Profiled steel binding machine

A technology of strapping machine and section steel, which is applied to the parts of strapping machinery and strapping materials, etc. It can solve the problems of high maintenance costs, high cost of galvanized steel strips, and mechanical equipment accidents, so as to achieve low manufacturing and maintenance costs and avoid safety problems. The effect of reducing hidden dangers and bundling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

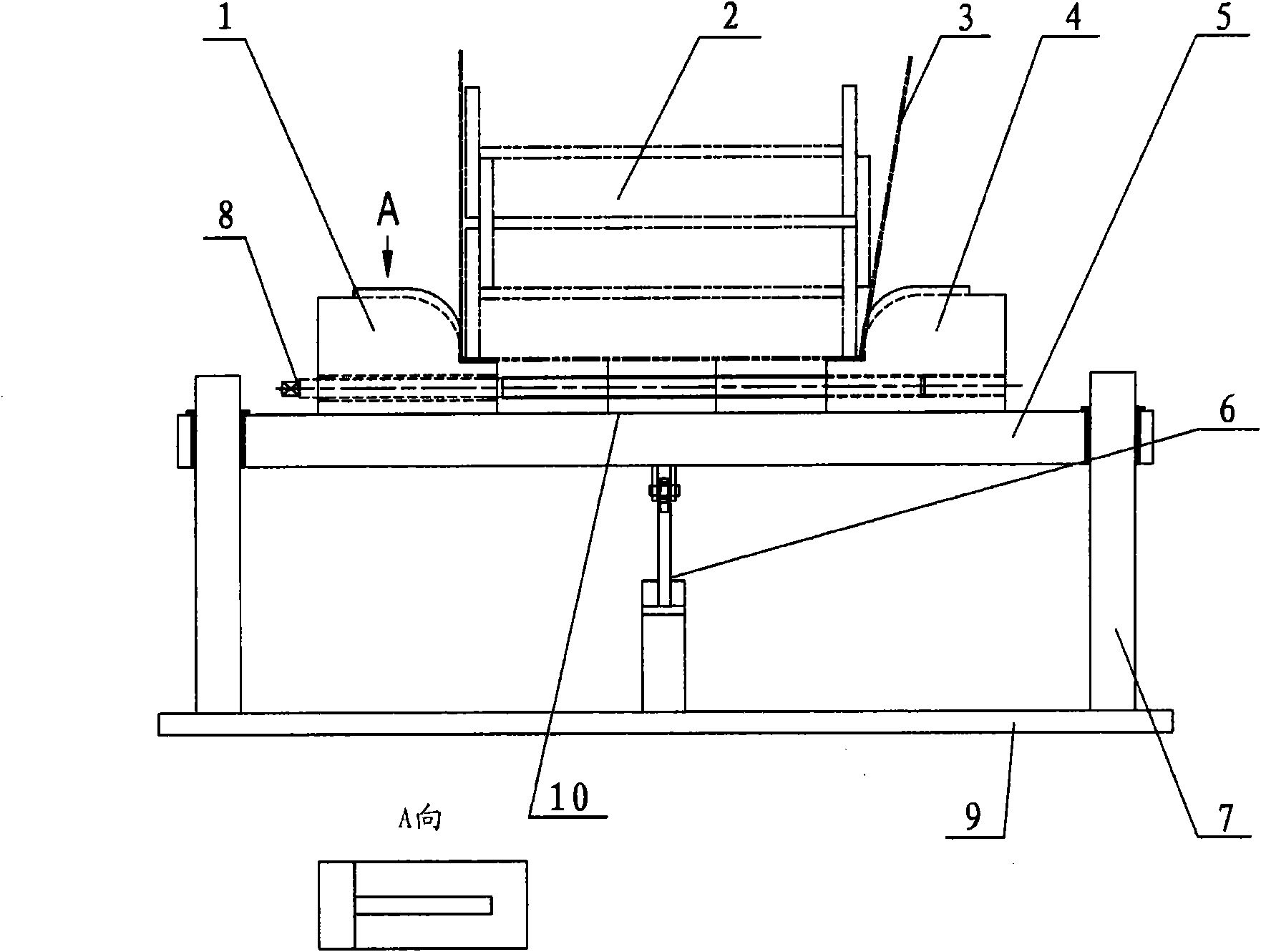

[0033] Now, embodiments according to the present invention will be described in detail, examples of which are illustrated in the accompanying drawings. Hereinafter, the embodiments are described in order to explain the present general inventive concept by referring to the figures.

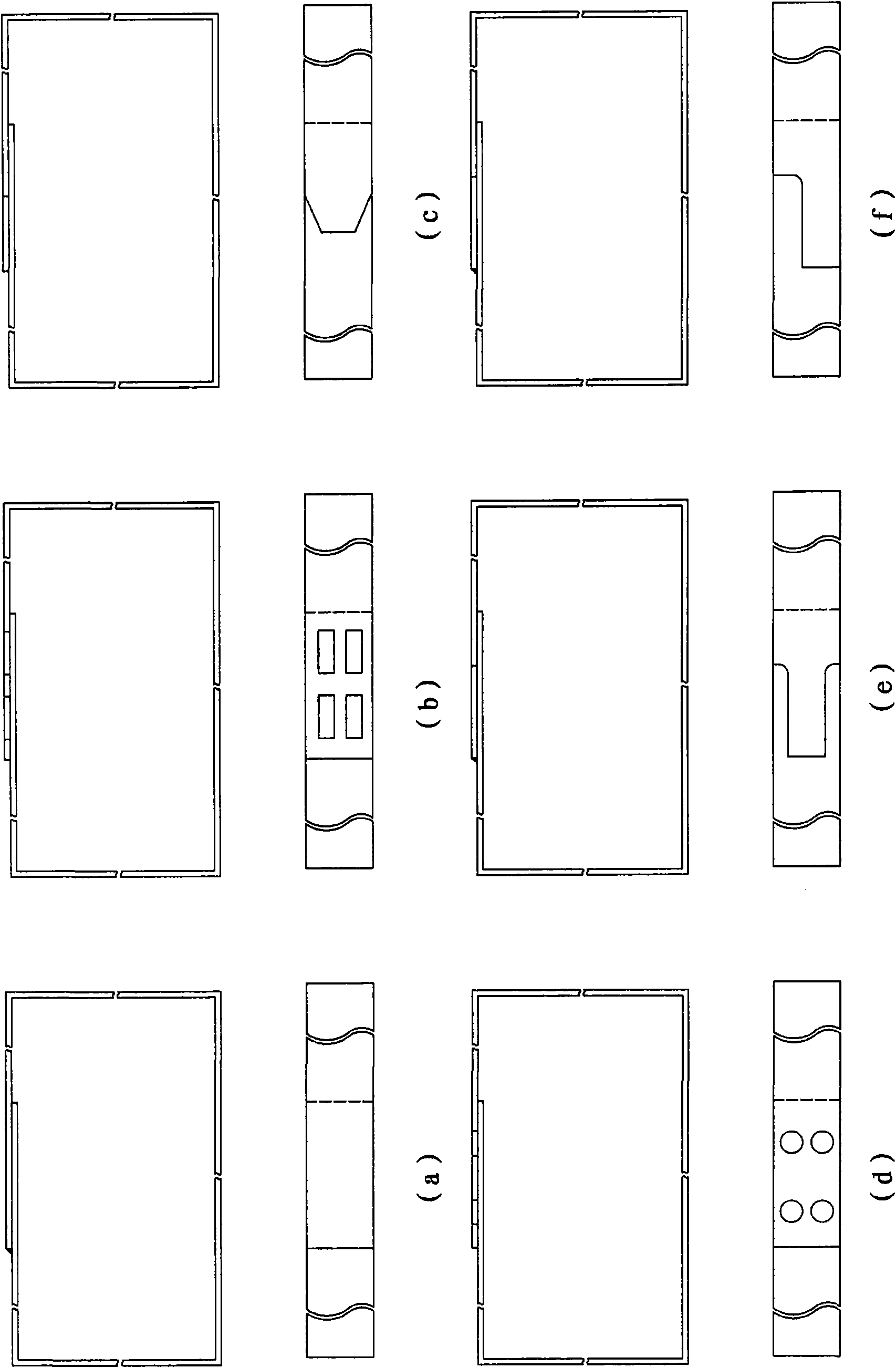

[0034] The section steel binding machine according to the embodiment of the present invention can bind various section steels, for example, H-section steel, F-section steel, channel steel or I-shaped steel and the like. In the following embodiments, H-shaped steel 2 is taken as an example for description.

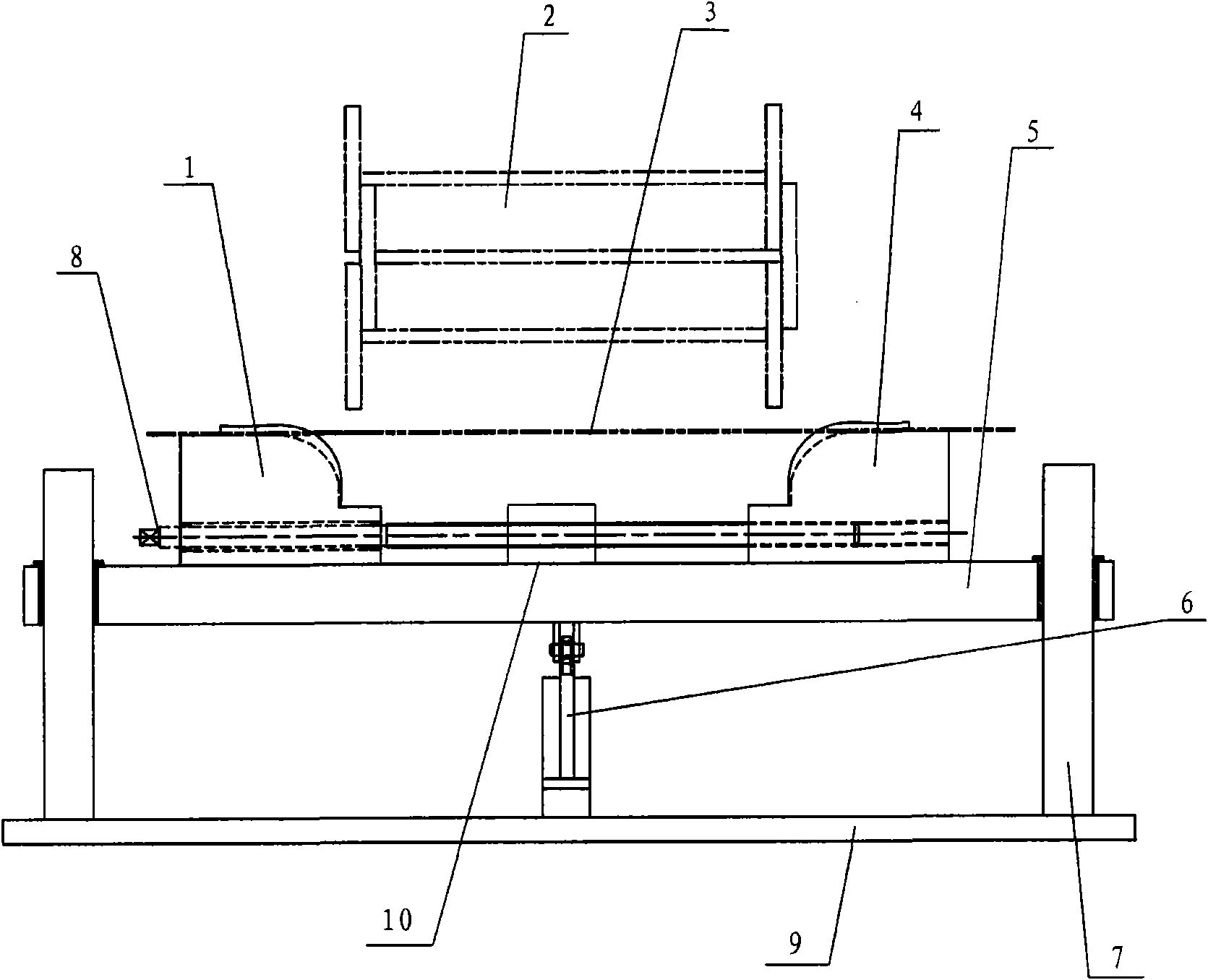

[0035] The section steel binding machine of the exemplary embodiment of the present invention includes pillow seats 1 and 4 , a base 5 , a hydraulic cylinder 6 , a guide rod 7 and a fixed support 9 .

[0036] The fixed support 9 of the section steel binding machine according to the exemplary embodiment of the present invention is located at the lowermost part of the section steel binding machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com