Pure electric vehicle control unit calibration system based on CAN (controller area network) bus and calibration method

A vehicle controller, CAN bus technology, applied in the direction of vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problem that there is no calibration method for the vehicle controller of pure electric vehicles, and the vehicle controller of pure electric vehicles cannot Calibration and other problems, to achieve the effect of fast calibration and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

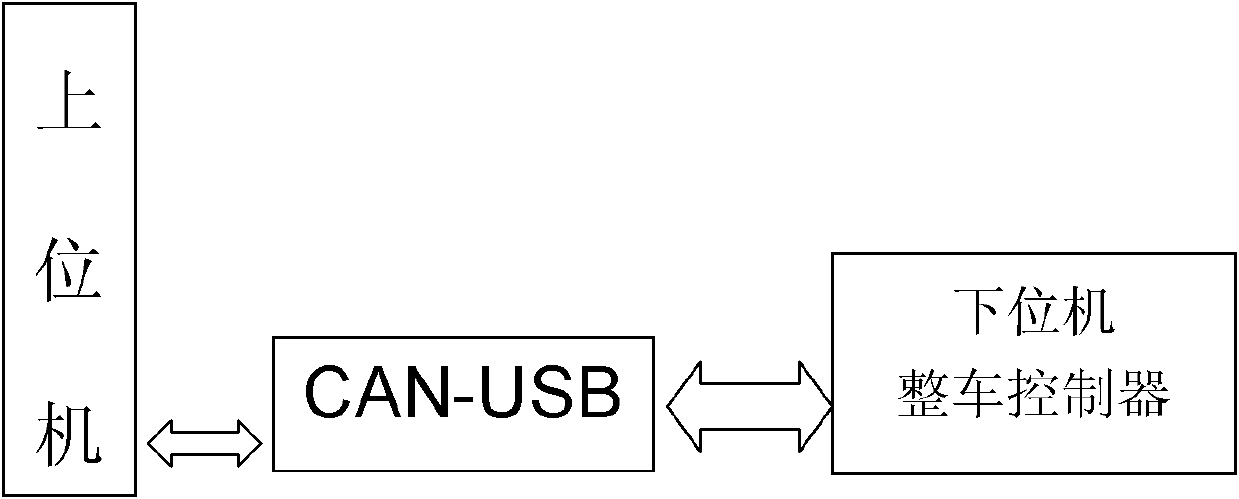

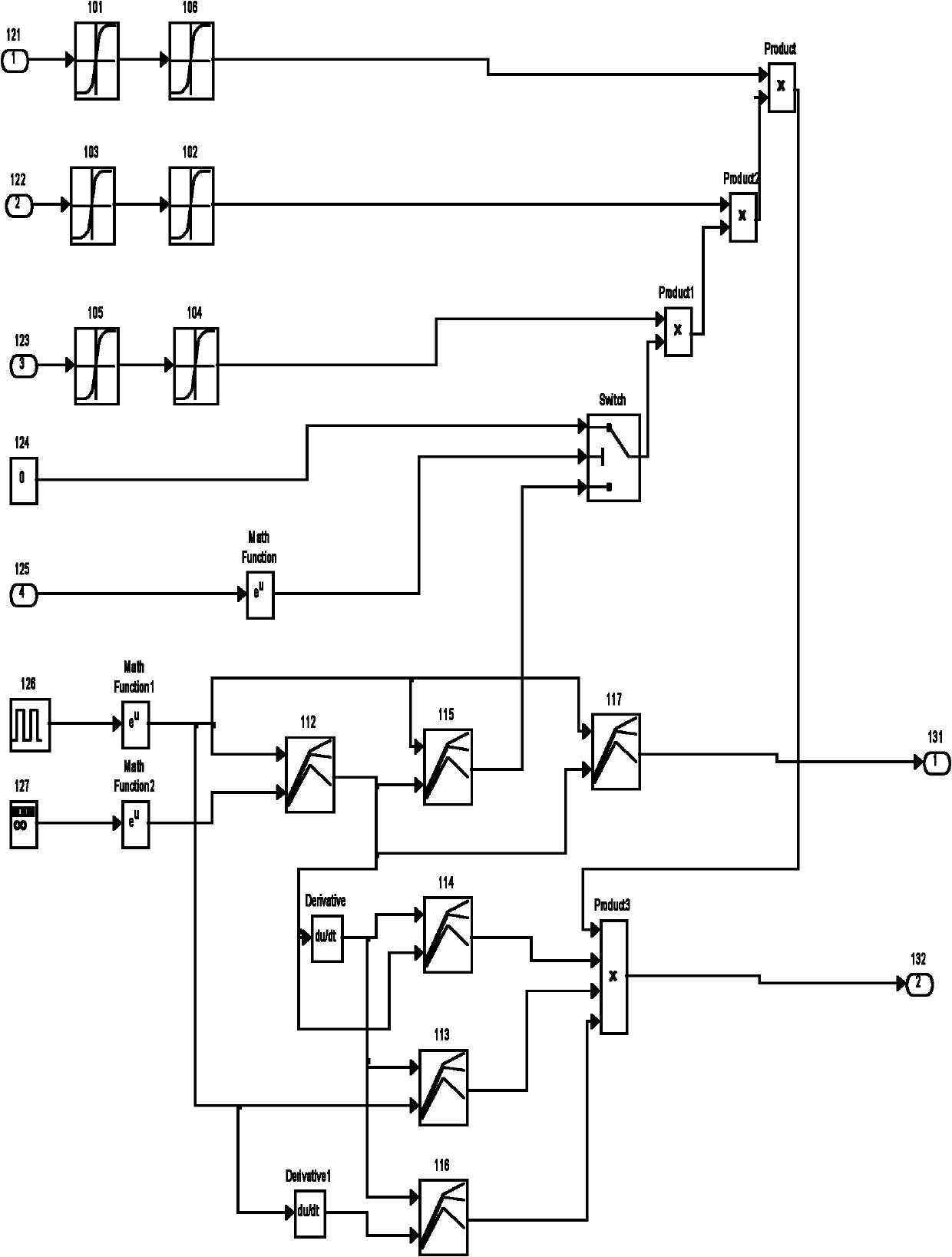

[0047] Refer to attached picture Figure 1-5 The present invention is described in detail. Such as figure 1 As shown, the system architecture of the present invention includes a host computer based on the WINDOWS system, which is connected to a USB-to-CAN device through its USB interface, and the USB-to-CAN device has a CAN bus interface that conforms to the CAN2.0B specification. The lower computer is connected to a CAN bus interface specially used for calibration. Considering the short CAN bus for calibration and the versatility of the CAN-to-USB device used for calibration, the two 120Ω terminal resistors of the CAN bus are all built in the lower computer. Calibration The communication protocol of the process conforms to the CCP specification.

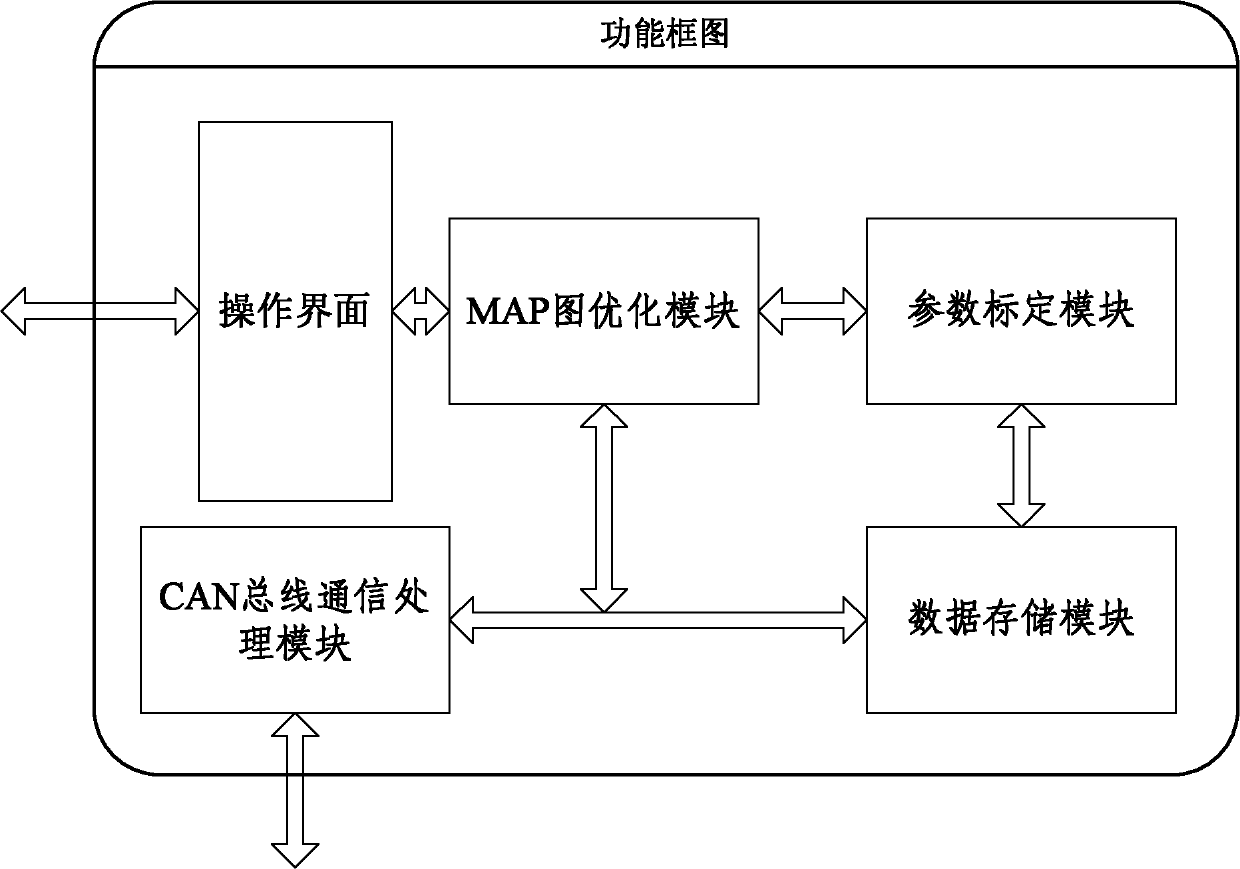

[0048] Such as figure 2As shown, the pure electric vehicle vehicle controller (VCU) calibration system based on the CAN bus includes an interconnected host computer and a lower computer, and the host computer includes: a data st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com