Portable hydraulic steel bar bending machine

A kind of steel bar bending and portable technology, applied in the field of building construction tools, can solve the problems of easy fatigue of workers, high bending labor intensity, unable to meet the requirements of design specifications, etc., and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

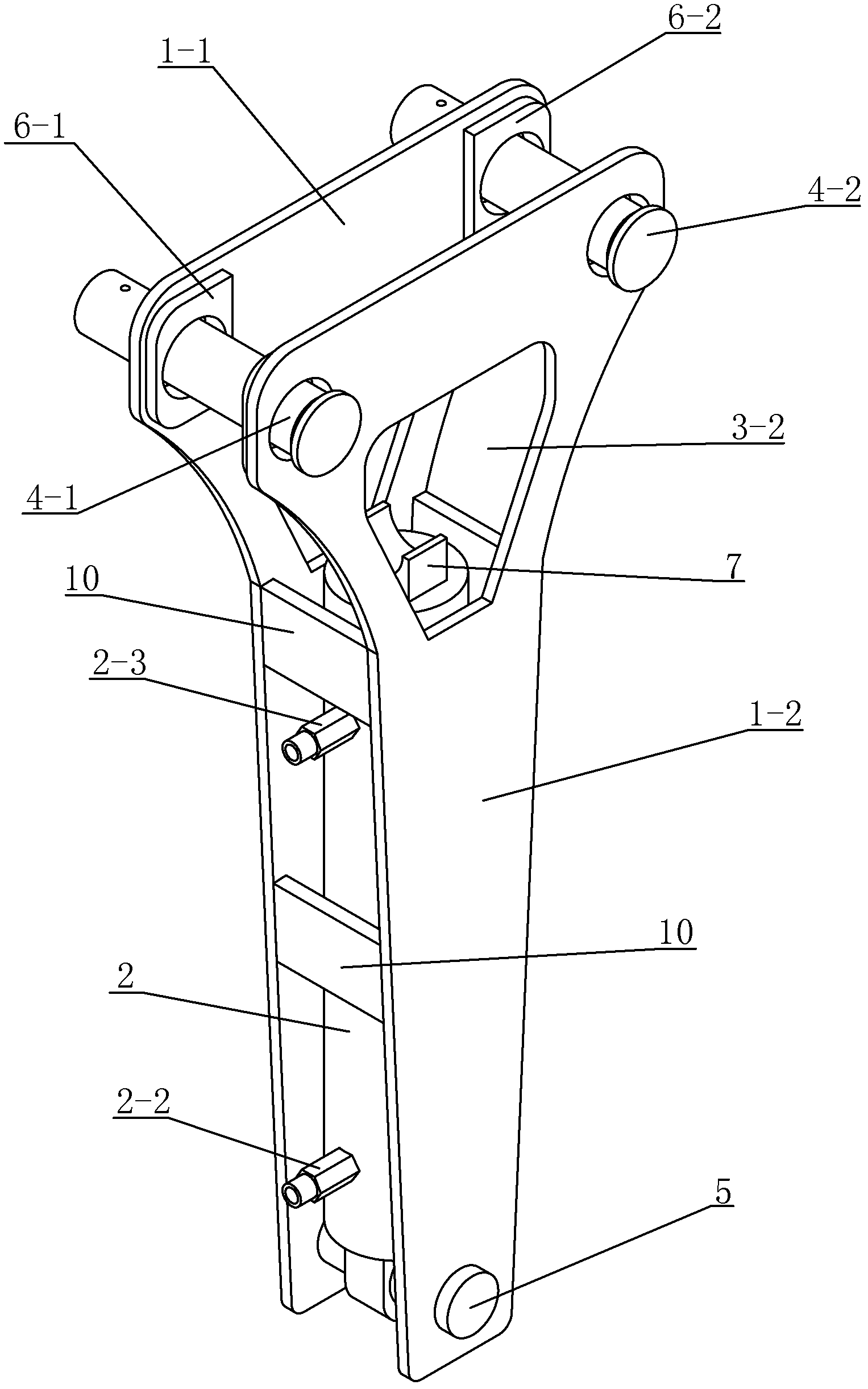

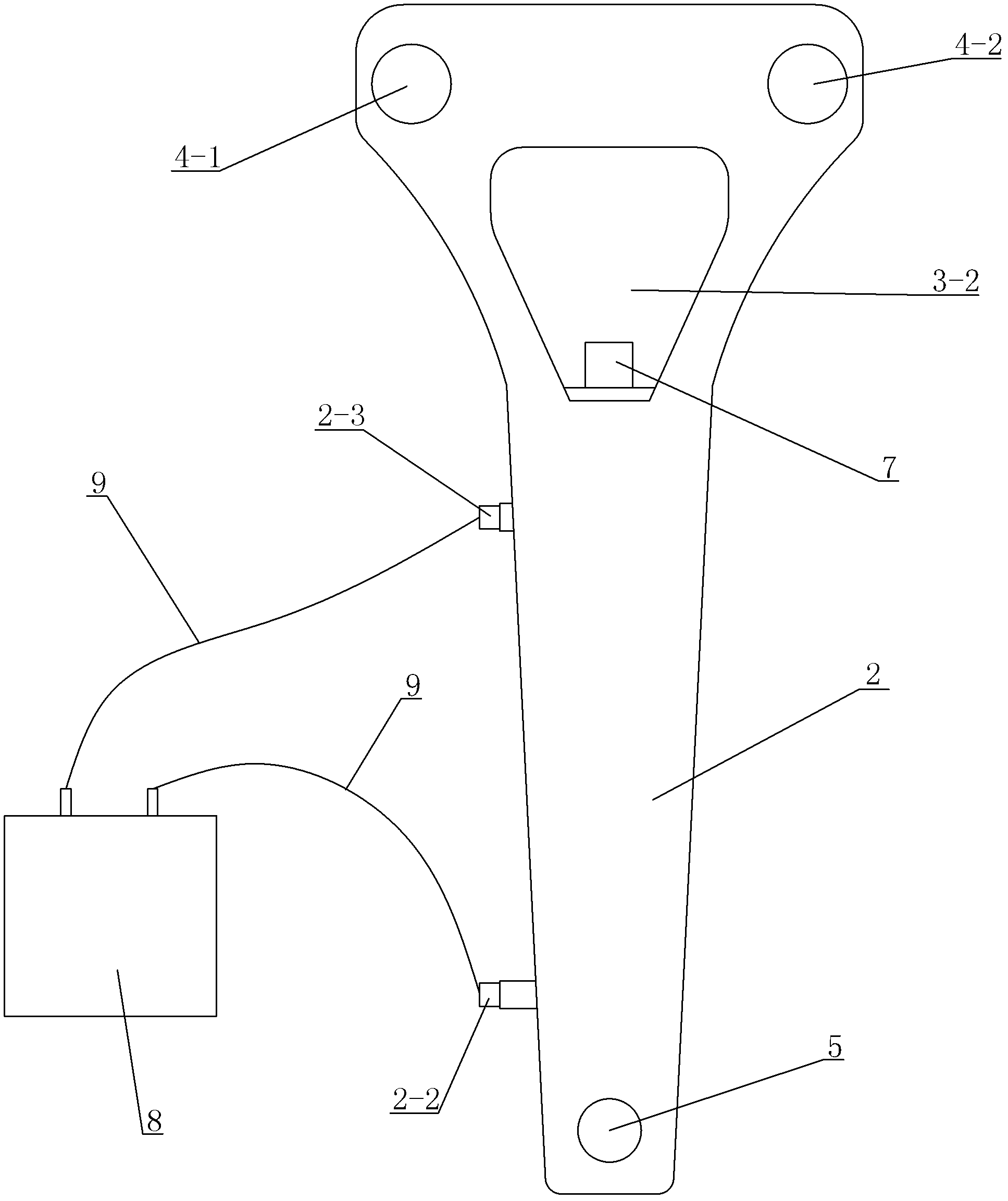

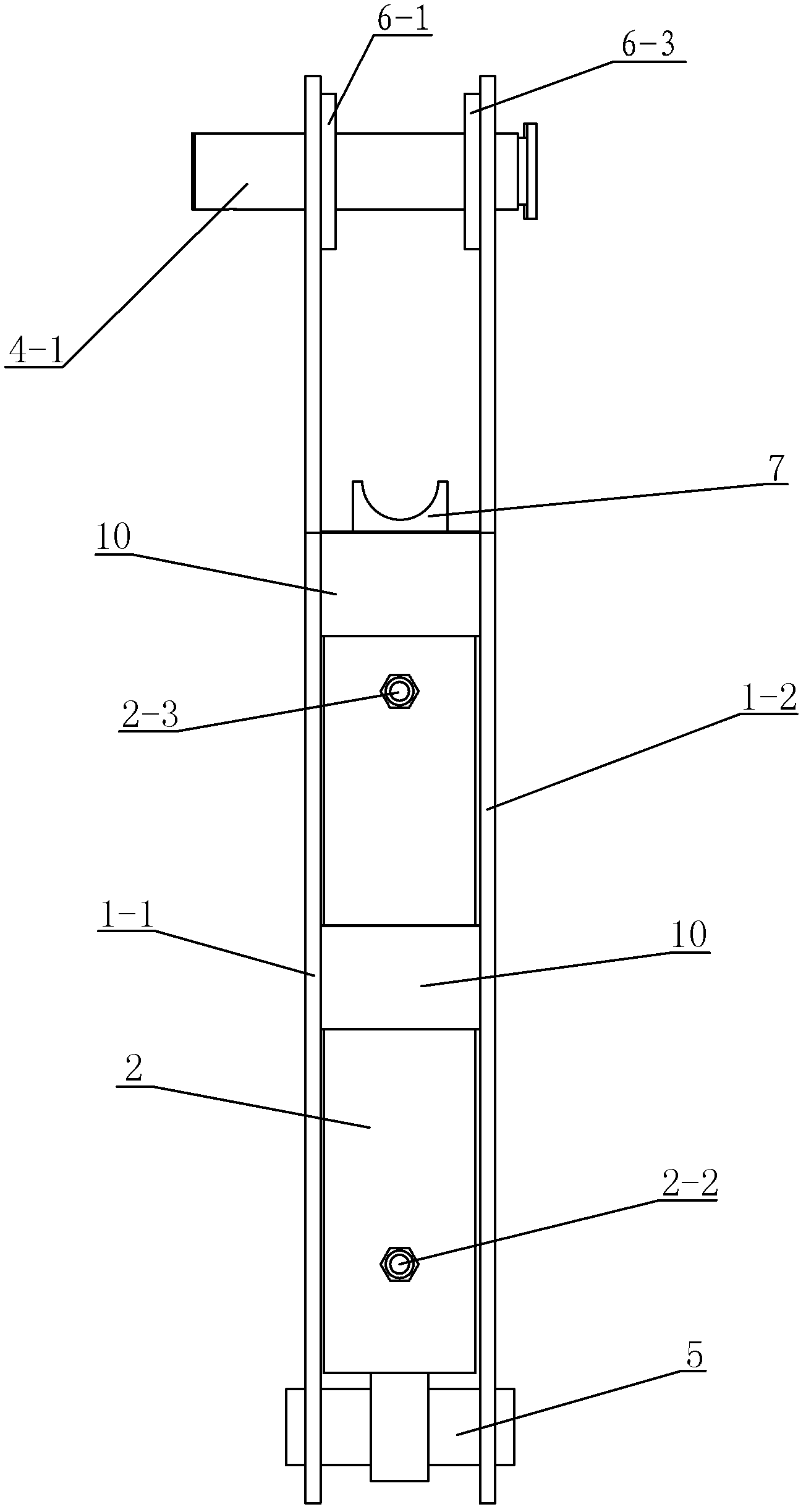

[0041] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5A portable hydraulic steel bar bending machine shown includes a support frame and a hydraulic cylinder 2, the support frame includes a left clip 1-1 and a right clip 1-2 arranged in parallel, and the hydraulic cylinder 2 is arranged on the left clip Between the sheet 1-1 and the right clip 1-2, the bottom of the hydraulic cylinder 2 is fixedly connected with the lower ends of the left clip 1-1 and the right clip 1-2 through the fixing piece 5, and the piston of the hydraulic cylinder 2 One end of the rod is fixedly installed with a support limiter 7 for supporting the steel bar to be bent and preventing the steel bar to be bent from moving left and right during the bending process. The limit forming part 1 4-1 and the limit forming part 2 4-2 are used to limit the two ends of the bending part of the steel bar to be bent and bend the steel bar to be bent. The limit forming part 1 4-1 and The limiting form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com