Lifting-controllable LED louver strip display screen and manufacturing method thereof

A technology of LED blinds and LED light strips, which is applied in the direction of blinds/movable grilles, static indicators, instruments, etc., can solve the problems of unable to meet the needs of adjusting point distance, unreasonable structure, heavy box weight, etc., and achieve weight Light, light structure, no deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, the utility model is further described. It should be understood that the following examples are only used to illustrate the utility model but not to limit the scope of the utility model.

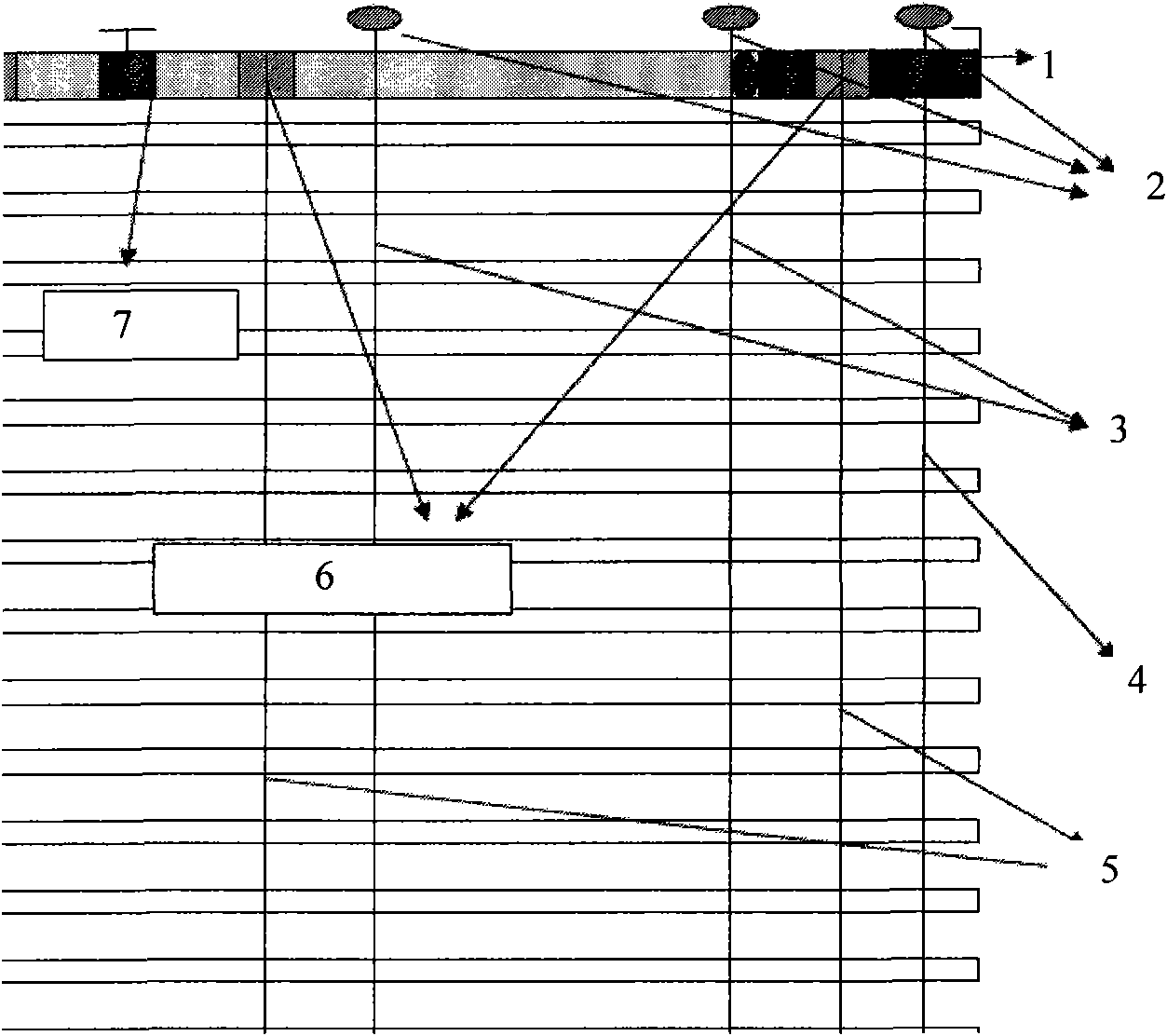

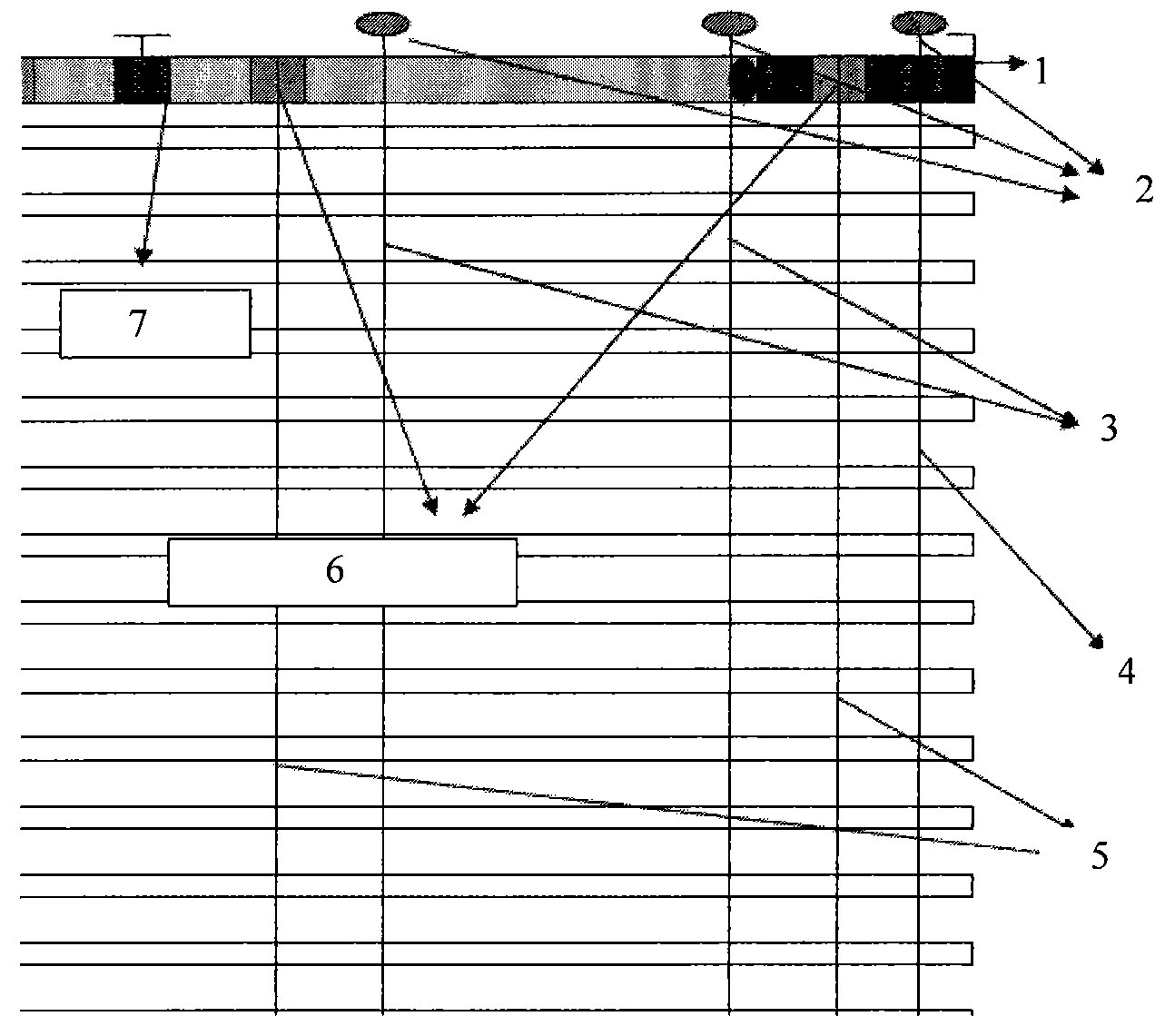

[0030] like figure 1 As shown, the controllable lifting LED louver bar display screen provided by the utility model includes an LED metal material light bar, an LED light bar fixture for connecting and adjusting the LED metal material light bar, and a power supply for driving the LED light bar (not shown in the figure) . The power supply for driving the LED light bar is placed on the back of the light bar fixture and connected to the LED light bar.

[0031] LED light bar fixing parts include fixed louver steel wire, fixed direction steel wire and rising steel wire connected with LED metal material light bar. A hole is punched in the center of the light bar, and there is a steel wire protector on the hole to protect the lifting. The stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com