Device and method for grabbing cop yarns by automatic doffing trolley

A grabbing device and automatic doffing technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc. Reasonable location and method, simple mechanical structure, and small range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

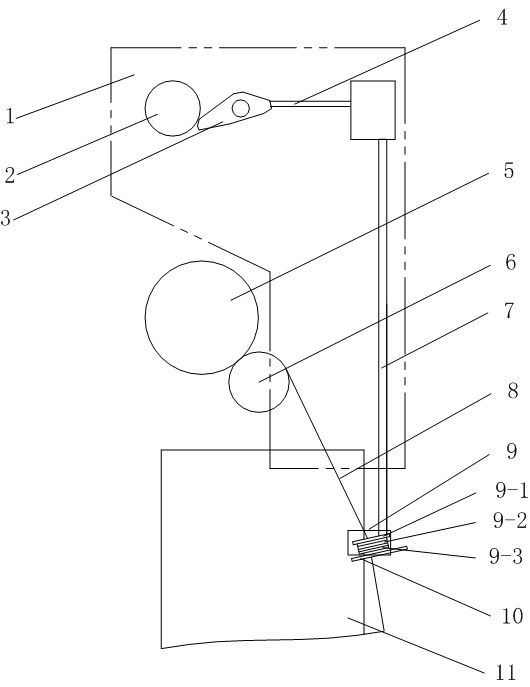

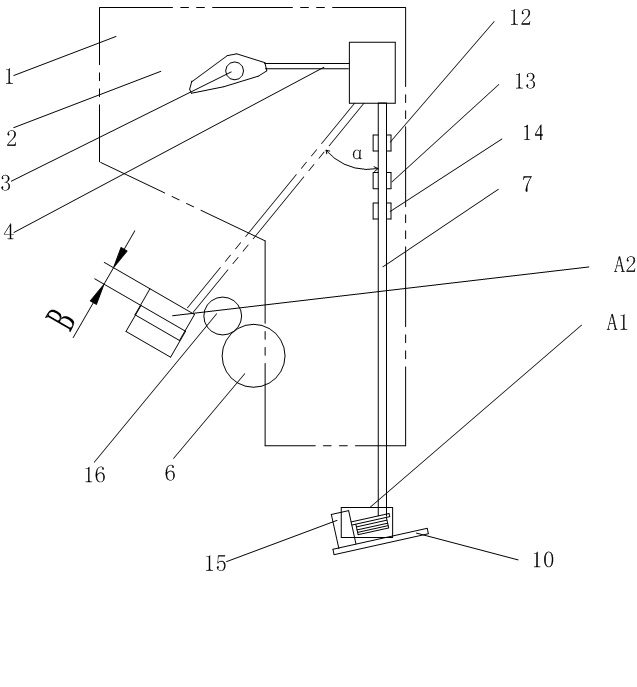

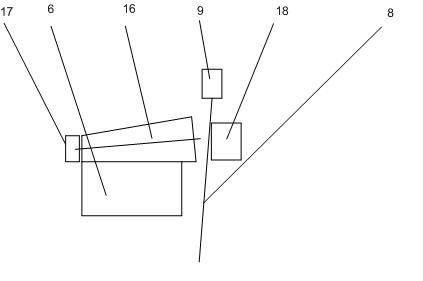

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] see Figure 1-Figure 3 , an embodiment of a device for grabbing cop yarns by an automatic doffing trolley in the present invention, comprising a grabbing device 9 on the doffing trolley 1, a conveying device and its rotary drive mechanism, a yarn clearer on the support 11 and a clearer The yarn guide plate 10, the conveying device is a telescopic arm 7 driven by an independent cylinder, and the grabbing device 9 includes a yarn guide plate 9-1, scissors 9-2 and The yarn gripper 9-3, the yarn clearer guide plate 10 is provided with a grasping positioning plate 15; the rear part of the telescopic arm 7 is provided with a second sensor 13 for detecting the original position of the grasping device 9, and a detection grasping device 9 The third sensor 14 that reaches the position A1 of the grasping positioning plate and the first sensor 12 that detects that the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com