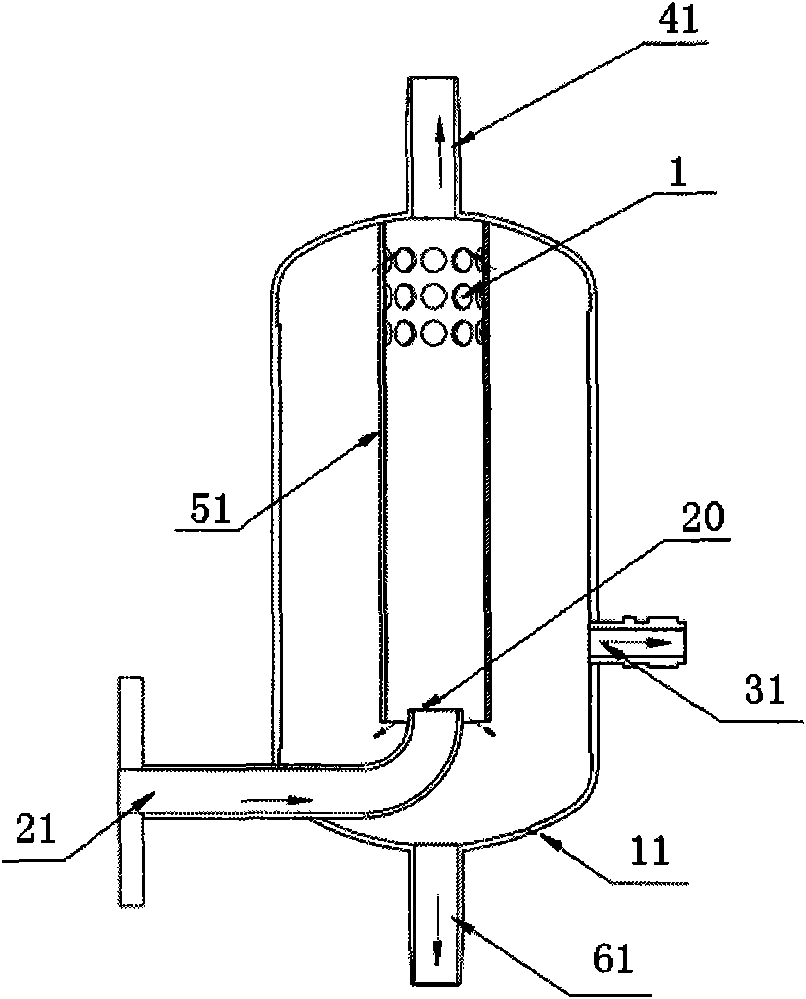

[0041] see figure 2 , a liquid sample defoamer, including a tank 11, a sample tube 21, a sample outlet 31, an exhaust port 41, an air duct 51 and a sewage outlet 61.

[0042] The exhaust port 41 is arranged at the top of the tank body 11 , the sewage outlet 61 is arranged at the bottom of the tank body 11 , and the sample outlet 31 is arranged at the side of the tank body 11 .

[0043] Both ends of the air guide tube 51 are open, and the upper end is connected with the tank body 11 , and the inside of the air guide tube 51 communicates with the exhaust port 41 . The hole 1 is provided in the upper part of the air duct 51 . The lower end of the air duct 51 is suspended.

[0044] One end of the sampling tube 21 is the sampling port 20 , and this end goes deep into the inside of the gas guiding tube 51 from the bottom of the gas guiding tube 51 , so that the liquid sample can directly enter the gas guiding tube 51 through the sampling port 20 of the sampling tube 21 . The pos...

Embodiment 2

[0052] A liquid sample defoamer, which is different from Embodiment 1 in that: one end of the sampling tube passes through the side of the air guide tube and goes deep into the air guide tube.

Embodiment 3

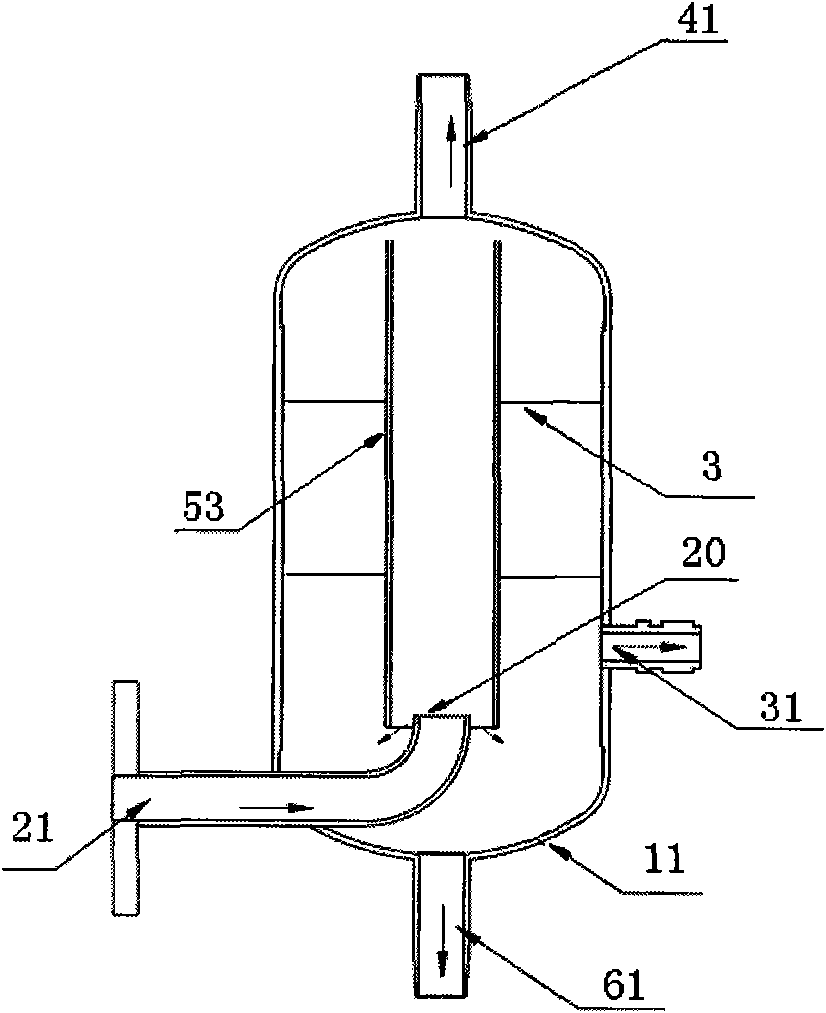

[0054] see image 3 , a liquid sample defoamer, different from Embodiment 1:

[0055] The air guide tube 53 is fixed on the tank body 11 through the fixing frame 3 , and the upper end is kept at a certain distance from the top of the tank body 11 . Bubbles in the liquid sample outside the air guide tube 53 move upward under the action of buoyancy. These bubbles pass through the gap between the air guide tube 53 and the tank body 11 to escape the liquid sample, and then burst and be discharged through the exhaust port 41 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com