Semi-automatic arch culvert construction template

A semi-automatic and formwork technology, which is applied in the direction of formwork/formwork/work frame, road bottom layer, and on-site preparation of building components. It can solve the problems of affecting appearance, uneven surface, and slow speed, so as to improve construction efficiency and improve The effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

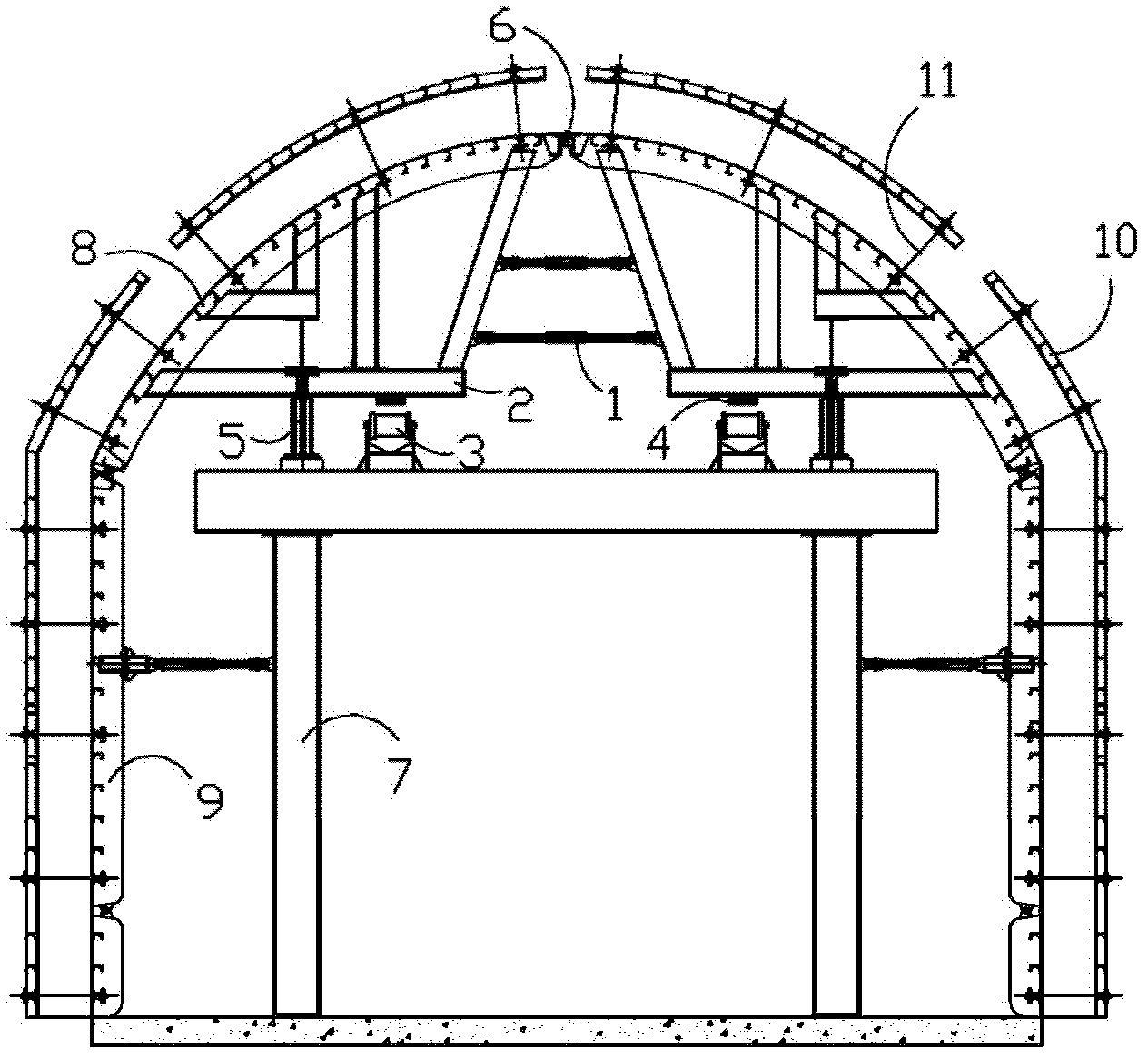

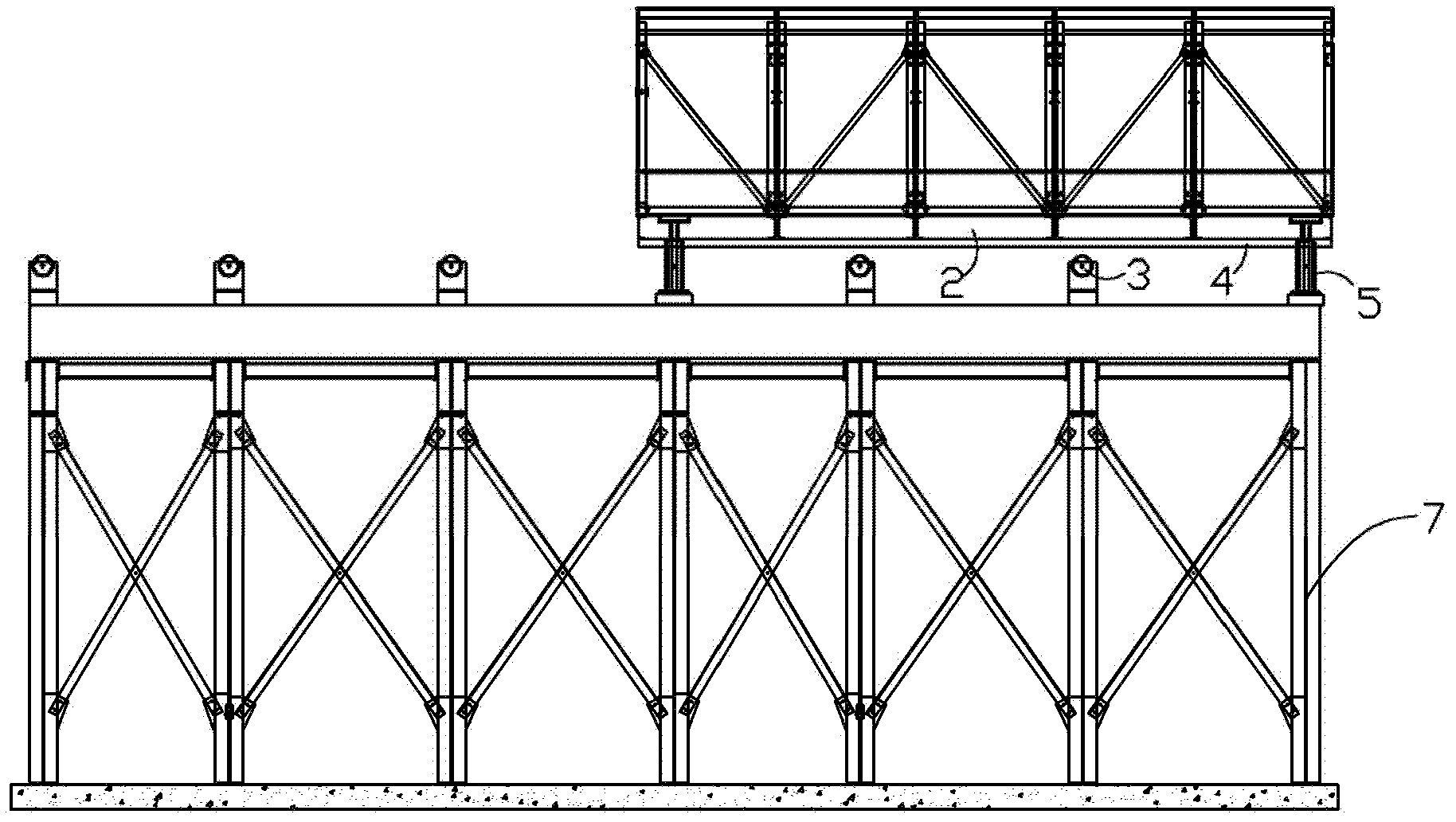

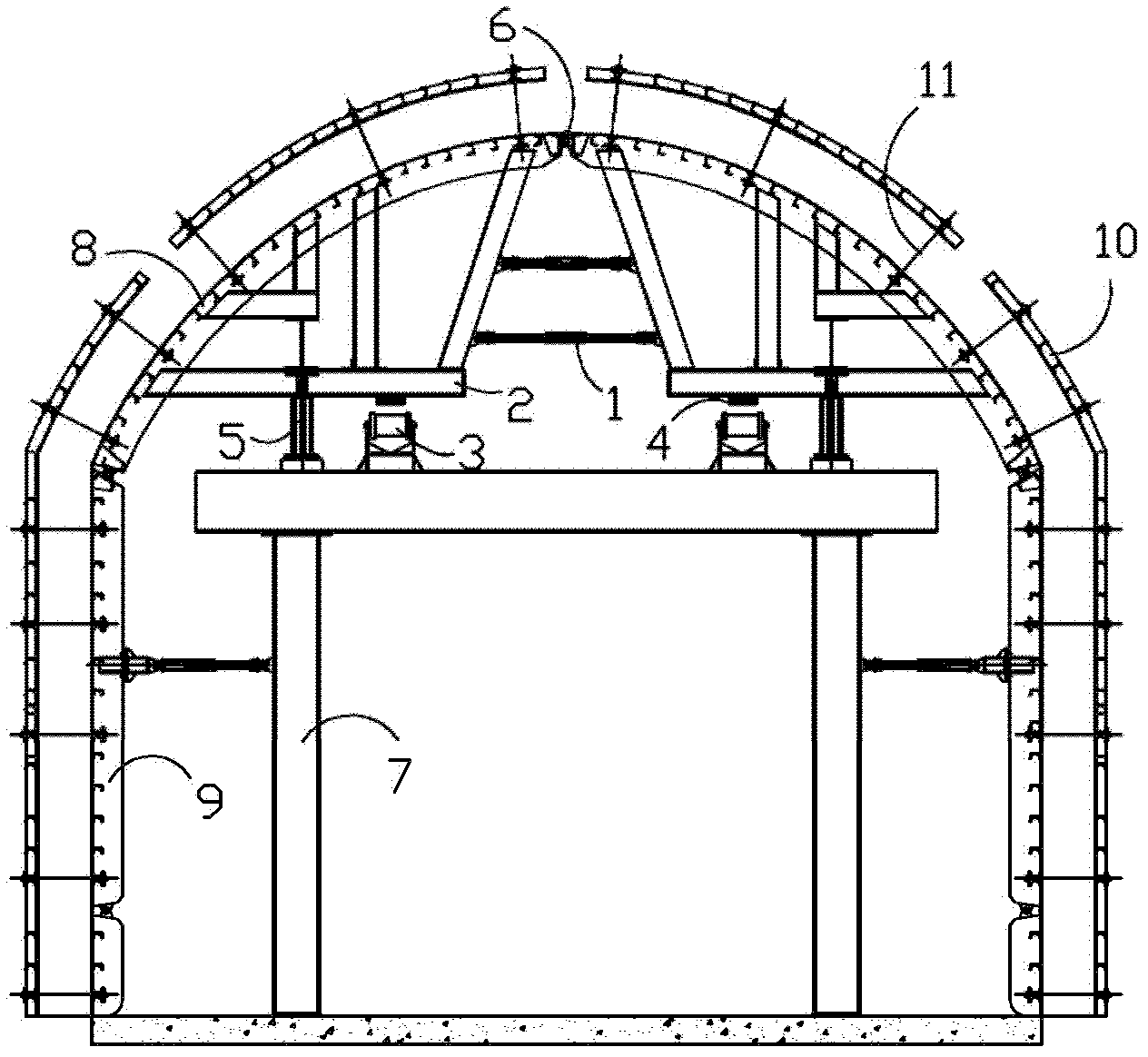

[0025] see figure 1 , figure 2 , in the present embodiment, the door-shaped support 7 is arranged longitudinally, and the longitudinal direction is the length direction of the arch culvert. On the top frame of the door-shaped support 7, two rows of supporting rollers 3 are arranged in parallel in the longitudinal direction; The mold trusses 2 are triangular structures composed of chords and diagonal braces, and the chords are supported by jacking cylinders 5 and rollers 3 fixedly arranged on the top frame of the portal frame 7; The screw 1 with adjustable length is connected between the diagonal braces, and the length of the screw 1 can be adjusted to adjust the expansion degree of the top mold 8;

[0026] The top mold 8 is hinged by steel pins 6 in the middle of the left and right circular arch sections to form a hinge structure; the left and right circular arch sections of the top mold 8 are respectively fixed and welded to the top mold truss 2 on the corresponding side; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com