8 tracks per inch (8TPI) thread tooth shape structure

A technology of thread and tooth shape, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of poor airtightness, low connection strength, and failure to meet engineering technical requirements, etc. High strength and quick buckle-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

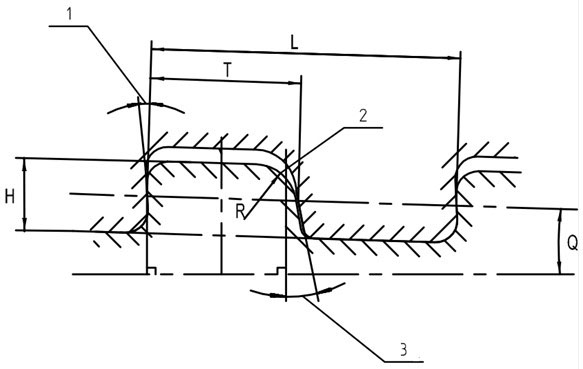

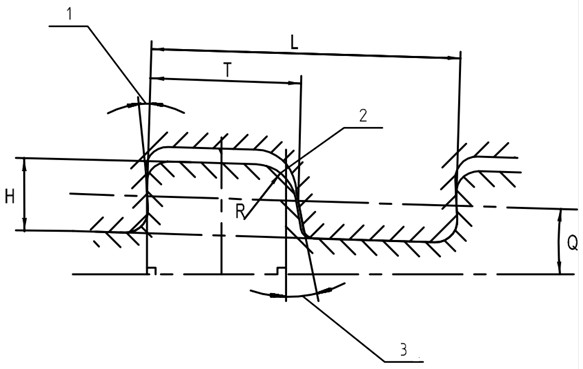

[0016] A kind of 8TPI thread tooth structure provided by the present invention can be used on oil pipe or casing, such as figure 1 As shown, the tooth height H of the thread teeth is 0.80-1.05 mm, the tooth thickness T is 1.50 mm-1.65 mm, and the thread pitch L is 3.175 mm.

[0017] In the design of special threads, tooth height H and tooth thickness T are key data. Reasonable tooth height H and tooth thickness T have a very important influence on the overall strength of the thread. The tooth height H of the present invention is 0.80-1.05 mm, and the tooth thickness T is 1.50mm to 1.65mm. Such tooth height H and tooth thickness T can ensure that the overall strength of the thread reaches the best value.

[0018] The angle of the load-bearing surface in the thread tooth profile is extremely important, which is related to the relia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth height | aaaaa | aaaaa |

| Tooth thickness | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com