Gas combustion filter

A filter and gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient gas volume of nozzles, easy blockage of filter nets, small filter area, etc., to achieve sufficient supply, stable combustion, and increased filtration area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific structure and implementation of the present invention will be described in detail in conjunction with the accompanying drawings.

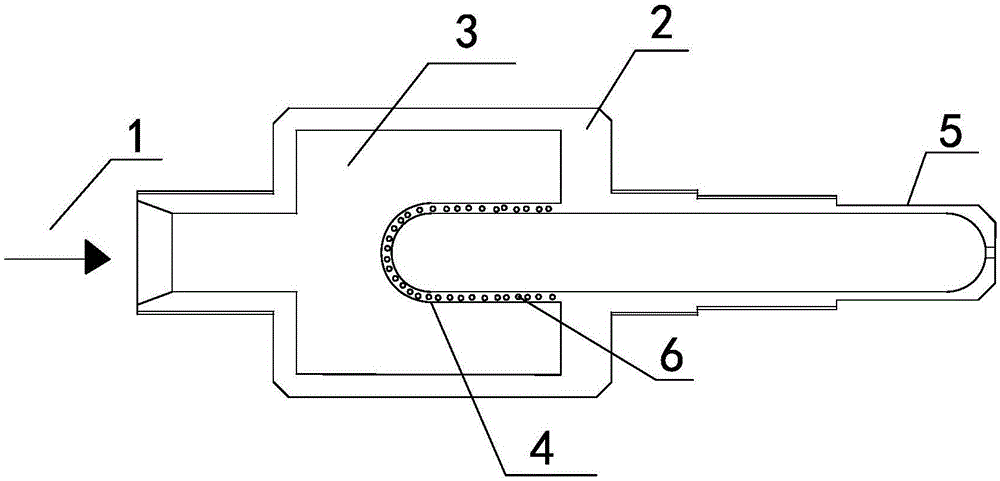

[0024] see figure 1 , which is a structural schematic diagram of a gas combustion filter according to an embodiment of the present invention. The filter includes a housing 2, which is rectangular in shape and whose size is much larger than the diameter of the gas delivery pipeline, and which is filled with a filter screen for filtering gas 3. There are openings at both ends of the housing 2, one of which is connected to the gas delivery pipeline, and an elbow 4 protruding toward the inside of the housing 2 is fixed at the opening at the other end. In this embodiment, the elbow 4 is a U-tube. Gas outlets 6 after the purifier are distributed on the elbow 4 of the filter. The shape, size and distribution of the air outlets 6 are not limited, and the optimal size is a circular outlet uniformly distributed along the elbow. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com