Slurry mixing system as well as drainage pipe and cleaning method applied to same

A technology for mixing slurry and drainage pipes, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of wasting time and cost, affecting the mixing of mixed slurry, affecting the manufacture of semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

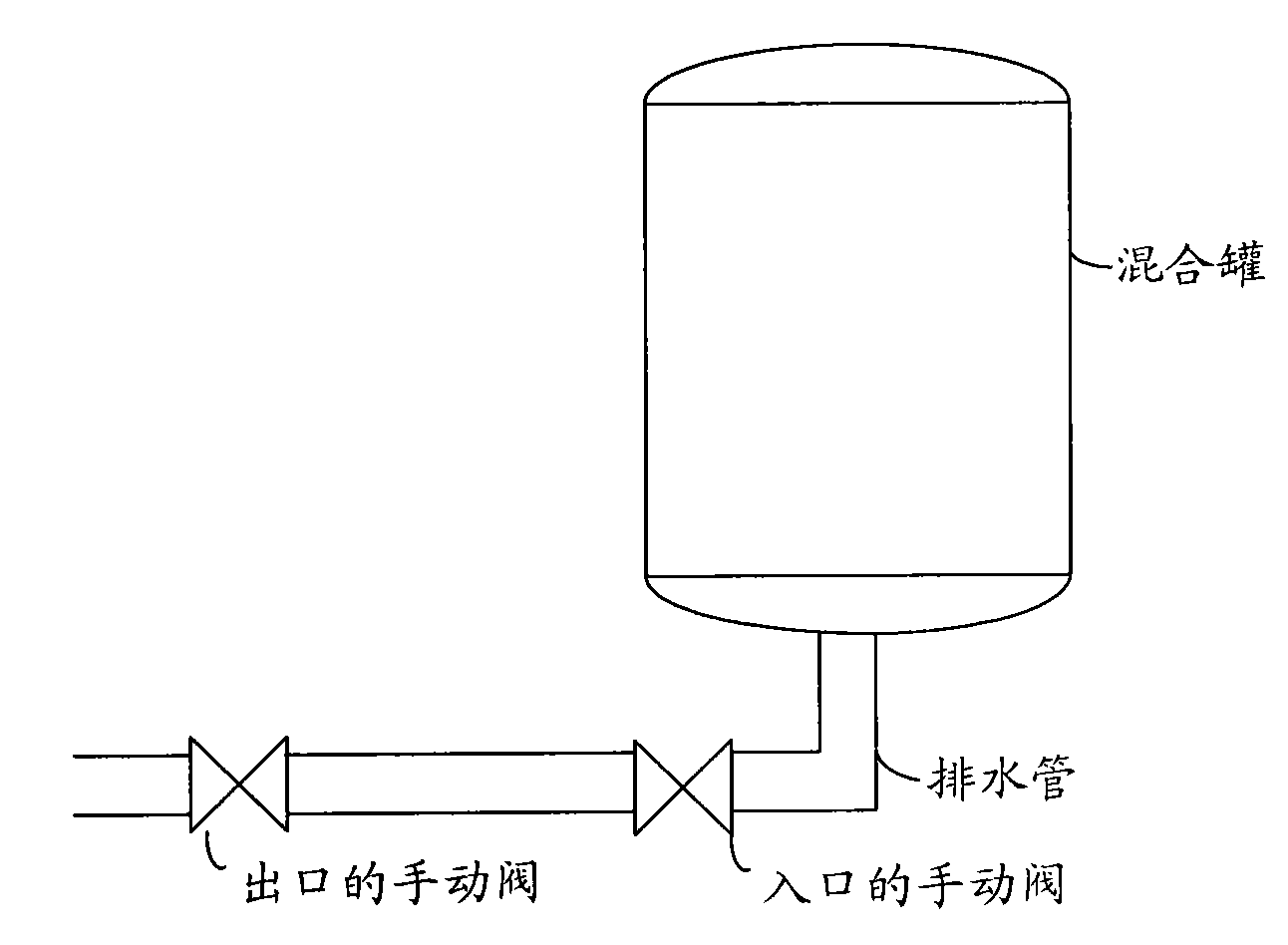

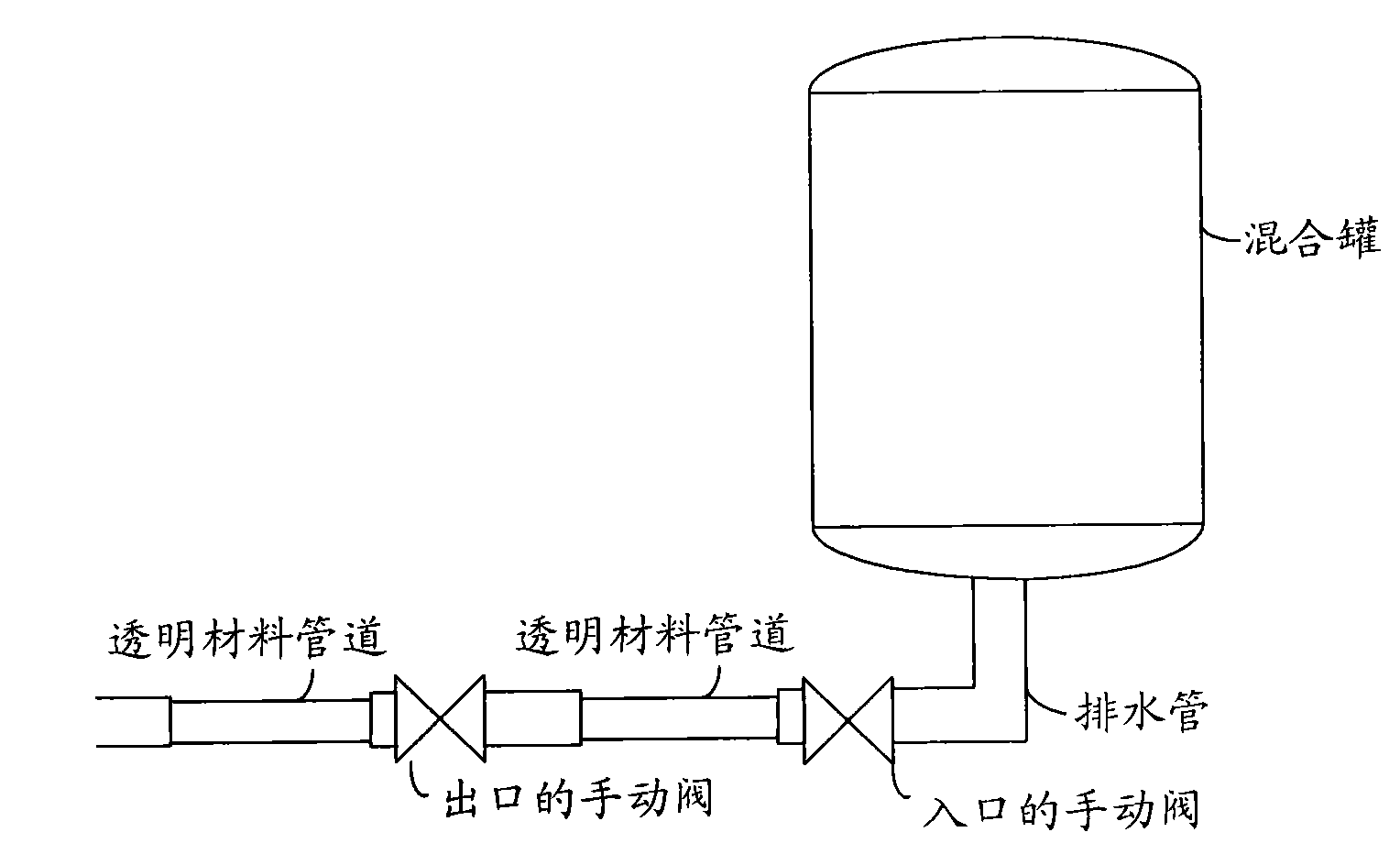

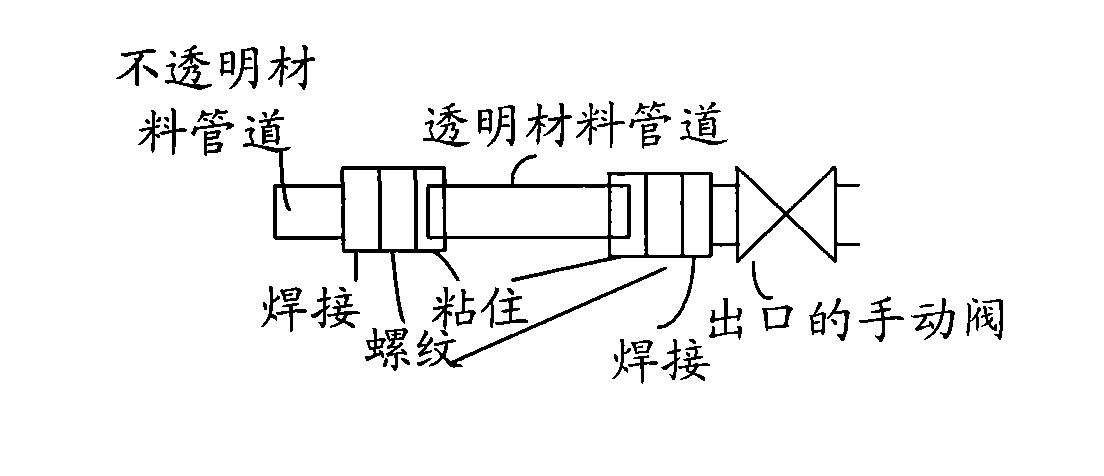

[0035] It can be seen from the prior art that the drainage pipes in the mixed slurry system can only be cleaned regularly or after they are completely blocked, and it is impossible to determine whether to clean them according to the current state of the drainage pipes. This is because the drainage pipes It is made of PP material, which is a non-transparent material, so it is impossible to monitor the amount of crystallization of the drain pipe in real time. Therefore, in order to clean the drainpipe timely and accurately, the present invention will not affect the mixing of the next batch of mixed slurry by the mixing tank, will not affect the normal supply of the mixed slurry by the entire mixed slurry system, and will not affect For the fabrication of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com